|

Who

doesn't love a classic biplane, especially one with a big radial

engine hanging off the nose? The first plane that usually comes

to mind is the Stearman PT-17.

In fact, if you didn't know better, you might mistake the Pitcarain

Mailwing for a Stearman. Yes, the vertical fin and landing gear

is markedly different, and the Stearman doesn't have the pilot headrest

"bump," but paint a Mailwing yellow and blue, and you might easily

fool a lot of us. This model from the August 1968 edition of AAM,

designed and built by Frank Beatty is for control line. One unique

feature is that the dummy cylinders for the radial engine were constructed

from a plastic

Monogram Wright Cyclone 9-cylinder engine kit. The assembly

drawing and plans are exceptionally well done. The Pitcairn Mailwing

FRANK W. BEATTY Designed for night air mail in 1927 this

plane brought reliability to the Air Mail Service. A control-line

masterpiece for 35 power. The Pitcairn Mailwing was specifically

designed in 1927 to be sold to contract mail carriers for night

air mail runs. An immediate success, this craft which could carry

600 lbs. of mail at speeds up to 136 mph was being produced at the

rate of one per week by the end of 1928. Many an airline that is

world-famous today was equipped with Mailwings during this era.

The model's high-gloss finish reflects prize-winning detail

and workmanship. Lighting can be operative and the engine exhaust

can be routed through the curvaceous manifold.

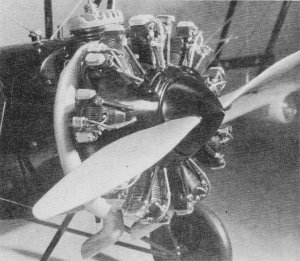

Monogram Wright engine kit was the source of the scale cylinders.

They are mounted on a removable false cowl and are loaded with

lead weight.

The "anti genius" fires up the McCoy 35 R/C. It is well built

and not a light-weight, and is a realistic flyer.

At the field, ready to receive its load

of air mail for the night, our well-detailed Mailwing awaits

action. The cover of the May issue shows a restored mint-condition.

Mailwing at Fredericksburg, Va. Authentic colors and some extra

details were shown.

Many Mailwings finished out their days as crop dusters and a handful

of Mailwings are still flying today. Well preserved examples can

be seen at the Tallmantz and Smithsonian Air Museums. For many aero-philes

watching the TV late movies, the real star of Blaze of Noon is the

Pitcairn Mailwing. James Triggs' fine three-views which

appeared in the January 1959 American Modeler and the Fall 1960

Air Progress were used in preparing the Mailwing working drawings.

Mr. Triggs' drawings did not include coloring data, but replies

to letters sent to Eastern Air Lines, Tallmantz Aviation and the

Smithsonian Institution all verify that the plane was painted as

described in this article. It was noted that if Mr. Triggs' three-views

were to be enlarged four times, the Monogram Wright Cyclone Plastic

Engine Kit would be exactly the right size for this model. The model

has therefore been built to a rather unusual scale of 1 3/16" =

1' and has a 39" wingspan and a 26" length. The ship is powered

by a McCoy 35 R/C engine with a Roberts bellcrank operated throttle

and all up weight is some 51 ounces. It was originally intended

that the Mailwing's construction would follow closely an old favorite

sport scale model built many years ago - Chuck Hollinger's Fleet

Biplane (Air Trails May 1951). Such a model would have gone together

much faster and would have had some stunt capability. But as the

drawings and construction proceeded, more details with their supporting

structures and vast amounts of filler and dope were added until

the model far exceeded its original proposed weight. The Mailwing's

configuration is such that unless some care is exercised in keeping

the model's tail as light as possible, ballast will be required

in the model's nose. Having gone overboard on details and paint,

the Mailwing required some 10 ounces of ballast in its nose; six

to eight of these ounces being packed in the hollow plastic engine

cylinders. Many of my scale models have had wing loadings of 20-25

ounces per hundred square inches of wing area, so this model which

sounds brick-heavy at 51 ounces has a reasonable (for me) wing loading

of 14.3 ounces per hundred square inches of wing area. It has flown

and handled well, even in gusty-wind contest conditions. A model

of 40 ounces or less could be a true week-end sport flyer, so build

to suit your purposes, but DO NOT FLY your model unless balanced

per drawings. Wings: Cut out all ribs,

spars, spar joiners and leading and trailing edges and cement these

frames together. Shape the leading edges and then add all 1/16"

sheet balsa panels and the tip fairing blocks. Epoxy all pre-shaped

spruce strut and rigging blocks in position and then sand both wings

to final shape. Drill the lower wing rear spar for the 1/8" dowel

aileron supports before cutting ailerons separate. This assures

that the aileron will mate perfectly with the wing on final assembly.

Mark all strut and rigging wire locations on the spruce blocks and

drill all strut locations with a 1/16" dia. drill and all rigging

wire locations with a 1/32" dia. drill. Tail surfaces:

Saw the fin and rudder, and the stabilizer and elevators out of

3/16" sheet balsa. If you plan to install full rigging wire details,

cut a 3/16" wide strip off the rear edge of the fin and stabilizer

and cement 3/16" square spruce spars in their place. This harder

wood will resist the sawing action of vibrating rigging wires far

better than the balsa it replaces. For even better results, install

a 1/16" dia. tubing bushing through these spars at each rigging

wire location. Sand these parts to shape and add the Veco control

horn and hinge details to the horizontal tail surfaces.

Fuselage: Cut out the 1/8" sheet fuselage crutch

members and all bulkheads. Lightly score and crack the crutch members

at stations #3 and#8 and cement all bulkheads between these members.

Epoxy the 3/8" x 1/2" maple motor mounts in position (Bulk-heads

#1 and #2). The Roberts bellcrank with lead out wires bolts in next.

It is good practice for every model that one owns that is equipped

with a Roberts operated throttle to idle down or speed up with an

identical trigger movement at the control handle. Otherwise in an

emergency situation when an automatic reflex might save a ship,

confusion and disaster may result. For this reason a Roberts suspended

bellcrank was installed in an upright position in my model. Analyze

your own fleet of models and the throttle throw of the engine you

will use to determine the proper bellcrank for your model. Temporarily

bolt the engine and pin the horizontal tail surfaces in place to

make up the throttle and elevator linkage wires. Make sure these

move without binding before proceeding. Some slight bending of the

bellcrank pushrod horn will probably be required if the suspended

bellcrank is used.

Make

up the cabane and landing gear struts, then bind and epoxy these

into place. Four of the landing gear struts have short bent-over

ends that pass through the bulkheads to help position and prevent

shifting of these struts during installation and on hard landings.

Epoxy the fuel tank with its special modifications into position

next, followed by all stringers and balsa filler blocks. Make up,

finish and install the cockpit floor and all cockpit details. Epoxy

spruce rigging wire locator block to top of Bulkhead #1 and then

plank fuselage top from Bulkhead # 1 to #4. Do not cut cockpit opening

till after all sanding, doping, and rubbing is completed. Bind 1/16"

dia. aluminum tubing rigging wire locator to Bulkhead #1, install

lower wing spar support, then sheet cover fuselage bottom from Bulkhead

# 1 to # 3. Add tailskid detail. Make up cowling block, hollow same,

fit to model and carve to shape. Note that cowling slides forward

to remove leaving an unsightly hole aft of the McCoy cylinder head

which must be filled with a balsa block that is permanently cemented

to Bulkhead #1. Sand the entire fuselage/noseblock assembly to final

shape and cover these parts with silk. Install all cabane strut

and landing gear strut fairings and reinforce these with silk wrappings.

Assembly: Toughest problem for most people

who attempt biplanes is the finish, assembly, alignment sequence.

Our goal with this model is to be able to dope and rub down all

parts separately and then have all these finished parts cement into

pre-drilled holes that automatically align the wings during final

assembly.

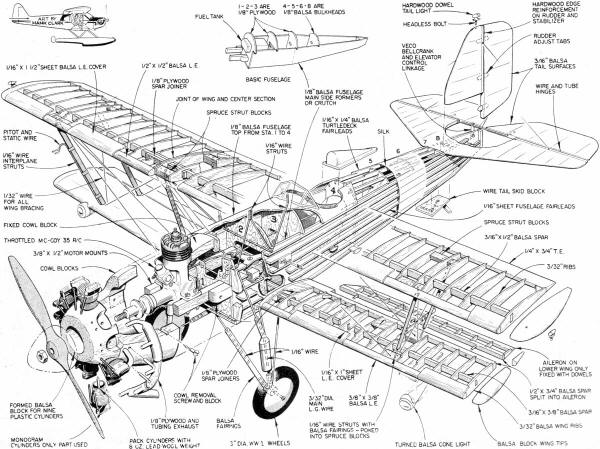

Pitcarain Mailwing Assembly Drawing

<click for larger

version>

Slide the lower wing into position, check for alignment and

cement well. Pin the three balsa wing alignment templates to the

top wing and slide the upper wing into position. Trim just enough

of the balsa cabane strut fairings away so that the center template

rests on the fuselage top when the cabane strut ends have been fed

into the pre-drilled spruce blocks. Bend each 1/16" dia. wire interplane

strut to size and slip into the pre-drilled spruce blocks. After

all interplane struts are fitted, check the assembly for alignment

and pin and tape the whole together rigidly. Solder the brass line

guide to the port pair of interplane struts and then fit all interplane

struts with balsa fairings. It is important for each strut fairing

end to be a close fit. The assembly can now be dismantled and the

struts with their balsa fairings will automatically align the top

wing during future fittings. Set the alignment templates aside,

reassemble and tape the top wing into position again. All the 1/32"

dia. rigging wire can be bent and cut to size and temporarily fitted

in the model. Label each rigging wire with masking tape before dismantling

assembly once more. Soft copper wire can be wrapped and soldered

to each strut or rigging wire end in widely spaced coils. Enlarge

all 1/16" dia. pre-drilled strut location holes to 3/32" dia. and

enlarge all 1/32" dia. rigging wire location holes to 1/16" dia.

A cautious builder might reassemble to check that the fit and overall

alignment of these parts has not changed. Covering:

Cover the wings, struts, and tail surfaces with silk. Make up the

head-rest, landing lights and aileron horn fairings and cement in

position. Prick a pin hole in the fabric at each pre-drilled strut

or rigging wire locator hole or these will be lost under all the

coats of paint to come. Use your favorite method to finish the model.

Briefly, mine consists of four brushed clear coats, followed by

eight thinned-out sprayed filler coats, followed by at least six

thinned sprayed color coats with a wet or dry sanding thrown in

between every two or three coats. Then rub all parts with Aerogloss

Rubbing Compound. Wash thoroughly with soap and water and use home-made

stencils to spray the various marking and lettering details. These

stencils are a story in themselves. Letraset rub-on lettering is

used for the "Pitcairn Mailwing" rudder markings. Protect this rub-on

lettering with a clear dope overspray. Rub these marking and lettering

details with compound. Carefully cut out the cockpit opening and

use white glue to cement very thin leather padding around this opening

and on the headrest. We are now ready for final assembly and detailing.

Butter epoxy cement on all strut ends and slide all cabane

and interplane struts into the appropriate pre-drilled holes in

the top and bottom wings. The wings should be accurately aligned

automatically. Tape this assembly together and allow to dry overnight.

The following day all rigging wire ends can be buttered with epoxy

and slid into position. These too should dry overnight. Cement all

tail surfaces to the model. Make up and finish details like the

windshield, oil and gas filler caps, steps, aileron horns, vibration

dampeners, pitot tubes, position lights and wheels and cement or

solder these to the model. Dummy engine:

The Monogram Wright Cyclone Plastic Engine Kit PE52 was cannibalized

for the cylinder details. The cylinders were filed so that a 1/8"

dia. dowel pin could be centered in the cylinder for alignment and

reinforcing. Before joining the cylinder halves, pack each with

lead wool, About seven ounces of ballast can be packed in the nine

cylinders. Additional ballast can be installed in the cowling bottom.

The author's model required about 10 ounces of ballast for proper

balance for control-line flying. See plans for drawing of a simple

jig that can be bolted to the McCoy crankshaft to drill the 1/8"

dia. pilot holes for the cylinder dowel pins. After all pilot holes

are drilled, carefully cut away cowling at the base of each cylinder

until proper cylinder height is attained. The reverse side of the

afore-mentioned jig will accurately locate the height of each cylinder.

Install the push-rod and ignition harness details with plastic cement.

None of the Pactra enamels or plastic parts used in detailing the

cylinder details seem to have been effected by our model fuels.

Weight can be tolerated in the model's nose, so use plywood and

tubing where desirable for strength when making the exhaust collector

ring detail. Rather than have an unsightly needle valve

extension shaft cluttering up the engine and cowling details, the

entire flexible spring needle valve extension was snipped off. Needle

valve adjustments cannot be made with the cowling in place. Needle

valve adjustments must be made with the cowling removed prior to

moving to the flight circle. When a satisfactory adjustment has

been achieved, the cowling can be replaced and model is ready for

flight. The McCoy does not have a touchy needle valve setting so

this is a safe procedure. This procedure would not be practical

for all model engines. Recommended for those who love classic

biplanes, contest flying, and trophy collecting, the Mailwing is

hard to beat!

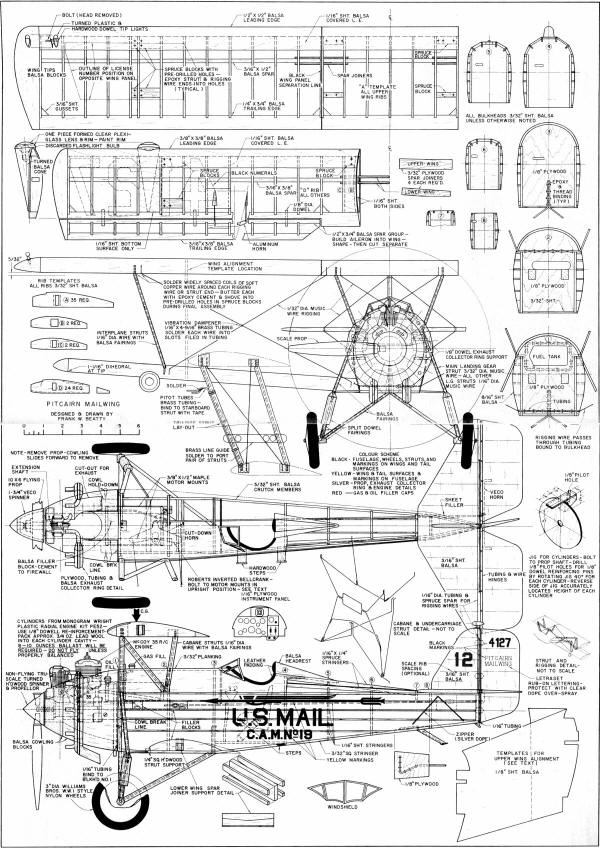

Pitcairin Mailwing Plans

<click for larger

version>

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted October 16, 2010

|