|

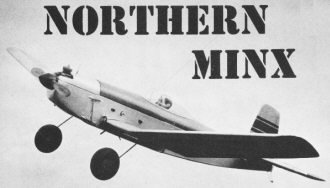

In 1956 when this Northern Minx

article and plans appeared in Young Men magazine, state of the art

radio control (R/C) was still composed of vacuum tubes and discrete components,

usually connected together via point-to-point wiring. Batteries were of the

lead-acid type for the transmitter and carbon or alkaline for the airborne

receiver. As you might guess, that resulted in heavy models which needed to be

relatively large in order to keep the wing loading down. Northern Minx only had

a 48-inch wingspan, and used a simple one-tube receiver with a rubber-powered

escapement for channel control of both the rudder and the elevator. The plans

show only the rudder control installation, and the photos appear to only show a

single escapement, though. The builder just about needed to use a shoe horn to

squeeze all that in the fuselage. Interestingly, the Northern Minx has a

break-away nose section containing the firewall, engine, fuel tank, propeller,

spinner, and cowling. Rubber bands holds it to the front of the plane. The

Jodel-style wing is of

polyhedral configuration.

Northern Minx

By Jack S. Luck By Jack S. Luck

Canada's top designer gives you this proven radio model: 4' span; for .09 to

.15 power

An efficient design for the more advanced builder, our Minx is not for those

who have been spared past experiences in really "building" model planes. There are

no promised short cuts nor implied assurance that it can be put together with an

old razor blade and 35 minutes of spare time. This is a project. The only promise

is that if the Minx is constructed with reasonable model-engineering precision it

will be a joy to build, and an even greater joy to fly.

Specifications and features: 4 ft. span;

380 sq. in. wing area; .09 to .15 cu. in. displacement motor; unobstructed access to R/C

gear; knock-off nose assembly; torsion-sprung landing gear; vibration free fuselage. Specifications and features: 4 ft. span;

380 sq. in. wing area; .09 to .15 cu. in. displacement motor; unobstructed access to R/C

gear; knock-off nose assembly; torsion-sprung landing gear; vibration free fuselage.

Minx as here described is the second in its line. The prototype underwent several

modifications before a satisfactory balance of variables was achieved. As all the

modifications were concerned with force arrangement as affected by both moments

and angles of attack, the final version used all the components of the prototype

except the lower half of the fuselage. Greatest single departure from the original

design was lengthening the tail moment. Result is a ship which is lively without

being overly critical. Its short-coupled prototype had been very "nervous" and sensitive

to a point where a shade too much down or side thrust meant a very hard landing

indeed; so violent and untidy at times that it seemed hopeless to expect anything

less than a total creaming. Because nothing ever happened that couldn't be fixed

in a few minutes, even after the most shattering impact, it seemed conclusive that

the structure was soundly designed.

Construction is elementary. Fuselage crutch

is pinned down flat and square with the former FF just over the edge of the board.

Entire structure except for wing saddle and the 1/8" sheet filler between formers

FF and 3 is completed and sheeted before it is removed from the board. Setting the

wing at zero incidence, the saddle is cut to exact contour after the wing center-section,

except for the fairing, is complete. Fuselage is then finished. Construction is elementary. Fuselage crutch

is pinned down flat and square with the former FF just over the edge of the board.

Entire structure except for wing saddle and the 1/8" sheet filler between formers

FF and 3 is completed and sheeted before it is removed from the board. Setting the

wing at zero incidence, the saddle is cut to exact contour after the wing center-section,

except for the fairing, is complete. Fuselage is then finished.

Formers and 1/4" square longerons of the

turtleback are temporarily pinned to the fuselage. After planking the structure

is removed. This ensures a perfectly matched fit. Formers and 1/4" square longerons of the

turtleback are temporarily pinned to the fuselage. After planking the structure

is removed. This ensures a perfectly matched fit.

Wing requires no explanation except - any thoughts of lightening the structure

are to be discouraged. Particularly, the rather lavish use of 3-ply is most necessary

for adequate landing gear support, though it is quite satisfactory to use poplar

rather than the heavy hardwood 3-ply. With the wing properly located in the fuselage

saddle, construct the fairing on the underside. of the center section in such a

manner that the fuselage contours are continued. There is usually enough scrap left

over for this little job; if not, the fairing may be carved from a block and hollowed

out.

Tail surfaces are intended to provide both rudder and elevator control. Even

if a rudder-only system is used, the elevator comes in handy for trim if attached

with soft wire pegs instead of hinges. It is suggested that the tail assembly be

cemented permanently to the fuselage, but rubber bands may be used if desired.

Landing gear is of simple torsion bar design. The rear clip of soft aluminum

is strong enough to keep the strut in place except in the very hardest landings,

in which case the gear merely flips forward and off without damaging either itself

or its support. (Further construction details on the full-size plans.)

R/C Minx Plans

Full-size plans for Northern Minx are on Group Plan #556 from Hobby Helpers.

770 Hunts Point Ave., .N. Y. C. 59 (50¢).

Posted July 8, 2023

|