|

I did a quick Web

search on how to repair damaged book bindings, and as is typical, most of what

is out there is a rewritten regurgitation of other pages. Tape and glue are the

order of the day per those instructions, but that is really insufficient to

effect a good repair on books - particularly older volumes - which use string

and fabric along the spine to form a very rugged and durable binding for

standing up to repeated use. When you desire to restore a book to as close to

its original condition as possible, the more extensive method described in this

1965 Popular Mechanics magazine article is needed. All the tools and

materials required are described, as is instructions for assembling a book

binding press to compress the pages to form a minimal thickness, and to prevent

the spine edge from ending up thicker than the rest of the book.

Rebinding Damaged Books

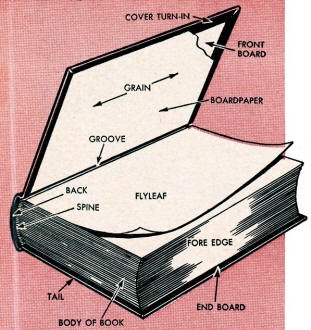

Anatomy of a book.

By Manly Banister

Nobody should throw out a good book just because the binding is damaged. Chances

are it's one of your favorites, for these always receive the most handling. Often,

the damage can be repaired in a couple of minutes with a little glue or paste. Sometimes

a complete tearing down and rebinding may be required. But in either case the investment

in time and materials is negligible when balanced against the result.

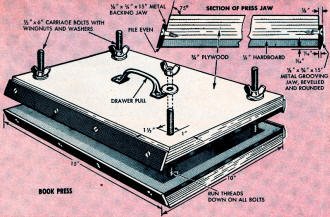

You don't need a lot of expensive equipment to repair books. The most important

piece of equipment is a book press, and the easy-to-build unit detailed on the opposite

page is quite satisfactory for most jobs. In addition, you'll need scissors; a ruler;

a hammer or mallet; a bone "folder" (or make a wooden one by curving the ends of

a flat stick and rounding the edges); a sharp knife, and a large needle.

Materials used in repairing books are also inexpensive. In addition to the paper,

mesh-cloth "super," cover boards and book cloth, you'll have to buy a spool of #25

linen thread, a cake of beeswax (for waxing the thread), a small can of hide glue

and a jar of library paste. All of these may be obtained at a bookbinder's supply

house.

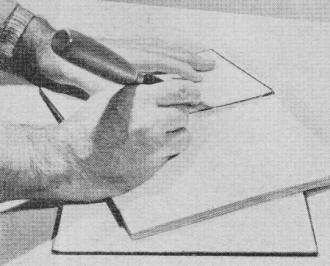

One thing to keep in mind when repairing books: Paper, like wood, has a grain

running in a given direction, and every piece of paper put into a book must have

its grain running vertically, from the head to the tail of the book. Otherwise,

it's bound to buckle and cause trouble. One simple way of determining the direction

of the grain is to fold a sample sheet and wet the crease. If it dries smooth, the

grain runs parallel to the fold. If the crease buckles. you've folded the paper

across the grain.

A homemade book press, a few common tools, and you'll be able

to handle anything from a torn hinge to a complete rebinding

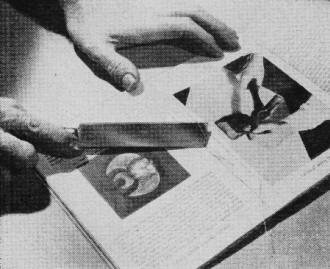

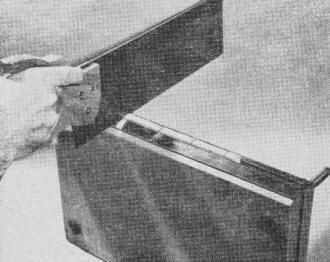

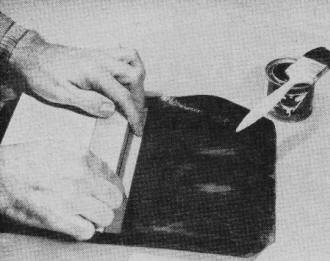

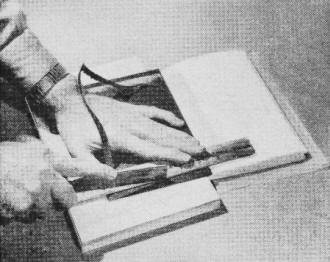

1 - With a sharp knife, cut through the hinges on both sides

to free the body of the book from covers.

2 - Clamp book in the backing jaws of the press and scrape

off all the paper backing, super and glue.

3 - Starting with the first section, find the center and cut

each stitch. Do the same to all the sections

4 - Separate body into sections and flatten the groove in each.

Cover with paper to prevent damage.

5 - If outside sheet of section is torn, repair it by pasting

a 1/2-in. strip of bond paper over the tear.

6 - Reassemble body, stacking sections fold to fore edge in alternating

groups. Keep in press overnight.

7 - Use a dull saw to make four unequally spaced cuts about 3/32

in. deep in spine of collected sections.

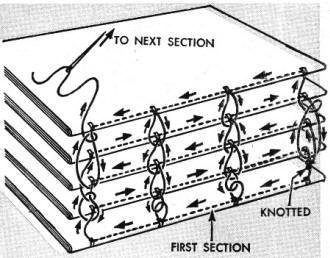

8 - Sew sections together using the lockstitch shown above. This

is described in detail in the article.

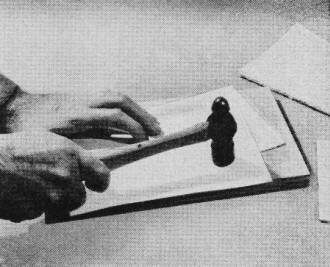

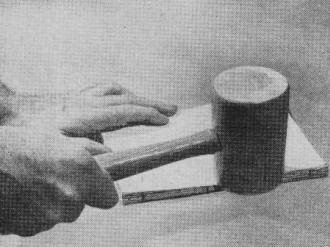

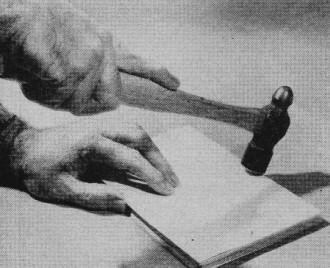

9 - Sewing thickens the spine, but pounding with a hammer or

mallet will embed threads in the folds.

10 - To attach new endpapers, apply a 1/4.in. strip of paste

down the folded edge of outside sections.

11 - After applying flexible glue to spine, tap it into a rounded

shape before the adhesive has set.

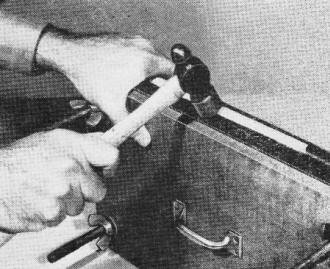

12 - With book clamped in angled backing jaws, turn edges of

sections outward with glancing blows.

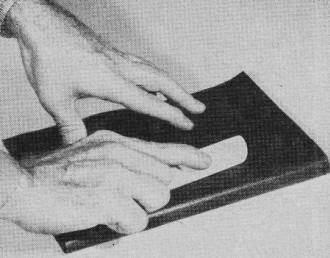

13 - Once shaping of spine is complete, apply a thin coat of

flexible glue and rub it in well with fingers.

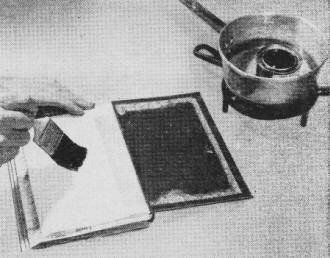

14 - Cloth backing, or "super," should be rubbed down into glue,

then covered with a strip of paper.

15 - When bookcloth has been cut, position body and boards on

it and glue spine-size paper in place.

16 - With body in position, glue bookcloth to boards, working

out the excess glue by rubbing with folder.

The following steps, numbered to correspond with the illustrations, cover a complete

rebinding. This will probably only be necessary if the book is in very bad shape,

with the sewing loose and sections coming apart. To repair less severe damage-broken

cover boards, torn flyleaves, etc. - simply follow the appropriate steps.

Step 1. Cut the body of the book free of its cover by slashing

through the hinges on both sides with a sharp knife. Tear off the flyleaves and

throw them away.

Step 2. Clamp the book in the angled backing jaws of the press

and dampen the spine. (If old glue is really hardened, spread on a layer of library

paste and let it stand a while.) Scrape off the paper backing, the mesh super and

the glue, down to the folds of the sections.

Step 3. The body of the book is composed of sections called

"signatures" in the trade - a series of sheets folded together, usually forming

either 16 or 32 pages. Find the center of the first section, disclosing the sewing

thread, and cut each stitch down the gutter. Do the same to the rest of the sections.

Step 4. Carefully separate the sections. Note that each is creased

close to the fold. This is the "groove," formed in the backing, and it must be hammered

out. Protect the face of the section with a sheet of waste paper and hammer out

the groove, one section at a time.

Step 5. In separating sections, it often happens that the outside

sheet of a section becomes torn. Before resewing the book, it is necessary to repair

these sheets. Cut 1/2-in. strips of 11-lb. bond paper, or similar, as long as the

page. Layout the damaged sheet or sheets with the inside of the fold up. After applying

paste to the strip, stick it over the torn fold, being careful not to stretch the

paste-dampened strip. Then rub it down and put the sheet aside. When all such sheets

have been repaired, gather them together with protective sheets of waxed paper between,

squeeze for a few minutes in the press, and lay them aside to dry.

Step 6. Reassemble the sections and stack them with the fold

to the fore edge in alternating groups of two or three. Place a sheet of waxed paper

or aluminum foil on each side and run the press wing-nuts down as tight as you can.

Let the sections stand under pressure overnight.

Step 7. Take the sections out of the press and assemble them

in the proper order. (Take care you don't put a section in upside down!) Clamp them

in the backing jaws of the press, leaving about 1/4-in. projecting. Make four or

more unequally spaced marks across the back, and saw each mark with a dull saw about

3/32 in. deep (deep enough to cut through the innermost fold of each section). The

head and tail sawcuts should be placed 3/4 in. from ends of spine.

Step 8. Sewing by the lockstitch method has the advantage that

no special equipment is needed. Lay the first section face down on the edge of the

worktable.

Thread the needle with a couple of feet of thread. Pass the needle into the tail

saw cut at the head. Draw loops of thread out through the other sawcuts with a crochet

hook or poke them out from inside with the eye end of the needle. Lay on the second

section, pass needle in through sawcut at head and out through next sawcut down

the back. Pass needle upward through the loop protruding from the section below

and back into the same sawcut. Draw the loop firm (but not too tight) to form the

lockstitch. Finish sewing section one to section two and tie the two threads together

at the tail sawcut with a square knot.

Section three and all following are sewed in the same manner, except that there

are no loops protruding. Pass the needle behind the stitch in the next lower section,

then back into the section, out at the next saw cut, and so on.

At the end of each section, the section is anchored to the one below by means

of the "kettle stitch." Pass the needle behind the thread below, then bring it around

and up through the loop of thread thus formed and draw it snug. When you come to

the end of the thread, tie on another length so that the knot ends up inside a section.

When the final section is sewed on, finish off with a couple of kettle stitches

down the back and cut off the thread about an inch long. This will be glued down

to the spine of the book.

Step 9. Sewing leaves the spine thicker than the rest because

of the bulk of the thread. "Knock down the swell" with a mallet or hammer, embedding

the threads in the folds.

Step 10. New endpapers may be made from regular endpaper stock

(obtainable at any bookbinding supply house) or any other strong paper, even Kraft

wrapping paper. The fold is made with the grain, and the folded sheet should be

exactly the size of the body of the book. Protecting the face of the book with a

sheet of paper, apply a 1/4-in. strip of paste down the folded edge. Then lay the

endpaper over the body and rub it down. Turn the body over and attach the other

endpaper in the same way. Let it dry under a pressure.

Step 11. Normally, the book won't need trimming. However, if

the sections are badly uneven, have a printer trim about an eighth of an inch from

all three open edges with a guillotine. Apply a thin coat of flexible glue or Liquid

Cloth to the spine. (You can make flexible glue by adding 1 1/2 teaspoonsful of

glycerin to an ounce of liquid hide glue.)

Then, before the adhesive is wholly set, tap the spine into a rounded shape with

the hammer. Push in the fore edge with your thumb while drawing the top sections

toward you with the fingers.

Step 12. To complete the backing, place the body in the angled

backing jaws of the press, leaving 3/16 in. of the endpapers exposed on each side.

The idea here is to turn over the sections from the middle toward each side, reforming

the groove noted before you tore the book down. Draw the hammer toward you with

each stroke, making glancing blows that tend to turn the fold-edges of the sections

toward you. Work the full length of each side of the book until a smooth, rounded

spine is obtained, with edges bent over against the metal jaws of the press.

Step 13. Apply a thin coat of flexible glue to the spine of

the book and rub it in well with your fingers.

Step 14. Prepare a piece of super (a mesh cloth) or crinoline,

obtainable from a dry goods store. (Unbleached muslin can also be used, or canton

flannel, stiffened by dipping in a starch solution. Iron the flannel when dry.)

The super should be long enough to reach from tail kettle stitches to head kettle

stitches and wide enough to overhang the book 1 1/4 in. on each side. Rub the cloth

backing down into the glue. Now cut a strip of Kraft paper, or ordinary newspaper,

as wide and as long as the book's spine, and glue it over the cloth.

Step 15. To cover the book, you will need bookcloth or Fabrikoid,

obtainable from a bookbinder's supply house. (For this you can substitute paper,

leatherette, or even automobile upholstering plastic in sheet form. If the upholstering

plastic has a cloth backing, remove the cloth.) Do not use ordinary cloth or anything

else that will let the glue soak through and spoil the appearance of the book.

You can use the old boards or make new ones from mill board or heavy cardboard.

Be sure to cut the boards with grain running from head to tail. Make them the same

size as the old boards if the body wasn't trimmed; otherwise, make them as wide

as the body and 1/4 in. longer. When 1/8 in. is left at the back edge for the groove,

the boards will overhang the fore edge 1/8 in. all around.

Cut the bookcloth to wrap completely around the book, plus 3/4 in. extra at each

end and 3/4 in. along each side. Mark a rectangle the exact size that will be covered

by the book on the inside face of the cloth, then coat it with thin runny glue.

(If the glue is thick, thin it by heating in a pan of water.) Clip off all four

corners of the cloth to within 1/8 in. of the corners of the rectangle.

Lay the end board on the glued cloth in exact position, then position the body

of the book on the board. Cut a strip of Kraft paper as wide and as long as the

book spine and glue it to the bookcloth, as shown in the photo.

Step 16. Don't hurry! Glue sets slowly. Check everything for

squareness as you go along. Lay on the front board so that it overhangs evenly all

around, leaving a 1/8-in. groove between the back edge of the board and the turn-up

on the book. Bring the cloth tightly over the back of the book, lay it down on the

front board and rub it down with your folder. Use the rounded edge to rub in the

groove. Work the folder from back edge toward fore edge and to-ward head and tail

to work out any excess glue. (A sheet of waxed paper under the board will prevent

glue from running on the edges of the book). Now, turn the book over and rub down

the other side.

Step 17. Remove the case (as the cover is called) from the body

and lay it board-side up on the table. Turn the cloth over the edge all around and

rub down the turn-in, squeezing out all excess glue, which can be wiped up with

a damp cloth.

Step 18. Return the body of the book carefully to the case.

Place waxed paper or foil between the boardpapers and the boards and wrap another

sheet around the book. Insert in the grooving jaws of the press and tighten the

wingnuts. Tear the foil away from the back of the book and pick out and shape the

corners of the cloth with a pointed folder or stick. Leave the book in the press

overnight.

Step 19. Remove the book from the press and separate the case

from the body. If the case is stuck along the edges of the back so that the body

can't be freed, don't worry about it. The turn-in is trimmed only on the boards.

(Don't ever try to trim it across the spine, or you'll cut through the cloth and

spoil the case.) Mark the turn-in 3/8 in. wide around the open edges of each board

and trim out with a sharp knife and straightedge. Pull out the excess cloth and

discard it.

Step 20. Place newspaper under the boardpaper to protect the

book and coat the face of the boardpaper with thin glue. Glue the super tab down

to the boardpaper, but keep glue out of the groove.

Close the cover on boardpaper, then open and rub the boardpaper down with your

fingers. Withdraw the newspaper, replace it with waxed paper or foil and close the

cover, then glue the second boardpaper.

The book is now ready for a final pressing. Be sure to have waxed paper or foil

between both boards and the book to prevent moisture from soaking through. Wrap

waxed paper around the book and place it in the grooving jaws of press.

The title can be handlettered, typed, or printed if a small handpress is available,

on a piece of colored artpaper. Glue the title to the back of the book and leave

book in press at least 24 hrs.

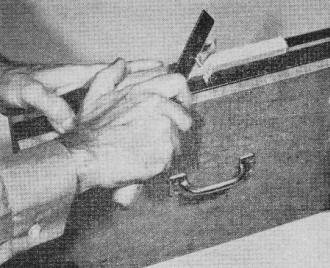

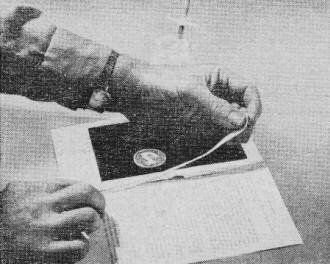

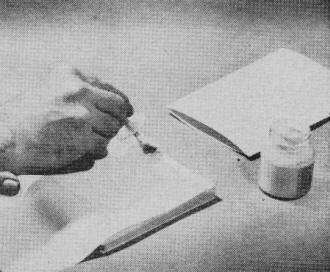

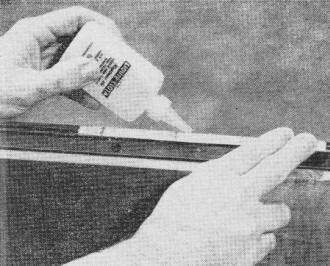

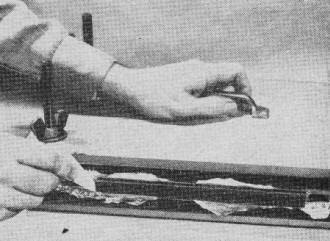

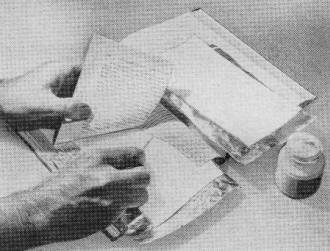

Repairing a Torn Hinge. Where one or both boards are pulled

away from the body of the book, cut the board free from the body of the book and

lay it back. Then glue a strip of super to the spine (with flexible glue) covering

its full width, plus about 3/4 in. to form the new hinge. Glue a strip of newspaper

backing over the super. Cut a strip of Kraft paper 1 1/4 in. wide and as long as

the page. Fold over 1/4 in. along one edge, paste this to the flyleaf and rub it

down. When dry, apply paste or hard hide glue to the strip, as shown in the photo,

fold the super over it and rub down. Close the board on the book with waxed paper

under the Kraft strip and press be-tween the grooving jaws for 24 hrs.

To avoid breaking the back when the rebound book is opened, open it this way:

Stand book on spine and let covers fall open. Open the book a few sheets at a time,

a few at front, and rub them down in the groove; a few at the end, and rub them

down. Continue thus until the middle of the book is reached.

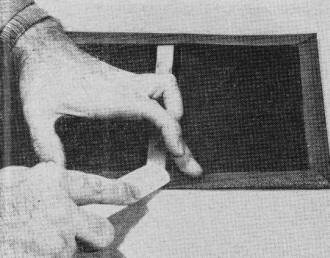

17 - Remove case and turn excess cloth aver edges all around,

squeezing out excess glue with the folder.

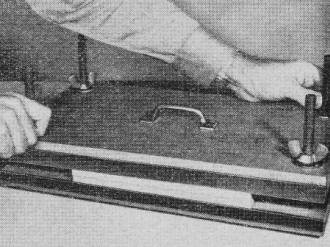

18 - Replace body in case and clamp book in grooving jaws of

press. Shape corners and let dry overnight.

19 - Trim excess turn-in on boards (not spine) to leave about

3/8 in. around edges. Use a straightedge.

20 - Glue boardpapers to boards and place completed book in grooving

jaws for final 24·hr. pressing.

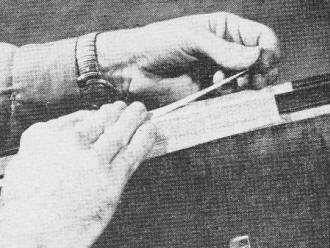

Repairing a Torn Page. Lay a piece of foil or waxed paper under

the torn page and top it with a piece of cleansing tissue. Using a toothpick, apply

library paste to the edge of the tear only. Bring the torn edges together and rub

with the finger. Lay on a piece of cleansing tissue, topped with foil. Close the

book and press overnight. Remove foil and tear away cleansing tissues. Clean off

adhering paper fibers with an eraser or razor blade.

|