|

At the request of website visitor

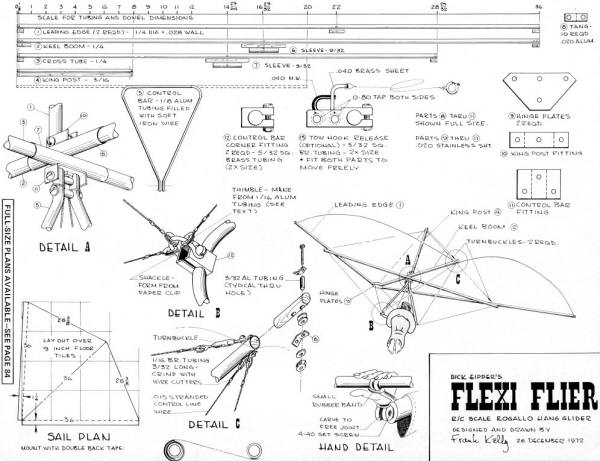

Guillermo A ., here is the article for Dick Eipper's Flexi-Flier

Rollago wing for R/C.

I electronically scanned the article, including images, from my purchased copy of the

April 1974 American Aircraft Modeler magazine, beginning on page 21. It is a 1/6-scale

version of the original that uses a GI Joe as the functional pilot. You might be able

to scale up the image below if you cannot find suitable plans for sale. The article was

written and plans drawn by Mr. Frank G. Kelly. All copyrights (if any) are hereby acknowledged.

See also The Insect free flight

model.

Flexi-Flier

Frank G. Kelly

Hang gliding is a new fad that is getting a great response on both coasts.

This distinctive scale model of a Rogallo wing glider is not only fun, but somehow

mysterious...

I first became aware of hang gliders in their

present form when I met Bill Moyes. While experimenting with a Rogallo wing as a potential

sidelight to his Australian water ski exhibitions, Bill discovered that he had broken

the altitude records for such things. Perhaps more significant, he found that the rogallo

wing ski-kite was a stable aircraft with the line slack or disconnected. The conventional

water ski-kite is in no way stable with a slack line. When Bill showed the movie of himself

jumping off the south rim of the Grand Canyon for a nine-min. flight to the river, I

knew I was hooked! On another occasion, he was towed to 10,000 ft. by an airplane, then

he released himself to glide back. I first became aware of hang gliders in their

present form when I met Bill Moyes. While experimenting with a Rogallo wing as a potential

sidelight to his Australian water ski exhibitions, Bill discovered that he had broken

the altitude records for such things. Perhaps more significant, he found that the rogallo

wing ski-kite was a stable aircraft with the line slack or disconnected. The conventional

water ski-kite is in no way stable with a slack line. When Bill showed the movie of himself

jumping off the south rim of the Grand Canyon for a nine-min. flight to the river, I

knew I was hooked! On another occasion, he was towed to 10,000 ft. by an airplane, then

he released himself to glide back.

During

the past year or so, hundreds of young people in the Los Angeles area have assembled

hang gliders, mostly the products of available hardware. Some are frightening creations

of bamboo, clothesline and garbage bags; others are very professional, made of the proper

kind of aluminum tubing, stainless steel cable, and rip-stop Dacron.

The one modeled here is a nearly exact 1/6 scale "Flexi-Flier," a popular contemporary

design by Dick Eipper. (If you want to build a full-size glider, get a set of plans from

him. DO NOT scale the model plans up. Parts and materials must be carefully selected

to avoid disaster!) Dave Cosgrove recently flew one (full-size) continuously for over

two hours in unusually favorable conditions near Palmdale!

The model, like the prototype, has a primitive but interesting and effective control

system. Pitching and turning is done by shifting the center of gravity by means of body

english. The pilot is suspended from a harness or swing seat, and the control bar provides

something to push against. The model is equipped with only two muscles, so the body is

suspended from a string leading under the arms and around the back. This worked out much

better than any of the more scale versions, and does not detract from the appearance.

It is interesting to note, if only for academic interest, that this control system is

effective at zero velocity. Ponder that during your next hammerhead stall.

|

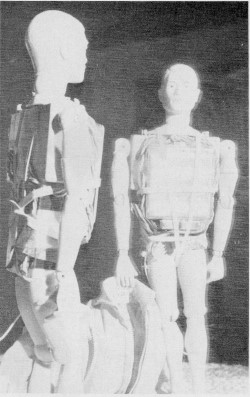

The mannequin

doll looks like a robot from science fiction as he admires his electronic innards in

a mirror. Even with KPS-10 size servos, there is adequate room inside the chest for a

complete flight package.

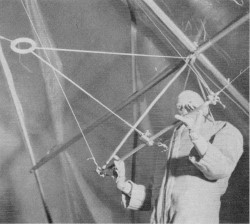

The doll in

position on his hang bar, amid a maze of rigging. Tow hook release bridle is shown here.

GI Joe is also available with a beard.

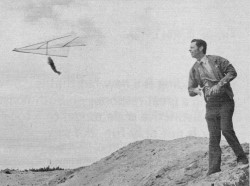

GI Joe takes

a hop aboard his Flexi-Flier. Note that the author holds the transmitter at a 45° angle,

a clever way to get elevon control. Watch that you don't detune the signal by accidentally

grounding the antenna with your hand. (Photo by Jerry Trager) |

Now ponder this: Two rotary servos operate the two arms. BOTH must move for each direction.

To pitch up, move BOTH arms forward to cause the body to move back. To pitch down, move

BOTH arms the other way. To turn right, move RIGHT arm back and LEFT arm forward (try

this while holding onto an imaginary towel bar).

To effect this complex set of motions, simply rotate the transmitter 450. This way

the aileron/elevator stick operates in a normal manner: "forward" moves both servos in

such a way that the model responds appropriately. Right stick turns right, etc., and

after just a few min., the controls feel quite natural. The same system could be used

for a V-tail airplane with NO extra linkage! The completed glider weighs just eight oz.;

after his extensive transplant, GI Joe weighs one lb.

The model didn't take long to assemble, but working with 0-80 screws involves some

fumbling, at best. I bought a 12-ft. length of 1/4" 2024-T3 aluminum tubing from a nearby

industrial supply house and settled for .028 wall thickness, rather than the more scale

.008. This was a good thing because it has to take some lumps. All the rest of the materials

are available at hobby shops or hardware stores, although finding long steel 0-80 screws

is something of a challenge. I made a drill jig out of a block of wood to help get the

little holes lined up properly.

The rest of the assembly is pretty much straightforward, with just a few exceptions.

The thimbles for the cable loops were made by threading bare copper wire through a piece

of 1/16 aluminum tubing. This was wrapped tightly around a long 4-40 screw and chucked

up in a drill motor. After filing half way through, the copper wire was removed and the

aluminum tubing sawed lengthwise with a modeling saw. This provided a handful of split

rings which resembled thimbles. The crimped ferrules were made of short bits of brass

tubing and crimped carefully with wire cutters. They're too small to crimp any other

way.

The control bar was made of 1/8" soft aluminum hobby tubing but, since strength was

necessary here, I selected a coat hanger which fit inside snugly. Music wire won't do

because it has to be drilled. Bending is easy with the wire inside.

Now that the hang glider is finished, you'll need a pilot. You've survived the jibes

about playing with little toy airplanes, so don't worry about playing with dolls again.

GI Joe is really a remarkable doll, beautifully articulated to move in all the proper

pl-aces. Pull an arm and a leg out of their sockets and snip the elastic holding them

on. Now saw through the torso at shoulder height. I did this on my table saw and found

it to be a curiously satisfying experience! My radio is a six-channel Kraft with KPS-10

servos and I found it necessary to discard GI Joe's hip sockets to make room for the

radio. With a two- or four-channel rig and KPS-12 servos, you might be able to retain

them, but it's not terribly important.

The two servos are taped together back-to-hack with the rotary shafts available for

attaching to the arms at the shoulders. The receiver can now be slipped between the bottom

mounting ears of the servos. This will locate the "brains" appropriately in the seat

of his pants. The flat battery pack will fit in the chest area. There's even room for

a switch under the battery in the general vicinity of the belly button. An S- shaped

wire hook can attach the head to the neck, and a 4-40 screw holds the legs together in

the upper thigh. A big rubber band holds the head and legs on like suspenders.

Drill out the wrist and elbow rivets and tap to accept 4-40 headless set screws. Carve

these joints until they move freely. Remove the rivet from the shoulder area of the upper

arm, and with a small soldering iron, fill in the area where the hook had been. The plastic

melts and fuses easily. When cool, cut a square hole to accept the servo output shaft

and screw on the arms. The flight suit can now be slipped over the pilot and when zipped,

he can't be distinguished from the original G I Joe. At this point, he is capable of

doing pushups to get in training. With the doll suspended from his armpits, and his hands

attached to the control bar with little rubber bands, the effect is absolutely captivating!

He swings around in a very realistic way.

Flight characteristics of the completed model were very realistic. it has about a

five-to-one glide path (remember, this is a glider, not a sailplane), and will flare

out very nicely for landing. Upon landing, the legs swing back gently and everything

is protected by the hang bar and rigging. Control capability is about the same as the

prototype, but I found that control could be overpowered by a strong updraft. A half-oz.

fishing sinker in the nose corrected this .

|

The mini-man does his thing. Control inputs should find the doll in each of the positions

shown:

Neutral

Left turn

Right turn

Up elevator

Down elevator.

It's a real marvel just to watch the mechanical man do tricks.

|

For the first few test flights, follow the technique used by the big ones. Find a

gentle slope which the prevailing wind blows toward and which has a loose sand surface.

start at the BOTTOM and, holding the model loosely at the top of the control bar, get

the feel of wind filling the sail and lifting the craft. Avoid touching the transmitter

antenna while holding it sideways because it will detune somewhat. Now make sure that

the sail is filled. Ease it gently straight into the wind and slightly downward. The

shove will cause the body to swing aft, giving it a tendency to pitch up a little.

After a few preliminary flights like this, you can start working your way up the h

ill. Notice that you haven't gotten into a dangerous situation yet. I f nothing works,

the worst thing that can happen is a mild jolt. The jump suit helps to keep sand out

of everything but doesn't prevent it. Finally, standing on the edge of the cliff, point

the hang glider directly into the wind and launch. It will gain altitude as, it moves

through the updraft, and the model can compete with a full-size manned hang glider on

absolutely equal terms. Sink rate, glide path, and directional control are all quite

comparable. The only problem is that everyone stops flying and crowds around to watch

when the model is there! If you become inured to the thrills of jumping off cliffs

in relative safety, you can add the tow hook release mechanism. Full "up" control pulls

the body back, and a string from the chest releases the catch. Full-size ones use a motorcycle

clutch cable. Towing is much more dangerous than cliff jumping, because the rigging can

be overstressed at high angles of attack. Higher speeds are attained, and it is possible

to get into a condition which cannot be corrected before impacting. Longer flights can

be sustained with the model though, and it makes for another interesting novelty. With

the tow hook, the model can be flown like a kite, towed aloft like a tow line glider,

launched with a long rubber band, towed from another RC craft (I'd like to try water

skis behind an RC boat, but GI Joe hasn't learned to swim yet), or dropped from a weather

balloon. My longest flight so far was from a manned hot air balloon at 5000 ft.

Braided fishing line is hollow like polypropylene water ski tow rope, and a loop can

be formed by threading an end back into the core. This bridle can be attached to the

control bar with a clove hitch. The towline has a drapery ring on the end, through which

the bridle is threaded. The ring can ride up and down the bridle freely and the pitching

moment induced by towing can be overcome. (If the towline is attached directly to the

control bar, the pitching moment will cause an immediate problem.) Upon release, the

bridle pulls through the ring and comes free. For the balloon launch, I melted a small

hole in the sail with a soldering iron and allowed the bridle loop to pull through at

release.

Under tow, the model has much more lateral control than in a free glide, due to the

way the different forces act and the moments associated with them. For this reason, the

kite technique is suggested for training purposes before attempting a tow. The ground

speed is initially zero. It is still possible for undampened oscillations to build up,

with hard dirt at both ends; so be prepared to release the instant a dangerous situation

develops. I f you can find another RC modeler willing to tow you up with his airplane,

the following precautions are important: attach the airplane tow hook , just behind the

cockpit, not at the tail.

Also, arrange for either end of the line to be released in an emergency. The tow plane

can use a spare channel or release with full left rudder. The glider can get airborne

in the first few t., then after a brief period of uncertainty, both can fly together.

Use a 50-ft. towline of four-lb. test nylon monofilament fishing line. It will stretch

a little, maintaining tension under load, and will break if overstressed. Teamwork is

required to pull this off. Gentle turns and a steady pull are important. The tow pilot

should throttle back a bit at release to avoid overstressing the glider rigging, but

also I the release will pitch the glider up, slowing down the tow plane. If the tow plane

turns down and left at release while the glider turns right and down, there will be less

of a tendency to interfere with one another.

If you like something different, try a hang glider. It is in no way an improvement

over more conventional aircraft, but it's fun and very easy to fly.

<click for larger version>

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted June 10, 2010

|