|

Most people these days are

probably now aware of an aeronautical profession that up until around the early

1980s was a vital part of aviation - the

flight

engineer. This 1950s article in Air Trails magazine highlights what

was at the time a very prestigious and sought-after position for people wanting

professional level careers in both commercial and military aviation. Since the 1930s, aircraft were rapidly growing larger and more complex. Most had two

to four engines, retracting landing gear, pressurized cabins, autopilots,

electronic and celestial navigation, long distance routes, and increasingly

crowded airways. All that plus en route and destination airport weather, and

even ground traffic clutter at airports had become more than a pilot and copilot

could safely handle along with just flying the airplane. Thus was born the

flight engineer position. His job was to monitor all the sensor gauges, monitor

and provide corrective course line data to the pilots, keep track of weather,

monitor for air traffic, handle onboard systems operations, and many other

duties. A flight engineer job was a great alternative to piloting if a person

either did not have the desire to fly the airplane, or could not qualify due to

medical conditions (e.g., less than perfect uncorrected eyesight). It was also a

great way to build air time while working on obtaining a pilot position.

Your Job in Aviation: Flight Engineer

"The Third Man" is the theme of this career report; the flight engineer is a

specialist whose field is growing every day.

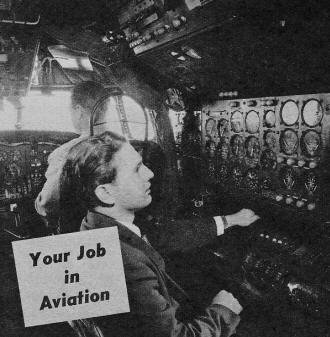

Jack Allen turns his head slowly, staring at a multitude of gimmicks. He's sitting

at the flight engineer's station in the crew compartment of a Constellation mockup. Jack Allen turns his head slowly, staring at a multitude of gimmicks. He's sitting

at the flight engineer's station in the crew compartment of a Constellation mockup.

Left to right, Jack fingers master propeller control throttles, super-charger

controls, mixture-tank valves, carburetor air, cowl flaps, feathering, fuel boost,

oil cooler flap. Altogether, Jack flips 25 engine and 14 propeller controls, 25

fuel valves, 22 oil switches and valve controls, and 10 heating switches.

Within easy reach he sees exactly 295 gadgets, all able to do something to tell

him what's going on inside the many mechanical assemblies that fly the aircraft

and keep the passengers comfortable.

Jack is an embryo flight engineer, Those scores of dials and gauges knobs seem

appalling for the moment. During the next 12 weeks he will study and handle them

every working day. He will bone up on his mathematics - algebra, plus a smattering

of trigonometry. Later 50 hours of transitional air training will knock off the

rough edges.

Soon Jack will be flying on regular schedule with one of the air lines. His acceptance

means he now is a specialist. Not a mechanic, not a pilot, he's the third man of

a smoothly operating team. Actually, he becomes the mechanical side of the pilot.

There are several thousand like him in the business today, if you include the armed

services. His job is expanding, and will continue to do so as aircraft grow larger

and more complex.

Sitting at the gauge-dotted console, only a few feet aft of the pilots, Jack

will handle engine power, cabin pressurization, air-conditioning, and the electrical

and hydraulic systems. It is he who will control fuel mixture, feather the props,

dump fuel in an emergency, depressurize the cabin if required.

Jack might be considered a preventive maintenance man. Lots of thought has been

given to prevention in recent years, ever since the Air Force set out to learn what

was downing B-29s in the Pacific during the war. He will learn to interpret, through

manifold gauges, and indicators, what the engines try to tell and him. Like a doctor

listening through a stethoscope, he will learn when the beating hearts are about

to fail.

More broadly, Jack and his kind are safety addictives. The CAA agrees that most

accidents occur only after the pilot has reached the point, through fatigue and

time, where he cannot use his head to think out a plan of action because he is using

his hands in too many directions.

Jack wasn't aboard when a north-bound Connie put down three times in zero-zero

night landings not long ago. An older and more experienced flight engineer sat at

his station that night. Rain was falling from 8,000 feet as the plane roared into

the traffic pattern at Washington, D.C. To the crew, dove-tailing their duties with

symphonic precision, it was only another let-down. The captain, sitting at ease,

handled the radio. At intervals he called out instructions. His copilot flew the

plane according to the captain's orders. For his part, the flight engineer juggled

power settings, dropped the flaps, made other fine adjustments, finally cut the

power. They were down on the first approach. Twice again that night those three

people landed the plane zero-zero, at LaGuardia and Boston, with first-time approaches.

The captain had confidence in his first-officer, and both trusted the flight

engineer to do his job efficiently and safely!

Jack knows he will stick to reciprocating engine aircraft for several years,

at least on commercial runs. From his transition flights, he has learned that modern

planes have become flying power stations - their generators turning out enough juice

to light a small town. His biggest worry is whether he will do his job well and

- offload worry from the captain.

"Pilots," he confides, "have become so confused, handling scores of knobs and

watching hundreds of dials, they literally couldn't make a decision. I don't want

to be flying when my captain makes a serious mistake because I've got a job with

a future and I want to be around when the future arrives."

Jack isn't worried too much about the advent of jet transports. He knows the

CAB requires flight engineers on all planes grossing 80,000 pounds or more. It isn't

likely, the passenger-carrying jets will weigh less. Should they become lighter,

the rules may change in his favor.

True, the experts differ on the question, will the jets need flight engineers?

Some argue that, with increasing speeds, the coming planes will go from here to

there before engineering services aloft will be required.

"But," says Joe Towle, Lockheed's chief pilot, "look at it this way: The pilot

doesn't care how the engines are operating, or how much power they're putting out.

He's interested in the total results of whatever power he has - as the airspeed

and rate of climb. His job is enormously simplified when he can disassociate himself

from details of operation."

Jack may ,get the nod one day, and find himself tending the controls and myriad

instruments on a transatlantic jetliner. He'll make the crossing much faster than

do the Connies and DC-Sixes. John Cunningham, DeHavilland's chief test pilot on

the Comet, knows how much faster these planes fly than current airline models. He

carries along a navigator on every distance flight, even though the margin of error

through vagrant winds is less than with a slower plane.

"It's important to know exactly where we are at all times," testifies Cunningham.

"There's no time to study charts. Decisions must be made in seconds, not minutes."

The same reasoning recently impelled Cunningham to remark that the jets will

need flight engineers. On a slower plane Cunningham may need to know, at some stage

of flight, how many more minutes of fuel remain in the tanks, how many more minutes

of flying time remain before touch-down. On the jets, he tells you, decisions must

be made fast. Because human reactions have not kept pace with speed-up of machines,

nothing less than training and experience will qualify Jack for that important job.

Civil Air Regulations, Part 35, point out specifically how Jack can prepare for

his first post. He can take his choice among these routes:

Most highly approved, and recommended by operators, is a two-year course in specialized

aeronautical training. One man who knows the requirements is Chuck Mercer, Lockheed's

chief flight engineer. Mercer wants men who have enjoyed a good mechanical background,

the type of training that produces an A and E license. Fact is, all operators of

Constellations, without exception, require their flight engineers to have A and

E licenses. Also, some training should be had in physics and engineering.

Other approaches include three years of diverse practical experience in the maintenance

and repair of planes and engines, including one year on multi-engine ships of 800

horsepower per engine or more; 100 flours of flight experience in the duties of

flight engineer, or 100 hours as pilot of four-engine aircraft.

Should Jack sign on with Pan-American, he would learn his is a respected and

responsible job in a growing profession. His chief would hand him a small, printed

brochure, from which he would learn that the purpose of the engineering officer

position is to furnish the plane a crew member responsible for safe and efficient

functioning of the plane and engines, that he would work under the chief flight

engineer, that he would be responsible to the captain for the safe, conservative,

and efficient execution of his duties.

But what are his duties and responsibilities?

Prior to departure, Jack would satisfy himself that the airplane is airworthy.

He would measure the gas and oil, making certain the quantities meet requirements

of that particular flight.

Once airborne, he becomes responsible for watching continuously and adjusting

properly all the equipment under his care. He must keep complete engineering logs.

If any malfunctioning occurs, he notifies the captain, recommends a course of action,

logs the incident.

After landing, he may assist the station mechanics in repairs - so long as he

gets enough rest to continue his duties aloft efficiently.

Important, too, is the instruction he gives station mechanics in new mechanical

developments, servicing procedures and maintenance problems of the planes operated

by his company.

Jack may have been too young to remember a day when there was not even a copilot.

He'd have to look back to the late Twenties for the beginning of his profession:

Pan-Am took the initial step. The company was operating Sikorsky boats and Consolidated

Commodores over water for long distances. Both the distances involved and a paucity

of good facilities at overseas stations led to an inevitable conclusion. The planes

must carry flying mechanics.

The difference between a flight mechanic and a flight engineer? Considerable.

The mechanic usually goes along to be available for mechanical jobs on the ground.

The flight engineer not only has a major share in operating the airplane during

flight; he is interested in the overall results of efficient and safe flight as

a result of his handling controls, fingering dials, turning valves, and perhaps

making repairs in flight.

Pan-Am early learned that the mechanic was doing a good trouble-shooting job

while in the air. He kept the engines ticking more smoothly. He helped conserve

fuel. The pilot began to rely upon his advice when anything mechanical went wrong.

Then changes began to appear on the newer planes. Flaps, retracting gear, food warming

equipment, multiple gas tanks. There developed a need for very close control of

fuel, together with installation of carburetors which could vary the amount of fuel

fed to the engines. Duties for the flight engineer began to multiply.

By 1934 the flight engineer attained new status. By that year the Martin China

Clipper was hauling cargo and passengers. That plane had a flight range of 20 hours

or better. The China Clipper really fathered the flight engineer. On more than one

occasion, he repaired broken parts during flight. Experience then demonstrated that,

given means to reach them, he could repair engines while airborne.

Next came the Boeing 314 triple-tail Clipper. By crawling out through the

wing, he. could reach all four power plants. Flight engineers wrought what were

then considered minor miracles. By tying a splint made of pencils, one dexterous

FE repaired a broken throttle shaft. Another replaced magnetos while the prop

was feathered. From his station, a flight engineer actually took off and flew

briefly one boat after broken catches dropped the seats away from the pilot, and

copilot. These un-related incidents were not only demonstrating an unsuspected ability of the flight engineer to meet

many demands, but also were developing a teamwork necessary to fly the big jobs

neatly.

The team has now proved itself, and the third member - the flight engineerr - has

a place of growing responsibility.

|