|

The

title of this article from the February 1957 edition of American

Modeler was ahead of its time in that it incorporates the "continuous

improvement" theme of 21st century company quality assurance programs.

Old timers are very familiar with the Johnson line of model aircraft

engines. Although materials and process have improved since that

time, it is interesting reading about the engineering thought that

went into the design improvement. Have you ever heard of the

Meehanite process? You can still find these engines on eBay

with a search for: johnson glow engine Johnson Engines

Continue on Improvement Program

If

the new Johnson line of engines looks slightly reminiscent of a

popular engine of a few years ago, namely the Orwick, it isn't just

a coincidence. If

the new Johnson line of engines looks slightly reminiscent of a

popular engine of a few years ago, namely the Orwick, it isn't just

a coincidence. In the hands of a new manufacturer the Johnson

engines should become extremely popular in both free flight and

control line stunt. With only 18 engines available in time for the

1956 Nationals, 28 trophies were won by competitors using this power

plant. Although this is quite an achievement Dynamic Models, Inc.,

is still making refinements to the design to further improve performance.

The first Johnson engine was actually born in October 1955

but these first production jobs did not measure up to the standards

set by Hi Johnson. Rather than continue producing an engine that

they felt could be improved, Dynamic closed their doors and for

the next six months devoted all their energies toward developing

their new "hard cylinder" models. The results of these efforts was

dramatically proven in their first competitive showing.

At the present time Dynamic is producing three sizes: 29, 32, and

35. In the near future a new model with the designation of "stunt"

will be introduced. This engine will have a cubic inch displacement

of approximately .34 and will be developed primarily for control

line stunt and radio control. Dynamic plans to cover the full line

in time, with the exception of 1/2A. The .35 was developed

for combat, free-flight, rat racing and for the stunt flyers who

like quite a bit of speed. A bore of .770 and a stroke of .750 would

indicate that some speed might have been sacrificed for a little

extra power. However the Johnson .35 is lacking in neither. In fact

it peaks at a higher rpm than some of the other engines in its class.

Ruggedness is reflected in its above-average weight of 6.8 oz.

The crankcase, die cast of Alcoa A-380 aluminum, is

designed to take the stress and strain of models that sometimes

try to fly below ground level. For this reason the front face of

the crankcase is left quite heavy as is the journal around the main

bearing. Beam mounting lugs are rugged with mounting holes arranged

to fall directly in the center of a 3/8" motor mount. The three

lugged back plate cover holes can be drilled out for radial mounting

and will fit the micro type tank often used in free flight. The

wall of the back plate has been left 1/8" thick to accommodate drilling

and tapping for pressurized tank combos. Noteworthy features are

the lack of a gasket between the cylinder and crankcase and the

use of a web support in the bypass.

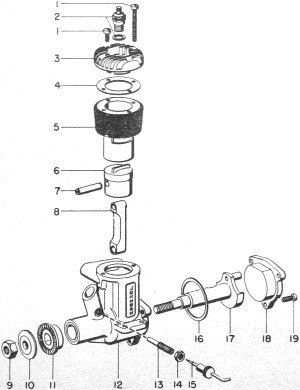

Parts listing 1) head screw; 2) glow plug, gasket; 3) cylinder

head; 4) head gasket; 5) cylinder sleeve; 6) piston; 7) wrist

pin; 8) con-rod; 9) prop-nut; 10) front washer; 11) drive washer;

12) crankcase and bearing ; 13) needle valve spray bar; 14)

needle valve nut; 15) needle valve pin assembly; 16) back plate

gasket; 17) crankshaft; 18) back plate; 19) back plate screw.

Like the crankcase, the head is massive and is die cast from the

same type aluminum alloy. It seats deeply into the cylinder to guard

against blowing head gaskets and features a spherical combustion

chamber which matches the domed piston. It is held securely in place

by six machine screws, two of which extend down through the fins

thus holding the head and cylinder barrel to the crank-case. That cylinder barrel, the heart of the "hard cylinder models," is

a well guarded secret of Dynamic Models, Inc. and as such they will

not divulge the material used or the process used in heat treating.

They do say though that the cylinder is as hard as hard chrome and

many times as durable since it is integral and not just a plating

process. The superficially hardened surface is .006" deep, leaving

a tough core and eliminating the possibility of brittleness. Any

reworking of the cylinder in the way of hop-up will have to be done

with a hand grinder and emery cloth. Piston is slug type

and exceptionally light for an engine of this size. Material used

is a new process called

Meehanite and porosity of the metal is controlled so that the

side walls are left porous while the dome (top) is dense. This allows

the bearing portion to absorb and hold lubricants during operation.

Do not be alarmed when the compression band takes on a grayish look

after about one hour's running. This is a characteristic of the

material. Although the piston is domed shaped, it also employs a

low straight type baffle which does not interfere with the dome

theory but does do a better job of scavenging. Connecting

rod material is extruded and drawn from 72,000 p.s.i, aluminum of

12% elongation giving a tough hard material with extra long fatigue

life. Slots are cut at both the large and small ends to insure sufficient

lubrication. Crank shaft is machined in one piece

from 4130 chrome-molly aircraft steel. Three holes strategically

placed in the shaft journal act as a pressure lubricating system

for the main bearing. Main bearing is a sintered meehanite with

controlled porosity. It is honed out enough to get into virgin metal.

Hi Johnson claims this bearing will outlast any bearing material

known. Since it is cast into the crankcase any chance of float is

eliminated.

Needle

valve assembly is drilled-straight-through variety and although

the fit is better than most of this type we feel that some improvement

in its design would be beneficial. By design, the spray bar cannot

be turned around thus the needle valve protruding from the right

side of the engine (looking from the front) seems to favor left

handed flipping and use of the right hand for operation of the needle

valve. However being opposite the exhaust port has its advantages

too and perhaps one gets used to its location. During. the tests

we found that although there was no noticeable float, the needle

valve was very critical on adjustment. Running tests

were begun after 1/2 hours of break-in time which seemed quite adequate

for the test engine. As recommended by Hi a 10/6 propeller was used.

Maximum rpm with this was 13,500. This same rpm was also recorded

with a 9/8 prop. Dropping down to a 9/6 prop increased rpm to 14,500.

To test its lugging power we tried an 11/6 wide bladed propeller.

Speed dropped to just below 10,000 rpm and an excessive amount of

vibration was noted. However below 9,000 rpm and above 10,000 rpm

our test engine was quite smooth. Starts were quickly made when

the engine was primed directly into the exhaust port, but it was

not quite as easily restarted when hot.

Articles About Engines and Motors for Model Airplanes, Boats, and Cars:

Posted September 8, 2012

|