|

Re-timing, cleaning up (air

and fuel flow passages), freeing up (sliding friction), lightening and balancing

(removing unnecessary material),

and breaking in (initial running with rich fuel mixture while interfacing metal

parts fit themselves to each other) are all part of the effort necessary to create winning engines for

model racing events. This 1962 American Modeler magazine article predates

Schnuerle porting (in model engines), ABC (aluminum, brass, chromium) cylinder liners,

and modern metal alloys, but still the concepts are applicable to today's engines.

It purpose is to instruct on proper engine break-in so that it will have a long

lifespan.

Wankel lovers will appreciate the homemade engine shown.

Hot Engines!

This has become one of the traditions of annual air-model National

championships: motor repair service operated by K&B. John Brodbeck (left) and

Bill Wisniewski try to figure how contestants can beat 'em up so.

Larrv Conover and Warren Kurth join forces to bring you this vital series; Part

2 next issue!

This report on speed and engine re-work is designed to give a comprehensive insight

into the methods and general approach used by experts in our various gas powered

events. This includes both control-line and free-flight power.

Perhaps the most important information we can pass on is the use of a scientific

method for improving the performance of your models. We will refer to the measurement

and recording of rpm readings throughout the text. The results you derive from "re-working"

depends on your ability to accurately measure changes in engine HP. The best

way is with the use of a good tachometer. So tachs are covered in this article.

Yes, you may be wondering why the engine manufacturer, with all his professional

know-how, can't put an engine on the market with ultimate performance built into

it. First of all, if it is to sell to the mass market it must operate easily and

efficiently over a variety of speeds and loads. By contrast., the hopped up speed

engine is tuned to operate at one specific high rpm while drinking large quantities

of expensive highly nitrated fuels. The modifications may also make it harder starting

and critical to operate. If it is run at a lower rpm its power will drop off rapidly.

Second reason is the limiting factor of economical production. The manufacturer

can not afford extensive hand work, or special materials (example: precision ball

bearings) if he is to keep the cost of his product within reach of the average modeler.

Engine rework can be classified under three main headings: RE-TIMING, CLEANING-UP,

and FREEING-UP. The last two terms are overworked catch-alls, but they do include

some basic methods and operations, so we explain them in general.

Re-Timing

The trend is to engines which turn faster on smaller props, and develop peak

HP at high rpm. Many engines can have their rotary valve timing modified to give

better performance in the 20,000 to 25,000 rpm range. Usually, opening the.

rotary valve port so that the intake closes later in the cycle will help. In fewer

instances, opening the valve port to let the intake open earlier may help, too.

But remember, the exact timing to be used is dependent upon several factors: Peculiarities

of the engine, its compression ratio, rpm at which it is expected to run, diameter

and length of venturi, bore-stroke ratio. All these factors are interdependent,

a change in one will nave an effect on the rest.

For example: Generally the rotary valve is still open for 40 to 60 degrees after

the piston has started its downward motion, building up crankcase pressure, and

tending to force the fresh charge of fuel vapor back out the venturi, However, the

momentum of the incoming fuel charge, due to its velocity build-up in the venturi,

will continue to carry fuel into the engine despite back pressure being developed

by the descending piston, As rpm increase, .this fuel charge velocity and momentum

builds up, therefore we can change the timing and leave the valve open a wee bit

longer.

Another thing we can do if we are going to run only at high rpm is to change

the cylinder port timing. Top edge of intake port may be filed ,upward to let the

port open earlier. Again, depending on the particular engine, the exhaust port may

be filed upward a greater or lesser amount than the intake port.

Height of piston baffle or dome will have some effect on timing. Filing down

the top of the baffle, or leveling it off on the intake side helps with some engines.

An interesting extreme is the Italian Super Tigre 15 which has no baffle on top

of a flat piston, while the intake and exhaust ports in the cylinder open almost

simultaneously.

"Cleaning-Up"

This is a term used to define all the modifications which make for easier passage

of the fuel mixture from the venturi opening to the combustion chamber. Most obvious

suggestion is to polish all surfaces over which the fuel mixture must flow, and

to radius and streamline all edges over which the mixture passes. Polishing thus

includes the connecting rod, crankshaft counterbalance, crankcase, bypass, and the

inside of the crankshaft - if the engine has a front rotary valve. The lower outside

edge of the cylinder intake port can be streamlined. Also the lower end of the bypass,

the edges of the connecting rod if it has a rectangular cross-section, and - if

a front rotary valve - the rear opening of the fuel passage. On some front rotary

engines, the venturi opening and crankshaft port opening may be lengthened and squared

out to match each other. Rear edge of shaft port can be radiused (details later)

and if shaft-port has been put in by milling flat across shaft, excess material

may be ground away. But be careful throughout all these operations that you don't

accidentally grind past the edge of the port and change the timing.

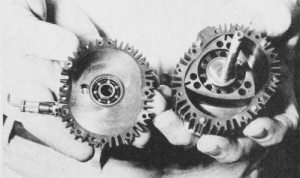

Remarkable engineering feat 2 years in development: revising

Wankel "pistonless" internal combustion engine for 2-cycle running. Floyd Nell,

St. Louis, did it: .50 c.i.d.; 10,000-rpm; all steel; ball & needle bearings;

20-oz.

On some engines it helps to open out the throat of the venturi, but opening it

too much can give negative results. The optimum venturi size will vary with different

engine set-ups (rpm, timing, engine layout) so here again, investigate before you

operate.

If your engine has a front rotary valve and uses a rear crankcase cover, round

off the cover so that it does not obstruct the lower end of the cylinder bypass.

In general, the foregoing operations which comprise "cleaning-up" an engine will

produce the least gain per time expended in re-working and are of lesser importance

than the re-timing of "freeing" modifications.

One other point worth mentioning here is compression ratio - both cylinder compression

and base compression. The cylinder compression ratio may be varied for better performance,

but the governing factor will be the fuel you will be using and to some extent the

glow plug and cylinder timing. Most of the racing engines now have compression ratios

pretty well on the high side as they come from the factory. An old trick, especially

with the various McCoy engines, was to increase the base compression or "pack the

crankcase" by various means such as thinning down the connecting rod and shortening

the crankpin, which allowed facing off the crankcase to reduce Volume. The lightening

holes in the rotor disc were plugged with balsa also to reduce the crankcase Volume.

Such methods which worked well at lower speeds generally are not satisfactory at

today's high rpms.

"Freeing-Up"

This includes all the methods used to decrease mechanical friction in the

engine so that the greatest percentage possible of the energy released in the combustion

chamber can be transformed into useful horsepower at the propeller.

First step is cleanliness. This is extremely important. .Any re-working of parts

should be finished off with crocus and oil (or jeweler's rouge and oil) to remove

any trace of roughness. Then after any polishing or lapping, the parts involved

must be thoroughly scrubbed with a small stiff brush in hot soapy water. It is imperative

that every trace of foreign matter be dislodged from the pores of the metal or the

engine will soon grind itself to a worthless mess. Many a good engine has been ruined

at this point by a too-hurried cleaning.

Some engines as they come from the factory have the piston-cylinder fit set up

just a little too tight for high speed running. It is advantageous to lap these

out a little with jeweler's rouge or a fine grade of rubbing compound. It will take

some experience, or the advice of an expert on that particular engine to know how

much to lap. The engine must not be lapped out so much that it loses its compression.

Generally, as our operating rpm goes higher, we can stand a little more compression

loss for the sake of a free fit. Also, some engines benefit from a fine polishing

of all the wearing surfaces before they are even broken in.

The diametric clearance between the crankshaft and its bearing, on a plain bearing

engine, is important for free running at high rpm. Usually .001" for a 1/2A and

.002" for larger engines is the minimum acceptable - although in some cases, double

this amount of clearance will improve performance.

The bearing of a ball bearing engine should feel absolutely free of any tight

spots or roughness. So be careful to always keep bearings free from dirt, and so

not touch the ball races themselves. Perspiration from the fingers will ruin them.

A few drops of light oil after each day's running will help keep moisture from collecting

on the bearings.

Some modelers replace the ball bearings in their engines with high speed precision

bearings, but there is a catch here. The running clearance of a high speed bearing

is just as important, if not more so, than its precision for this clearance determines

the actual sliding friction and the loads imposed on the balls when the engine is

running. A precision bearing with the wrong internal clearance may do more harm

than good. Along this same line, the shaft fit in the bearing is very important.

So it's best to consult the bearing manufacturer for your particular application.

Port hooking is another robber of power. This is caused by the side loads which

result in slight tipping of the piston in the cylinder. What happens is that the

top lip of the piston catches on the top of the cylinder ports as it travels past.

A very slight radius or chamfer put on the piston lip and on the inside edges of

the cylinder ports will alleviate this. Some engines have this already done when

they come from the factory. Go very easy when doing any work inside the cylinder.

Any re-working which reduces the the strength of the part involved should be

held to a minimum. The more we reduce the strength of any part, the more it distorts

under load, causing binds and friction. And the net result may be a power loss instead

of a gain. This is a very important point to weigh when considering any reworking.

Turning down of cylinder fins is generally best avoided. Certain internal stresses

are set up in the metal of the cylinder when it is machined. When the outside fins

are turned down after the manufacturer has honed the cylinder to shape, some stresses

are released, which may disturb the balance and warp the cylinder.

When all the re-working has been done, the engine should be assembled carefully,

tightening all screws slowly and evenly, while checking for any binds in the engine.

If any binds are felt, the cause must be found and corrected before the engine is

run.

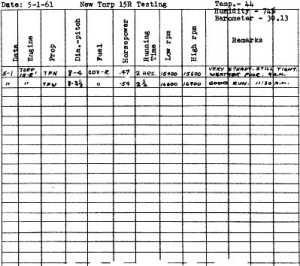

Here's how a dedicated researcher records his data on engine

performance; accurate measuring devices are absolute "must."

Breaking-In

This should be accomplished in a series of short one minute runs at high speed,

using a speed fuel that has plenty of oil in it. The reason for the short runs is

twofold - to prevent heating and to let the engine break in quicker on less running

time. The number of heating up and cooling off cycles is a factor in break-in. It

is best to break-in an engine at approximately the same speed that it will be run

in the air. The wear pattern on the moving and bearing surfaces changes with rpm

because the inertia forces of the reciprocating parts increase and the effective

pressure in the cylinder decreases with increasing rpm. By holding to one approximate

rpm throughout the life of the engine we have a better chance of keeping a nice

smooth wear pattern. Take for instance a plain crankshaft bearing which tends to

become oval as it wears. If we run it at various speeds it will, instead, assume

a rough clover leaf shape which produces extra friction and vibration.

Also at higher rpms there is less chance for shellac deposits to form on the

cylinder walls. This deposit, often referred to as engine varnish, usually occurs

with a new engine which is tight. A combination of tight fits, damp weather, and

fuel ingredients cause it to form. You spot it first when the rpm starts to sag

and the engine heats up abnormally. The engine loses it free feeling at the top

of the stroke (plug out). You can see it on the cylinder looking through the exhaust

port ... a sort of brownish film. It may be a little hard to recognize the first

time, but when you clean it off you will see the difference. There is no choice.

You have to remove it. Remove the cylinder and clean it with fine grade steel wool.

Molybdenum disulphide is an additive which should be used during break-in, either

in the form of a sub-micron powder which can be mixed directly in the break-in fuel,

or as an oil base suspension. Molyfilm, an oil suspension, has become the most popular

form of molybdenum disulfide with the speed fans. It is classified as a solid lubricant,

a slippery powder that has an affinity for soaking into the pores of the metal and

makes a thin film as little as one-millionth of an inch thick. This prevents metal-to-metal

contact and reduces the tendency for galling and seizure. The result is a reduction

in running time needed for parts to mate properly, and a reduction in engine wear

during break-in.

To check for a free fit, take out the glow plug and loosen the rear crankcase

cover of your engine. Oil it with a light oil and turn the shaft till the piston

is at the top of the cylinder. If your engine has been "freed" properly, the piston

will return to bottom dead center of its own weight. (Ringed piston engines excepted,

of course.)

Assuming that your engine has the basic layout and timing needed for speed work,

this business of "freeing-up" will have more to do with your engine output than

any other factor.

Lightening and Balancing

We might consider briefly this additional type of modification. So far very little

has been accomplished in this area, and then only via extensive experimenting. By

removing some weight from the reciprocating parts-piston, connecting rod, and wrist

pin - we reduce the inertia forces which the motor must overcome when it changes

direction twice every revolution. The net result is faster acceleration of the piston

during each stroke, and lighter loads on the bearings. However, there is usually

not a great deal for us to do here, since we encounter problems of distortion and

resultant binding when too much metal is removed. Also, the manufacturers have improved

this feature steadily over the years.

Balancing is another problem. Since the inertia forces caused by the reciprocating

parts vary with different rpms, it is impossible for an engine to be perfectly balanced

at all speeds. Therefore, it becomes a problem of balancing the system for the specific

rpm you wish to operate at. Unless you have a bad vibration problem it is best to

leave this balance set up as designed. If you do have excessive vibration you should

first check for unbalanced props, poor motor mounting, or a bent shaft.

So there you have the basic ingredients of a hop-up job. If you would like more

detailed recipes for your particular engine, go to contests and talk with some of

the experts. There have been some helpful hop-up ,articles in the past.

Dynamic Models Inc., 13755 Saticoy Street, Van Nuys, Calif., has published some

very good information on this subject in their "Tech Tips" ... their issue # 6 deals

specifically with reworking engines. Obtain same by writing to the company.

Posted February 5, 2023

(updated from original

post on 7/7/2012)

Articles About Engines and Motors for Model Airplanes, Boats, and Cars:

|