|

Website visitor Pat M. wrote to ask that I scan page 14 of this

Hi-Climber article that appeared in the December 1968 edition of

American Aircraft Modeler. I was glad to oblige, and while

at it, I processed the entire article. If the rubber-powered free

flight Hi-Climber interested Pat enough to build it, then chances

are someone else might like to as well. Hi-Climber is one in a long

series of "For the Tenderfoot" models promoting the entrance of

kids into the aeromodeling hobby.

Hi-Climber

Stu Richmond

Here's

a little cutie that really flies! It builds quickly and has almost

no critical dimensions. It's designed like a contest model. And

it flies like one! Plans are full size as they appear in this magazine. Here's

a little cutie that really flies! It builds quickly and has almost

no critical dimensions. It's designed like a contest model. And

it flies like one! Plans are full size as they appear in this magazine.

A few suggestions will help you get best results. Make sure you

use stiff; warp-free wood for the wings and tail parts. The propeller

and wheels, along with wire parts may be had from the local hobby

shop, or from some ready-to-fly models costing about 25c. Any plastic

prop near 5 1/2 inches in diameter will do. They are easy to find.

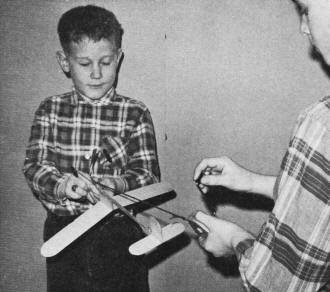

Study the pictures, tool list and materials list carefully before

you start. Putting maximum winds to the motor by stretch winding

will take some help from a friend, but flights will be about twice

as long if you use a mechanical winder, or a hand drill with a hook

in it. If you use a hand drill, put a slight bend in the hook where

it fits inside the drill and get it tightened well so it won't pull

out and cause an accident to your helper or the Hi-Climber .

Everything you need, both in materials and tools.

Razor saw is a help, but is not essential. Use of winder described

in article.

Parts have been cut out, landing gear bent to

shape. Important to note is simple method for putting the dihedral

in the wing.

You can add clay or chewing gum under a wingtip to control turns,

as well as to the nose (if model stalls) or tail (if model dives)

as necessary. All models built and shown in the pictures have required

no such weight additions. You can experiment by moistening lightly

the rear of the rudder and bending it to either side to control

the turns.

If you wish to experiment further after building your Hi-Climber,

follow step #20 and build one-half again bigger.

Step 1: Make patterns of all balsa parts by putting tracing paper

over the plans, or carbon paper and a sheet of white paper under

the plans. Trace the outlines and cut out the patterns.

1. Trace paper patterns with carbon paper. Trace

around patterns onto balsa sheet using ballpoint pen. Lines are

easily seen.

Step 2. With a ballpoint pen, trace around the patterns lightly

onto the balsa wood.

Step 3: Cut out the balsa parts using a ruler where needed to

cut straight edges.

Step 4: Sand all parts smooth and round except where parts join

together.

Step 5: Bend all wire parts to shape as shown on plans. Get help

if needed. Put on wheels.

Step 6: Glue wings together by putting one wing flat on the work

bench and raising the other tip up 2 1/2 inches. Use wax paper under

wing joint to prevent wing from being glued to bench. This forms

the proper dihedral angle and makes the Hi-Climber stable in the

air. Let this glued joint dry overnight, or at least until thoroughly

dry.

2. Prop one wing half up so tip is elevated 2

1/2" for dihedral. Cement halves together, using wax paper to prevent

sticking to work board. When picked up, be sure bottom is dry.

Step 7: Use a pin to make the hole for rear hook to fit bottom

of fuselage. Push rear hook into fuselage and wrap joint with thread.

Coat joint lightly with glue.

Step 8: Cut 1/2" length of metal tubing and glue it and spacer

block to bottom front of fuselage. Wrap with thread and coat heavily

with glue. If available, use epoxy glue on the nose rather than

white glue (such as Elmer's).

Step 9: Glue pylon onto fuselage and allow to dry. Make sure

high side is forward toward propeller.

3. Cement wing pylon to motorstick, pinning it

while cement hardens. Bind with thread and cement landing gear,

spacer and thrust tube in place. It does not pay to hurry your work.

Step 10: Put landing gear in fuselage, wrap with thread and coat

with glue.

Step 11: Glue stabilizer on top rear of fuselage. Use pins to

hold temporarily if needed.

Step 12: Glue rudder on either side of fuselage and against bottom

side of stabilizer.

Step 13: Glue wing on top of pylon. Use pins temporarily to hold

in place if needed. Make sure all parts line-up when viewed from

top, front and rear, and let the Hi-Climber dry thoroughly.

4. Bind and cement rear hook in position. Cement

fin to side of motorstick. Make sure it is on straight as cement

dries.

Step 14: Put propeller shaft through metal tubing, put on two

or three thrust washers, put on propeller and bend end of wire to

keep propeller on the shaft. Put one drop of oil on the washers

only.

Step 15: Lubricate the motor lightly with liquid hair shampoo

or with rubber lubricant and hook in position. (Or melt a little

margarine - not butter - in palm of hand.) Don't use oil on the

rubber. Measure 3 1/2" of 1/8" rubber, tie the ends together and

double the loop to make 4 strands.

Step 16: Wind about 50 turns into the motor (don't wind backward;

turn prop to right as you face front) and launch with a gentle push

into the wind with the nose pointed slightly up. If the model turns

too tightly to the right, moisten and turn the rear of the rudder

to the left (as viewed from the rear).

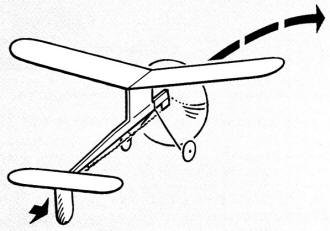

5. Stretch four-strand motor three times its

length to wind maximum of 250 turns with winder. "Walk" it in as

you wind.

Step 17: The model should circle to the right and climb high

under power. In the glide it should turn to the left or possibly

glide straight.

6. Bend trailing edge of fin in direction you

desire model to turn. Breathe on wood, and bend gently while doing

so.

Step 18: Maximum winds are put in by following the picture which

shows the model held upside down by the propeller while another

person stretches the motor three times its normal length and begins

winding while slowly advancing forward until normal motor length

is reached. With practice, 250 winds of the motor are possible every

time. This may only be 40 to 60 turns of your winder. See how many

winds each turn of the handle twists into the rubber motor.

Step 19: Fly the Hi-Climber away from trees and houses. It really

goes! Your schoolyard makes a fine flying field. Use the ballpoint

pen to put your name, address, and telephone number on the bottom

of the wing for safety.

Step 20: You may wish to make a larger Hi-Climber by using wood

twice as thick and making all parts half again larger than these

plans. Be sure to keep the angle between the top and bottom of the

pylon the same, as this is the only critical part.

Step 21: Happy flying on calm days. Be patient if wind is blowing.

An important part of building a flying model

is checking out the alignment of flying surfaces. Should not be

crooked - no warps!

The secret of long, long flights. Use an escapement

winder, or a drill with hook. Stretch rubber, wind and slowly walk

it in.

Hi-Climber Plans

Tools

Modeling knife or single-edge razor blade for cutting.

Ruler (a metal one would be best).

Very smooth sandpaper (#500 or #400 if possible).

Needle-nose pliers (for wire bending).

Small hacksaw (to cut tubing).

Pencil or ballpoint pen and carbon paper for tracing outline

of balsa parts onto balsa wood.

A few straight, steel pins.

A sheet of tracing paper or carbon paper.

Materials

One sheet 1/32 x 2 x 36" balsa. Must be stiff and flat. If not

available, use soft, flat 1/16 x 2 x 36".

One sheet 3/32 x 2 x 36" very hard balsa for fuselage; 1/8" thick

wood may be substituted.

One piece 0.030 or 0.045 piano wire for landing gear and hooks.

Two plastic wheels - about 1" in diameter.

One plastic propeller 5 1/2" diameter. 5" may be substituted

or a 6" propeller may be cut to 5 1/2".

One 2 or 3 washers - piece of 1/8" flat rubber 36" long for 4-strand

rubber motor.

One piece of 1/2" long metal tubing big enough for the 0.030

or 0.045 wire to fit through - can be cut from inside a ballpoint

pen.

Miscellaneous

Small amount of liquid hair shampoo for lubricating rubber motor

if model-type rubber lubricant isn't available.

A winder for the motor. Use a small hand drill with a hook in

the chuck, or use an R/C escapement winder.

Bottle of white glue.

Spool of thread.

Some help in bending the small wire parts if you aren't strong

enough.

Drop of oil for the 2 or 3 thrust washers.

Small piece of wax paper.

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted June 20, 2015

|