|

During

World War II, a lot of leisure activities were sacrificed due

to unavailability of raw materials for manufacturing products needed

to pursue them. We have all see photos of kids collecting scraps

of metal, rubber, and other materials for recycling as components

of airplanes, guns, canteens, ships, etc. Aircraft modeling took

a hit along with most other hobbies since metal for engines and

wood for airplane kits (balsa was popular for shipping contain packing)

were scarce. It wasn't until the late 1940s that Roy Cox was able

to begin mass producing his famous line of miniature engines, most

notably the .049 family. Other manufacturers - like Allyn - were

following suit. This article reviewing the Allyn .049 Sky Fury came

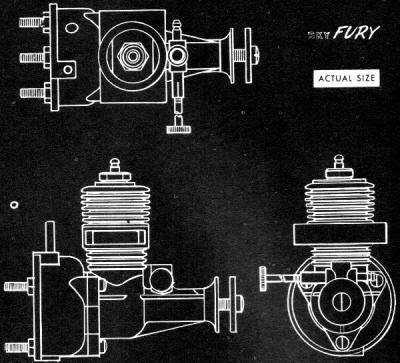

in 1954. Allyn .049 Sky Fury Engine Review

Allyn .049 Sky Fury reveals new, important improvements, runs steady,

wide rpm range. By E. C. Martin

The design of the Sky Fury affords big-prop, high-torque performance

as well; good for free flight. |

A novel and most interesting engine, the Sky Fury is a refreshing

departure from conventional Half-A design in almost every detail,

and justifies its difference with a sparkling performance. The Allyn

engineers have obviously tossed convention out of the window and

made a fresh start, with a result that embodies several functional

improvements which are doubly attractive because they also simplify

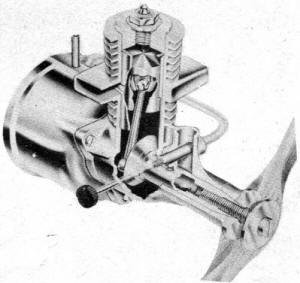

production methods. The basis of the Sky Fury is a neat

aluminum pressure die casting which incorporates intake, main bearing,

crankcase, the entire cylinder including head and fins, and large

double opposed exhaust stacks. Three equally spaced radial mounting

lugs of a full 1/8 in. thickness do much to eliminate the broken

lug bug, and the absence of a cylinder flange thread takes most

of the risk out of a careless plug change, whereas the widely used

screwed cylinder assembly is prone to distortion when tightening

of the plug or cylinder is not carefully done. The cylinder

barrel is accurately bored to a close slip fit for a drop-in type

cylinder liner, and a shoulder at the bottom provides end location

in one direction, while a plug screwed into threads at the top of

the bore constrain it in the other, thus sandwiching the liner in

a manner which directs all stress axially along the cylinder walls.

In this way, all the bore distortion from radial thread loading

common to normal screwed assemblies is removed. A short

and rather small diameter crankshaft rotary intake provides unusual

flexibility and potent fuel suction, but somewhat restricts top

end performance. Several other design features tie in with this

carburetion characteristic to provide a great deal more torque than

usual among Half-A glow engines which are almost exclusively in

the high bhp at high rpm category, and the resulting big prop performance

combined with usefully dimensioned exhaust stacks, long jet needle

and single vent large capacity tank, makes the Sky Fury of interest

to free flight scale enthusiasts. Viewed in this light, a slightly

longer intake would probably improve carburetion still further,

and greatly facilitate handling and the attachment of an extension

for cowled installations.

A

nickel plated brass spray bar, with a split female thread frictioning

device, is press fitted into substantial bosses on either side of

the intake, and the delivery side has a bore that is smaller than

the maximum diameter of the needle taper so that a positive fuel

shut-off is available if required. A

nickel plated brass spray bar, with a split female thread frictioning

device, is press fitted into substantial bosses on either side of

the intake, and the delivery side has a bore that is smaller than

the maximum diameter of the needle taper so that a positive fuel

shut-off is available if required. Every effort has been

made to reduce crankcase Volume and charging loss to a minimum.

The bearing end of the crankcase is accordingly hemispherically

shaped with a small annular projection to sustain the thrust loading

of the crank disc, and the disc itself is heavily chamfered to suit,

and also to clear the overlap of the piston at bottom dead center.

The two alternative backplates supplied are arranged to butt up

as close to the crankpin as possible and are stepped for piston

skirt clearance. Aluminum pressure die castings of substantial

proportions comprise the combined backplate and radial tank mount,

and alternative regular backplate, both being formed to match the

crankcase mounting lugs. The tank blends into a bell shape in order

to provide a mounting face of large area, and to accommodate a large

fuel supply without excessive overhang. Only one vent tube is fitted

and this extends down into the tank in such a way that fuel level

when filled is only slightly above the jet with the engine in a

horizontal position. A boss is cast into the bottom of the tank,

however, which can be easily drilled for a lower vent tube, and

the existing upper tube can be replaced by one of appropriate length

to produce a simple stunt tank. The plastic delivery pipe extends

through the usual hole in the top to the tank bottom, and owing

to the lack of a second vent it is wise to use the delivery pipe

for filling if carburetor flooding is to be avoided. Three mounting

bolts are supplied which also serve to retain the tank and tank

backplate. Vellumoid gaskets are used at both joints. The

case hardened steel crankshaft is of average dimensions for the

displacement, having 7/32 in. outside diameter, 5/32 in. dia. gas

passage, and 1/8 in. dia. crankpin. A circular valve port of 5/32

in. dia. is used, which is ample for the size of air intake. Apart

from a most excellent surface finish, the crankshaft is interesting

because it is hollow through its entire length, and the prop retaining

bolt is the only agency which opposes crankcase leakage. In practice

there is slight oil seepage of no consequence, apart from which

the system seems very satisfactory. The payoff on this feature goes

to the man and machine that tap the hole. It is considerably quicker

to tap than the usual blind variety. A fairly abrupt taper provides

keying action for the aluminum prop driver and an aluminum washer

and blued steel bolt retain the special 6 x 3 Sky Fury (Top Elite

manufactured) prop supplied. A machined aluminum conrod

with ball jointed small end and outstanding crankpin fit and finish

is retained on a recessed boss inside the hardened steel piston

by a cup which is swaged over rod and boss to form a permanent assembly.

The

piston skirt is about 30 percent longer than usual for the displacement,

and as a result, exceptional life may be expected from both piston

and cylinder, as loading is distributed over a larger area and better

guidance reduces piston rock. However, we seldom get something for

nothing, and the above benefits are offset, to some extent, by the

necessarily longer cylinder and the increased total crankcase Volume

arising from the greater internal Volume of the piston. This is

actually a limiting factor for ultimate performance which has already

been prevented by the intake and shaft valve, so in the final reckoning

the piston dimensions may be taken as an asset, as it is under heavily

loaded conditions that the Sky Fury excels. The Meehanite

cylinder liner is extremely interesting as it employs a bypass porting

system that is unique in this country, while paradoxically being

almost universal among European engines. It takes the form of four

grooves which appear to be holes with an imaginary center inside

the bore diameter, which is indeed exactly how they are made. A

plug is inserted in the bore, during manufacture, which has four

holes in it that break out of its outside diameter. An end mill

inserted in each hole then chews a crescent shaped groove out of

the cylinder wall to a depth corresponding to the height of a normal

bypass port. The final result is a port and bypass passage produced

in one machining operation. The piston, of course, provides the

inside wall of the passage. The advantages are smooth gas flow and

excellent piston lubrication, while the disadvantages devolve on

the manufacturer in the form of worn or broken end mills and bore

honing difficulties. The cylinder wall has to be slightly

thicker and heavier than usual to accommodate the grooves, but,

as a result, has a resistance to distortion and heat conducting

quality that would be an asset to most of the conventional designs.

Two opposed exhaust ports, each covering about 160°

of the bore circumference, are located just above the bypass grooves

to provide valve events of typical nature for a radial ported engine.

Piston crown and combustion chamber, however, have flat faces, which,

contrary to expectations, did not seem to produce excessive charge

loss or dirty exhaust. The head, as already mentioned, is

an aluminum plug which screws into the main casting to bear on the

top lip of the cylinder liner, with a plasticized gasket between,

and has a pair of small flats projecting about 1/16 in. above the

casting for wrench application. An interesting glow plug

is supplied. It has a very large Volume recess and an element in

the form of a "W" pointing downward. During the test, conventional

plugs were substituted and it was found that few gave such good

results at any speed and none at very low speed, where a point could

be found at which no other would sustain running unless the battery

was connected. It was also apparent on the test that the

Sky Fury has remarkable range of speeds over which it will run steadily.

A sticking tendency between piston and cylinder may be in

evidence in a brand new engine. This is a common peculiarity of

the materials used and will disappear eventually. It has no effect

on performance and occurs only during hand cranking. Test:

Allyn Sky Fury .049 Plug: 1/4 x 32, Short reach as supplied,

1-1/2 volts to start; Fuel: O & R AA; Running Time Prior to

Test: 2 hours; Bore: .390 in.; Stroke: .400 in.; Weight: 1-3/4 oz.

Power Prop

RPM

6 x 5

10,000

6 x 4

11,000

6 x 3

12,900

5 1/4 x 5

12,200

5 1/4 x 4

13,200

5 1/4 x 3

14,300

Top Flite

RPM

6 x 5

9,500

6 x 4

10,700

6 x 3

12,000 Sky Fury prop supplied

12,400

Articles About Engines and Motors for Model Airplanes, Boats, and Cars:

Posted March 1, 2014

|