|

This treatise on engine idling techniques

is yet another example of how extensive and detailed model aircraft magazine articles

used to be. Maybe refinement in design and production has, over time, yielded engines

that are easier to start and and adjust, and are more reliable in general, but there

are plenty of older engines still in operation, whose owners could benefit handsomely

from the advice offered in this column. It has been my experience that even the newer

engines - particularly those typically purchased by those of us on a limited modeling

budget - still exhibit strange operation at times, so unless you always buy the best

engines on the market, read on... you'll be glad you did. Here is

Part 2.

Although aimed at radio control flyers this valuable data can be of help to

all modelers who own a glow plug powerplant...

Engine Idling Secrets

Researcher Thomasian (far lt.) with Dr. W.A.

Good. First clothes-reel test rig (bwloe); final rig considerably more sophisticated.

Part 1

By Harvey Thomasian

The appearance of glow plugs in engines did much to popularize the model airplane

hobby by eliminating almost all the evils of an ignition system. However, the glow plug

rates low for one condition that the ignition system did well: idle - glow plug engines

do not run happily at low R.P.M.

Hardly any information has been written on idling glow engines because theoretical

knowledge on the subject is limited. Many modelers know how to idle such an engine properly,

but not why.

In this report, we shall try to provide some insight as to the whys and wherefores

and present some information to enable modelers to adjust their engines for an acceptable

idle. We thought achieving an idle would be an easy task, but in studying the subject

seriously, we became convinced that any success was due more to good luck than skill.

This is not a complete how-to-do-it article. Our intent is to explain why and how

different factors affect idle, and we shall endeavor to explain how to best adjust your

engine to make it tick over slowly.

Although engine manufacturers have done much good work to achieve optimum low speed

operation, many factors outside their control make an occasional engine difficult to

idle. Also, engine design and materials have a marked effect. Some of these factors,

or variables, are compression ratio, base compression, glow plug design and material,

engine port timing, cylinder head design, heat balance, fuels, exhaust dampers, intake

throttles, temperature, humidity, altitude.

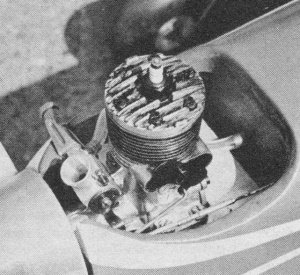

Nose of Thomasian low-winger shows aluminum mounting plate which permitted

different engines to be installed for flight testing.

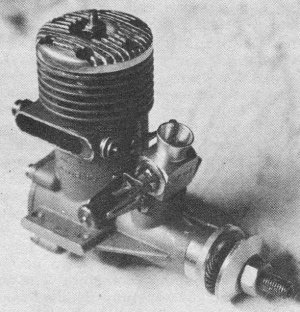

Super Tigre 51 has K&B intake throttle and rotary exhaust damper.

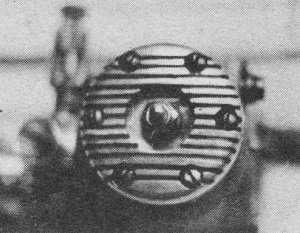

An S. T. 51 with fins cut into cylinder head.

Since these are just some of the factors, you can see it is extremely difficult to

make specific recommendations for all types of engines running on all the glow plugs

and fuels available, for all the different areas in this country with their peculiar

weather conditions. And quite honestly, the biggest variable is the modeler himself.

That's right ... you!

What we wish to emphasize here is that there exists no specific set of recommendations

which can be followed to achieve the desired slow speed. Also, any information provided

shies away from making major changes on engines since the manufacturers have done much

work to give their products a good balance between idle and maximum power.

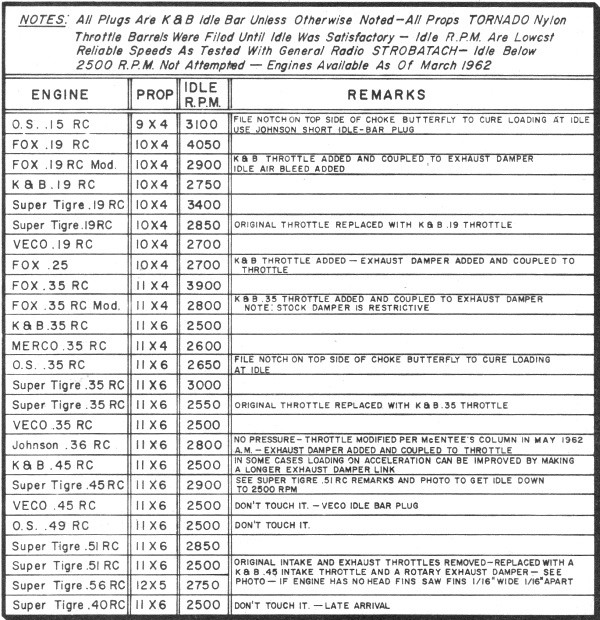

Tests have been run on 31 multi-speed engines of 9 manufacturers. These tests were

conducted in the air with many models, as well as on the ground.

At the beginning of our tests, we had to decide on a target R.P.M. This was selected

as 2500 RP.M. which roughly gives zero prop drag at 14 m.p.h. with a 6" pitch prop and

around 10 m.p.h, with a 4" pitch.

Our ground testing was done by fixing an E-Z Just engine mount to the clothes line.

(This type of clothesline is mounted on a central pole and goes around and around). The

engine angle was adjustable about all three axes, could be mounted anywhere from the

center of the pole out to the end of one of the arms. This contraption was set up to

test the effects of centrifugal force, different engine and tank angles, at various radii,

and at all R.P.M.s, from idle to wide open. Although this rig did not completely duplicate

all flight conditions, actual flight tests showed that results from this whirlygig proved

out. It was especially helpful in determining if the engine would remain idling in a

spin and especially taught us a few things about fuel tanks.

The target R.P.M. figure is one where the engine will run the whole tank at idle:

2 oz. for .15 disp.; 3 oz. for .19 disp.; 4 oz. for .29 disp.; 6 oz. for .35 disp. and

8 oz. for the .45 and up sizes. Also, a severe shock such as a bad touch-and-go landing,

(a bouncy one) or violent maneuvers, will not kill the engine.

All of our trials included temperatures down to 20° F. with some taking place below

0° F. In one instance, we spun a K&B 45 in an old Astro, 23 turns, during a snow

flurry where the ground temperature was 0° F. No, it didn't quit - mind you that this

spin started around 700 ft. - we just couldn't see the airplane at that point!

Anyway, to get to the meat of this thing - what follows sort of rambles on with a

minimum of continuity. We'll mix engine design, a bit of theory and how-to-do-it into

one big bowl.

Firstly, the engine should be in decent shape meaning good cylinder compression, good

crankcase compression, fairly clean of carbon inside, no dirt on the outside either in

the fins or elsewhere, no leaks, either through cracks, gaskets or very sloppy crank

bearings, no binds or tight spots, and reasonably good fitting parts.

To illustrate: carbon in the combustion chamber not only increases compression ratio,

which alters timing, but also acts as an insulator and hinders heat release to the air

around the cylinder and head. Carbon on the underside of the piston can make problems,

too, especially when combined with other shortcomings. Needless to say, poor base compression

is detrimental to high power output and slow speed because 2-cycle operation is all due

to pressure differentials and if seriously upset, gives you problems. Don't misunderstand

us ... an engine does not have to be new. As a matter of fact, some sloppy engines work

well. Remember the loose engine that screams at the top and ticks over smoothly at the

bottom? It may feel loose when flipped, but it seals well when running.

The next few paragraphs will discuss how design factors in engines can cause changes

in power and idle in our power plants, and why various factors alter their performance.

The ideal compression ratio for multi speed work, lies somewhere between 6 and 8 to

1, depending on the make. Compression ratios above 9 to 1 are detrimental to idle and

lowering will definitely improve it, but this can be overdone as reductions below 6 to

1, while they do give a small additional gain, seriously reduce maximum power.

Crankcase compression ratio is satisfactory on current radio control engines and is

not particularly critical in the performance areas around which our present engines are

designed. However, if we suffer poor base compression, due to leakage at low R.P.M.,

our idle suffers as there is a loss of velocity at the throttle due to reduced suction,

and insufficient pressure to properly boost the mixture into the cylinder. Also, in some

cases, fluctuating low base compression can cause uneven draw at the throttle during

intake. An interesting sidelight here is that modelers have experimented in speed control

by varying crankcase compression through a variable leak, but to date, this has been

unsuccessful.

Shaft intake and exhaust port timing can be altered to make an engine idle beautifully,

but a generous amount of top R.P.M. will be sacrificed and this, of course, is not good.

In the engines tested, the intake timing ran anywhere from 185° to 210°, and in one instance,

220°. Almost all of them close at 45° after dead center. The closure point has much more

significance than the opening point. What you look for here at low speed is that the

shaft not be open for too long a period after the piston starts down, because crankcase

compression will force mixture back out the intake. I'm certain most people have observed

this condition in a small way when an engine is idling.

Two of the many R/C models used by H.T. Harv

reports "final" clothes-reel test rig was destroyed when a Veco 45 accidentally jumped

into wide open speed ("unbalanced reels at high rpm are unstable!").

At real high speed, late closure timing increases power because fuel and air have

inertia, and will continue to pass into the crankcase though there may be a small amount

of counter-compression building up in the case. This is another way of saying that the

engine has passed the peak in the troque curve resulting in a reduction of Volumetric

efficiency. For those of you who care to experiment, try closing the shaft timing between

25° and 35° for a pleasant surprise ... but watch the drop in maximum R.P.M.!

Heat dissipation or thermal balance is a hard nut to crack as fuel, glow plug, cooling

and basic materials all tie together. Best success usually comes with the cylinder head

operating at a maximum of 400° F. after the engine has been running at top R.P.M. for

at least five minutes. This should be followed by two or three minutes of idling after

which the head temperature should stabilize at 220° or so thereabouts. As you can imagine,

this is a somewhat difficult problem due to the fact that you never get the fuel, humidity

and temperature conditions ideal.

Fuels are a book in themselves, to discuss them without consideration of the glow

plug would be foolish, so we will try to tie them together as we go along.

Mixtures containing between 5 % to 10% nitromethane with 25% castor oil give us a

good balance of power, smooth running and idle. In some engines, castor oil content can

be lowered to 20%, but I would not recommend anything below that. Additional nitro does

not destroy idle as some are prone to believe. Hot fuel does not raise the engine temperature

at idle since nitro does not bum at a higher temperature. At top speed nitro increases

power by liberating more oxygen, not increasing 'temperature. Your engine does run hotter

at higher speeds because it is developing more power (burning more B.T.U.'s) and will

not pass heat through the fins at a proportionally higher rate than when running slow.

Elimination of nitromethane does not affect engine performance other than to reduce top

speeds.

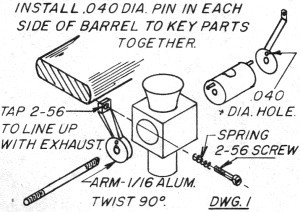

Carburetor drawing 1.

Carburetor drawing 2.

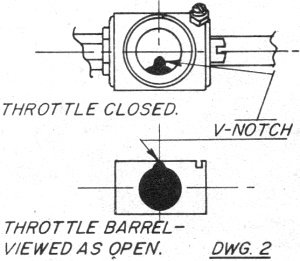

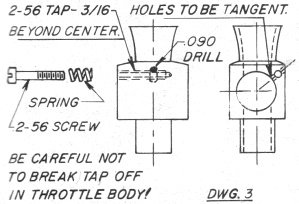

Carburetor drawing 3.

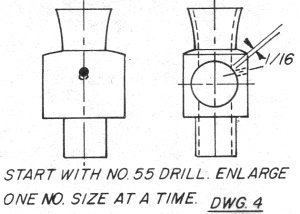

Carburetor drawing 4.

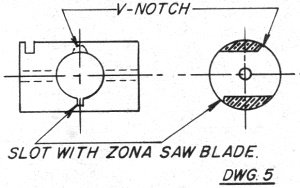

Carburetor drawing 5.

One thing to watch if you make a drastic change in the nitro content ... check idle

performance before flying. Once a carburetor is tuned to a fuel with a specific amount

of nitro, you should stick to that fuel inasmuch as nitro needs three to four times as

much air as does methanol. Any drastic change in nitro means that the filed notch or

idle air bleed in the throttle should be altered... that is to say, as more nitro is

added, more air is needed. Just watch the filing, because if too much is removed, throttle

suction is reduced to the point where idle is not dependable. A little side-light on

nitromethane: it is a double edged sword because while it lowers the flash point, which

in some instances helps idling a mite, it also advances timing which can cause pre-ignition

and detonation when your mill is running flat out.

As stated previously, the glow plug is almost married to the fuel. To make a quick,

simple suggestion, we recommend a mild fuel (0% to 10% nitro) with a hot plug. The plug

should not be hot enough to cause pre-ignition and/or detonation as a run in this condition

can do your engine harm. We stick to one fuel the year round (K & B 100), and adjust

for temperature with just 2 glow plugs, a cold one for hot weather and a hot plug for

cooler temperatures. This combination takes care of us from 0° to 120° F. Changes in

humidity do not alter low speed characteristics seriously, but may show a change at top

R.P.M.

With regard to the relationship between so called hot fuels and the heat ranges of

glow plugs, there is currently no definition of a hot fuel which is entirely acceptable

to the glow plug manufacturers and it is inadequate to simply categorize a glow plug

as being hot or cold. We normally think of a long plug as being hot and a short reach

plug, cold, but this assumption is rather general since plug materials, coil shapes,

coil diameter, wire diameter, wire size and length, idle bar, all contribute to heat

range determination.

Actually, a plug should be classified as to its ultimate effect on the engine; We

have proven to ourselves that an idle bar definitely assists idle, especially in colder

situations. Wire type and diameter, as noted in relation to heat ranges, have a decided

effect on deter-mining a good idling glow plug. As you may remember, the old A.C. plug

had a small cavity opening at the bottom which somewhat protected the upper coils of

the element from fuel spray, but the biggest improvements in plugs are the cross bar

or idle bar, and the longer and heavier element.

The cross or idle bar helps retain the heat so necessary to keep a plug operating

- when it is being drowned out with a rich fuel mixture. The idle bar's pri-mary function

is to retain heat in the coil as the incoming mixture hits it. Secondly, it helps somewhat

to keep spray out of the plug. On this basis, it could be contended that the larger the

idle bar, the better. However, in going to these larger diameter bars, the point could

be reached where possibly no fuel could touch the coils. Therefore, the engine probably

would not run since fuel has to bum to start the combustion chain.

While location of the glow plug in the cylinder has some effect on idle, where to

place it is the sixty-four dollar question. Hours of experimentation revealed nothing

conclusive and if we read correctly between the lines in letters from manufacturers,

they don't know much more than the rest of us.

For those of you who want more basic information on plugs-the whys, wherefores, design

and operation - take a look at the September 1960 American Modeler where Bill Netzeband

presented a comprehensive run down on the glow plugs, their heat ranges, and some of

the mysteries associated with them. I don't completely concur with everything Bill says;

but on numerous points I am in accord. Actually, Netzeband's article is a bit of a classic

since no one previously has tied heat range and fuels together. Considering the various

charts and graphs he made up, we suspect that he went much deeper into some of the mysteries

of plugs than even some manufacturers who have made them."

As far as preferences in multi-speed engines go, we hesitate to specify any in particular

since many reliable ones are available. We do prefer those in which the crankcase and

cylinder housing are cast in one piece and has an inserted steel liner. Our experience

shows that ball bearing engines are not mandatory in R/C since a properly fitted sleeve

bearing has little more friction when running fast than balls. Two reasons why ball bearings

have a small advantage: at idle, the ball bearings do have less friction, promoting smoother

operation, secondly, ball bearing engines with their greater mass, due to bearings and

larger castings, help damp out vibration.

Concerning throttles, this runs the gamut and we have tried choke throttles, carburetor

throttles, exhaust dampers, (damper, not baffle, is the correct nomenclature) and crankcase

bleeds. We hooked a nickel-cad battery to the plug which helps in some cold situations,

but under normal conditions this is not necessary and merely indicates that the trouble

lies elsewhere.

Generally speaking, throttles fitted to production engines nowadays are quite adequate

for the job... but due to variables in individual engines which come off the line, quite

often a bit of doctoring of one sort or another is required.

Our experiments indicated that throttle type can relate to engine size... for which

we can find no reason. But as an example, small engines idle more reliably with exhaust

dampers (no intake throttle) than the big inchers. It indicates that the intake throttle

becomes more necessary as displacement goes up. While a choke-type intake throttle works

well on small engines (.15 disp.), larger engines show an improvement at idle when this

type is replaced with a carburetor throttle.

Curiously enough, exhaust throttle design has an effect on engine idle performance,

too. We found that the drum-type exhaust damper worked a bit better than the sliding

vane or railroad signal variety, and this, incidentally, is the style used on the Veco-Lee

45. This damper is a rod with its center portion cut away so that there remains a thin

web which shuts off the exhaust when vertical and opens when the web is rotated horizontally.

It seems the closer this device is located to the cylinder sleeve, the better your engine

will idle. We can furnish no explanation for this and queries to several manufacturers

confirmed this - they could offer no reason why. In conclusion, we recommend that for

good idle, an engine be equipped with both an intake throttle and exhaust damper.

If you own an engine whose idle is unsatisfactory, we will outline the steps to take

in determining what is wrong and how to rectify it.

As mentioned in the beginning, check your engine over closely to see that it is in

good shape. Next, select a good fuel that gives adequate power and has inhibitors which

retard formation of gum. Assuming you have a good engine and fuel, we now have the glow

plug, intake throttle, and exhaust damper to work around. First, almost all engines which

come equipped with intake throttles have some sort of idle stop or adjustment for the

throttle barrel. For those engines which do not, and those of you who want to adapt a

carburetor to an existing engine, Dwg. # 2 shows the installation of a stop and a means

of securing the parts on a Bramco throttle.

Our next step is to mount your engine on a test block with the same type of tank to

be used in the airplane, in the same position. This part of the sequence can be conducted

in the airplane, but having the engine in the open makes working on it considerably easier,

especially if the throttle barrel has to be removed.

Fill your tank a little over half full and run the engine wide open. Get her up to

a screaming two-cycle and and then .back the needle valve off some to run it slightly

rich. This is your needle valve setting to be used in adjusting the throttle so don't

change it. Now we select a glow plug. Start with a hot plug and run wide open to determine

if the engine crackles. If it crackles the slightest bit, go to a cooler plug, because

sure as shootin' if you leave the hot plug in, the engine will crackle on that hot day

when she is under a load in the air. Our objective is to use as hot a plug as possible

with no sign of detonation - something that can make a wreck of your engine eventually.

At this point, we start work on idle by altering the intake throttle if necessary.

Bleeding of additional air into the engine is necessary at idle or else the engine would

cut out very shortly due to a grossly over-rich mixture. This is done in one of three

fashions: (1) File a notch on the top side of the throttle barrel as appears on K&B

and Veco engines - Dwg # 2; (2) Drill an idle air bleed hole in the front of the carburetor

body in the location shown, such as done by Harold deBolt - Dwg. #3; (3) Make a screw

adjustable idle air bleed as used on O.S. Max and Merco engines - (Dwg. #4).

Once you have decided on one of these systems, or if it is already provided, idling

tests can commence. In the following, we will refer to filing the V-notch and the operation

is analogous to the other two, drilling the hole larger or opening up the bleed screw.

In the deBolt system, start with a #55 drill and proceed one drill size at a time.

Take off the exhaust damper or disconnect it and wire it wide open. Start your engine

and slowly retard the idle. If it begins to rich en up and quit, remove the throttle

barrel and increase bleed area by filing the idle notch deeper and wider with Swiss pattern

files - take a few swipes at a time. Start the engine up again and repeat the following

procedure, filing a bit at a time - do a neat job-file symmetrically and watch the file

so that metal is not removed on the opposite side of the barrel. Repeat the procedure

as many times as necessary until the engine idles fairly well at between 2,800 and 3,300

R.P.M. Do not judge R.P.M. at this point by ear as it is very deceiving with the throttle

damper removed. In our tests, we had one of the new General Radio Strobotacs which a

local company loaned us. Use a tachometer of some sort. If using a reed type tachometer

(Vibra-Tak) try to have it checked somewhere first. Accuracy at lower ranges should be

within 200 R.P.M. of a known standard.

Back to the battle. While the engine is idling fairly well at the aforementioned speed,

accelerate it and decelerate it. It is not necessary to do this any faster than a servo

does, not instantaneously anyway. Chances are the engine will decelerate okay, but may

quit on acceleration while tossing off some smoke from the exhaust. This is an indication

that the engine is loading up on idle so make the V-notch a bit larger and continue until

the engine goes up and down fairly well. During this operation, do not touch the needle

valve as set for full power on the rich side. Also do not make any attempt to get lower

than 2,500 R.P.M. or the plug will probably cool off. Also, if you keep filing past the

point where the engine idles well, it will die out due to lack of fuel suction and this

is remedied by filing a very small V-notch (1/32" deep) 180° degrees from the first one,

on the opposite side, to increase suction at the throttle and richen the mixture.

Bolt on or connect the exhaust damper and idle your engine again. Generally, you will

experience an additional 200 to 300 R.P.M. drop. If the engine strangles to a stop, the

damper is fitted too tight and prevents some exhaust leakage which is remedied by opening

the damper a hair or otherwise fitting it looser. Conversely, if the engine R.P.M. does

rise, then tighten up on the exhaust damper to cut down leakage.

"Idling Secrets" will be concluded in December issue of American Modeler

* The editors advise us that this valuable report will be presented

in updated form in the forthcoming American Modeler ANNUAL for 1963 which goes on sale

November 15.

Articles About Engines and Motors for Model Airplanes, Boats, and Cars:

Posted December 17, 2011

|