|

New airfoils today are designed by computer - literally. As with

circuit and mechanical simulator software, aerodynamic fluid flow

algorithms exist that will run thousands of iterations on an initial

design until it reaches the goal set by the engineer. Limits are

defined on parameters such as chord, wingspan, airspeed, thickness,

manufacturing tolerances, temperature coefficients, material stiffness,

to name a few, and then a mouse click sends the computer into its

happy place while obeying convergence rules and arriving (hopefully)

at a solution that provides the performance characteristics desired.

If it fails to produce the expected result, a new set of starting

points, limits, and convergence algorithms can be stipulated and

then the process is run again. The engineer can focus his attention

of other pressing matters (like drinking a cup of coffee) while

the computer does his bidding.

Prior to the computer age, airfoils were designed according to

a set of rules empirically determined through wind tunnel testing

of many varieties of shapes. The original work was performed by

the National Advisory Committee for Aeronautics (NACA)

- forerunner to today's NASA. Volumes were published on airfoils

meant for particular applications - speed, heavy lifting, short

field operations, high altitude, etc. Nowadays rather than thumbing

through a tome that takes two men to lift, you simple click on a

pull-down menu and there you go.

Ritz on Airfoils

One of modeldom's best known designers has distilled all current

state-of-the-art data on wing sec-tions down into a single you-read-it-at-a-glance

chart

By Gerald "Jerry" Ritz

A common question is "How do you go about choosing the best airfoil

for a projected model design?" The answer to this is that there

is no single best airfoil for a model except in calm air with no

turbulence to produce variations.

Max Hacklinger of Germany, one of the world's keenest minds on

airfoil design, had this proven to him decisively at the Nordic

World Championships on two occasions, when with undoubtedly the

best model for pure glide duration, he wasn't able to squeeze by

the downdraft air factor to which high performance models are especially

susceptible. He has since then switched to indoor models where his

scientific skill will not be subjected so much to the vagaries of

the air.

Of course, we can choose the best general area of airfoils for

any given design, with a refinement of choice for given weather

conditions. To do this we have to make an analysis of the design

factors of airfoil sections.

One of the best all-around methods for describing the physical

characteristics of airfoil sections for use in model aircraft is

undoubtedly the 4 digit system as originated by the N.A.C.A. Here

is stated the essential proportion of height of mean camber, with

its positioning, and the maximum overall thickness of the section.

One of the factors not found in this 4 digit system is the data

on body form, inasmuch as the NACA used standardized thickness forms

in most of their early sections. (Of course, on specialized high

performance sections such as some of my glider sections and some

of Benedek's top performance sections, it is necessary to depart

from these standardized body forms.)

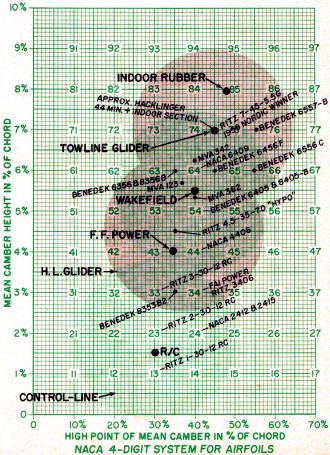

Now in a further analysis of this 4 digit system (which actually

consists of 3 descriptive features: 1st number - Height of mean

camber in percent of chord; 2nd number - positioning of this mean

camber high point in tenths of the chord from the leading edge;

3rd and 4th numbers - maximum thickness of the section in percentage

of chord) we find that each descriptive feature has a definite relationship

to the type of model on which the section is to be used. To illustrate

the various general areas into which different types of models will

fall, we have laid out a chart diagramming the two basic airfoil

features - the height of the mean camber, (6409) and the chordwise

high point of this camber, (6409). In this example, the first number,

6 means that the airfoil mean camber height is 6% of the airfoil

chord length. The second number, 4, means that the maximum high

point of this mean camber is located at 40% of the chord from the

front of the airfoil.

For example, in a speed model or in a plane designed for aerobatics

such as a radio control contest job, very little height of mean

camber would be used. The reason here is that in these cases the

wing is used mainly for neutral suspension of the model, and for

purposes of control, and very little positive lift (which is a feature

of camber) is required. Because of this, the camber for this type

of model will range from 0% for use with high speed jobs, to a high

of about 3% in slower flying scale R/C jobs.

In engine powered free flight models, however - the object being

duration - we must necessarily use some camber to obtain enough

lift for a good glide. However, the amount of camber we can use

is limited by the fact that the power phase of the flight is at

quite high speed and too much camber would create too much lift

and be hard to control, and also it would create too much drag,

which would slow down the speed thereby reducing the climb which

is so necessary for good duration. Therefore in this case we use

moderate cambers, with a low of about 3% to a high of about 6%.

Hand launched gliders, with their high powered launch phase, fall

into this same category.

In outdoor rubber powered models, where the power surge is not

so great, it is possible to move toward the higher lift sections

characterized by the higher cambers, both for good lift in the power

phase, and principally for better gliding performance. In this type

model the mean camber should range between a 4% low up to a high

of about 7%.

The final outdoor category of pure glide is used mainly by towline

gliders, where the model is towed to maximum height without any

regard for camber or its effect in the tow, and then cast off to

glide. Here we come into one of the highest ranges of mean camber

of any type of model. In this region of pure glide, the most effective

mean camber for duration will fall into the low of 5% up to a maximum

of about 9%.

One factor that will modify the height of the mean camber on

free flight models is that in very windy turbulent weather, the

highly cambered airfoils tend to stall easier. So if a model is

being designed for windy weather, use the lower range of cambers

for greater consistency. For calm weather flying, use the higher

range of cambers for maximum duration.

Now we come to an argumentative phase, which concerns the mean

camber for indoor duration models. Because of the low power surge

of this type of model, where the power flight contains nearly the

whole of the duration pattern, the flight falls into much the same

category as pure glide, except for there being just enough power

added on the average to about maintain altitude. Although some of

the experts have been using lower cambers (down to even 3 or 4%)

for maximum duration on indoor rubber powered models, our figures

show that the camber height should be from a low of about 5% up

to a maximum of about 9%. Following the reasoning as outlined above,

I would venture a prediction that the first man in the "one-hour"

club will use an airfoil camber of about 8%.

NACA 4-Digit System for Airfoils

So far we have discussed only the height of the mean camber.

And very frankly, this is by far the most important criteria of

the three digits. Next in order is the chordwise placement of the

high point of the mean camber. If you will examine the chart, you

will see that the lower cambers used in models generally have the

high point quite well forward in the chord, and as the camber height

increases, the high point gradually moves rearward. There are good

reasons for this. As the camber increases, it is a pretty sure bet

that the Reynolds Number (principally a factor of chord length x

speed) is decreasing - that is, the airfoil is being used on a slower

flying model. This generally means a thinner airfoil to get more

undercamber, as tests have shown that the undercamber of an airfoil

carries a gradually increasing proportion of the load at lowering

Reynolds Numbers. With this increased undercamber, care has to be

taken not to allow too high an undercamber entry angle, or there

will be a stagnant area with loss of lift and increase of drag.

To help avoid this, the high point of the undercamber can be moved

rearward. This automatically shifts the mean camber maximum high

point rearward also. In conjunction with this, the higher trailing

edge undercamber angle of a rearward location of maximum mean camber

will produce considerable additional lift without too much drag.

Care must be taken not to overdo this, however, as lift produced

by trailing edge deflection builds up quite fast, and in this critical

Reynolds Number region, can produce a stalled condition rather easily

in turbulent air.

Therefore we can draw the following conclusions: When choosing

an airfoil for use on a model for turbulent air, do not use too

much camber, and keep the high point of the mean camber fairly well

forward - (lower left hand area of the circle). For calm air flying,

however, use the higher cambers, with the camber high point more

rearward (top right hand area of the circle).

An interesting observation is that the camber of Hacklinger's 44·

minute indoor model and the mean camber on my "Continental" Nordic

glider were nearly identical.

The large X in each circle is a suggested ideal choice of camber

for average weather for the type of model portrayed by that circle.

The third factor of the NACA digits is the maximum thickness

of the section measured in percent of the chord. Here we have two

prime considerations. One is the matter of structural strength,

and, of course, the thicker the airfoil, the greater the strength

that can be built into it. The other factor is the matter of efficiency,

where in these low Reynolds number regions the thin sections have

a higher L/D ratio than the thick sections. Here again the weather

factor enters into the problem. The thicker sections are more tolerant

of rough weather conditions. They have a more gentle stall, and

their center of pressure shift is generally much less violent, mainly

because of the greater movement of the air separation point on the

round nose of the thicker sections. Thus they are easier to control

in turbulent air.

However, this very roundness of the nose of the airfoil that

makes control less difficult in turbulent air, is a decided disadvantage

in calm air, especially in the lower Reynolds number region. Here

we count to a large extent on the small radius nose to help provide

enough natural air turbulence over the airfoil to prevent the early

breakaway with high drag so attendant to airfoils flown at low Reynolds

number in a lifting condition.

In R/C contest models, where the Reynolds number is fairly high,

one of the main differences between a thick or thin section is that,

as stated before, the round nose of a thicker section will be more

tolerant to control than a sharper nosed section, and the section

will have more drag and "grip" on the air, thus allowing patterns

to be flown more slowly.

So if you are a beginner in R/C by all means use a thicker section

with a round nose to get a smooth, more sluggish control that you

can keep up with. However, a real expert with a good control unit,

who can handle high-speed maneuvers, can get sharp and decisive

patterns with a thinner, sharper nosed section at speeds a beginner

could not hope to handle. In years ahead, look to the time limit

in R/C to become increasingly important as a judging factor in contest

flying. I would suggest points be given for total time saved in

flying the prescribed patterns.

As we enter the free flight range, with the duration factor to

contend with, we are immediately forced into the thinner type sections

for purposes of efficiency. In free flight power, for example, a

10% thickness of section would be about the maximum anyone would

go to, and many of the high performance jobs, especially in the

FAI classes, are down to about 6% thickness. In Wakefield models

and Nordic gliders, the thickness is down even more in many of the

best models.

By this time you can see the general trend: As the Reynolds number

the airfoil is flown at is decreased; the overall section thickness

is decreased also. The limiting factor in most cases of outdoor

models is either structural or that oft-repeated turbulent air problem

where a thin section coupled with high camber may not give you the

necessary consistency for contest flying.

The final phase of the thickness category is, of course, the

indoor duration models, with the lowest Reynolds numbers of all,

and appropriately the thinnest sections of all ... and here where

we don't have to worry unduly about turbulent air. We can freely

go to the thinnest of sections and the greatest cambers for maximum

efficiency, and naturally have the greatest duration potential of

any type of model.

The next time you design or build a model, keep in mind the three

criteria of the NACA digit system, and pick your airfoil carefully

for the type of model you have in mind, and for the conditions you

intend to fly it in, and it won't be long until you'll be giving

some of the experts a real "run for the money".

Posted June 13, 015

|