|

Reading through this article reminded me of how dedicated some modelers

are today and have been in the past in their efforts to advance

the state of the art. The ingenuity of people often makes me feel

like a real dope by comparison. Mechanical and electronic devices

conceived of, built, tested, improved, and perfected by our aircraft

flying brethren are truly astounding. This "Pi-Bar" invented by

Gerald Ritz is a simple tool to "make it easy to lay out a propeller

of any blade shape, area, or pitch, with absolute accuracy and without

computations or the use of formulae." I wonder how long it will

be before we witness the first 3-D printed propeller for free flight?

Propeller Layouts Are Simplified with the "Pi-Bar"

By Gerald Ritz

The "Pi-Bar" propeller layout system is the result an effort

to simplify a basic propeller design method to make it easy to lay

out a propeller of any blade shape, area, or pitch, with absolute

accuracy and without computations or the use of formulae.

Basically, it consists of the pitch relationship projected in

scale to the radius of the propeller in inches. Thus this simple

scale allows you to draw out the proper blade angles at various

points of the blade with no figuring whatsoever.

Directions and a simple explanation for using this system will

be given first. Further explanations and pointers for the more persistent

will follow.

Cut the "Pi-Bar" scale out and glue it to a piece of 1/16" plywood

or its equal and when dry trim to the scale edge. Be careful to

use only a thin film of glue so as not to stretch the paper scale

from excess wetting.

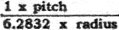

Step 1: Get a sheet of paper and mark off inch measurements along

the bottom edge, starting from the right-hand side, and number these

1, 2. 3. etc. These points correspond to the inch radius points

on your propeller with the starting point as the center line of

your hub.

Step 2: Now place the ''Pi-Bar'' scale on the right side of the

sheet with the "0" point on the scale at the hub starting: point.

Find the number on the scale that corresponds to the pitch you wish

to use and mark the edge of the paper at that point. With a rule,

draw connecting lines from your inch radius points to this pitch

point. This gives you the correct angles that your propeller blades

must be given at the various radius points to have the pitch you

selected.

From this point in the process you can proceed in several different

ways, varying in the amount of effort required and also in the quality

of the results obtained.

Step 3: The simplest method is to draw out the front view of

the propeller blank in the actual size and shape you wish the finished

propeller to have, and mark it off in inch radius marks, numbering

them from the hub out to correspond with your scale on the bottom

of the sheet.

Step 4: Measure the width of the blank at each radius point and

starting at that same radius point on the bottom of your sheet,

mark off this measurement to the right side of this point (on 3"

radius, A-B). Now with a square or 90 deg. angle draw a vertical

line from this measurement point to intersect with the pitch angle

above B-C). The length of this vertical line B-C is the proper depth

for your propeller blank at that radius point. The length of the

pitch line (A-C) will be the width of your propeller blade at that

point. Finish this operation for all the radius points.

Step 5: The next step is to draw out a side view of the propeller

blank, making the outline fit the measurements at their proper radius

points (on 3" radius, B-C).

With the front and side patterns now completed, it is a simple

matter to transfer them to a block of balsa and cut out accordingly.

Be very careful in cutting the blank to cut accurately to the

outline, and in carving, to carve to the very corner of the blank,

and you will get a perfectly pitched propeller with a finished blade

outline.

Keep this pitch layout, as you can use it for other propellers

of different shapes and diameters of that same pitch. If this layout

is made on graph paper scaled to the inch in 1/16 or 1/20 inch divisions,

it will be much easier to do your work accurately.

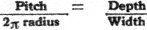

Now for a little more comprehensive data on the subject. The

same relationship exists between the depth and the width of a propeller

block at any point as exists between the pitch and "pi" (3.1416)

x diameter at same point.

Therefore, knowing the propeller diameter and the pitch we may

desire, all we have to do is to layout the pitch/π diameter relationships

in geometrical form and from them take off the correct depth/width

relationships of the block for any width of blade desired. Transferring

these depth and width measurements to the proper place on outline

drawings and connecting the points with a curve will give you an

accurately pitched propeller layout.

Since we want to key out angles for only one blade, we will use

the radius measurements, so the formula actually becomes

. .

Solving further,

or

is the part of. the formula we are using. The inch measurement

for diameters is practically standard, so we have allocated this

scale relationship to the pitch factor. Now since our factor is

if we use 1" as standard for radius per unit, our scale for pitch

will be 1/6.2832" per unit. This measurement is transcribed on the

"Pi-Bar" scale.

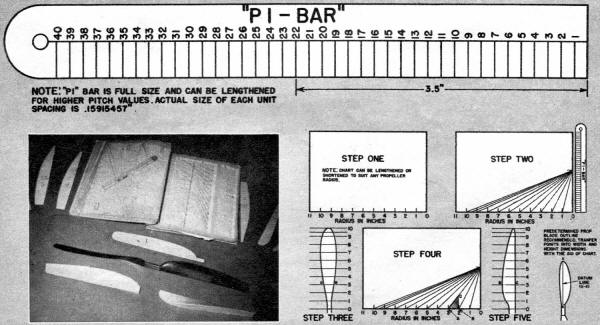

The preferred method of procedure for layouts is to draw out your

actual finished blade shape with the proper amount of area, draw

the radius lines on this planform, and transfer the width measurements

on the pitch lines. It is a good practice to put a half-inch radius

line next to the tip to get more accuracy at this vital point. Vertical

lines dropped to the bottom of the sheet will give you both the

width and depth of the blank at those points to obtain the desired

pitch and finished blade width. Transfer the depth measurements

to one planform and the width measurements to another planform and

connect the points with a French curve for the final outline.

To lay out your patterns to get the exact blade shape, you will

have to work to a datum line (X-X) when transcribing the width and

depth measurements. The point where this datum line bisects the

blade width will have to be marked on the pitch line and a vertical

line dropped from this point also to get the proper split of measurements

for the profile of the blank.

Using this system, you can obtain exactly the blade shape you

desire, with the maximum area positioned where you want it, you

can fit the prop to your fuselage upon folding, etc., merely by

starting your operations from the proper point.

The possibilities are many, and if you play around with this

system a little to get used to it, you'll never go back to the old

"X" block method.

Propeller Layouts Are Simplified with the "Pi-Bar"

Posted February 8, 2014

|