|

CO2

power for model airplanes gained a lot of popularity in the 1950s and throughout

the 1960s and then waned for some reason in the 1970s. The same trend was exhibited

in Jetex type engines. CO2 engines run off a cylinder of compressed carbon

dioxide gas, which were and still are readily available due to their use in air

rifles and pistols. A metal tube feeds the top of the engine cylinder where a metal

ball under pressure from the gas seals off the cylinder until the piston pushes

up on it. When the port opens, gas pressure forces the piston down to the point

where the gas is ejected at the exhaust port. Momentum from the propeller mass swings

the piston back to the top of the cylinder where it once again opens the ball valve

to start the cycle all over again. CO2 engines are very reliable and

easy to start since no ignition is required; however, the power-to-weight ratio

is fairly low. This 1962 American modeler magazine article presents plans, and

building and flying instructions for the "Fizz-Wizz."

See the "Push-Air

CO2-Powered Free-Flight" article from the February 1970 American

Aircraft Modeler and "CO2 Power

Is Coming Back" in the April 1969 American Aircraft Modeler. Here is a link

to my DP-03 CO2 motor.

Fizz-Wizz CO2-Powered model Airplane

Clever approach to real ''gas'' flight designing

utilizes Herkimer's CO-2 motor

By Aubrey Kochman

With Herkimer Tool & Model Works' CO2

engine again in production here's a plane designed expressly for this novel powerplant.

The challenge of CO2 designing is

as rewarding as the flights attainable with this engine. Shallow climbing turns

and graceful glides to perfect three-point landings bring back the realism so long

missing from free flight. And no noise to bother your neighbors!

The engine maker offers rough limits for a suitable model suggesting wing area

be between 115 and 165 square inches - our Fizz-Wizz has 135. Allowable "bare" model

weight of up to 5 ounces (less engine, metal fuel cartridge, cartridge holder, fuel

line tubing and propeller) in our opinion is too high. Structurally Fizz-Wizz has

more than adequate strength yet weighs in at a low 2 1/2 ounces (5 with engine and

accessories ready to fly).

Since air temperature plays a part in the power output of this engine hot performance

in cold weather is not to be expected. Fizz-Wizz is meant to be a realistic sport

model rather than a high performance contest flyer. Test flights indicated, however,

that under ideal conditions (3 to 5-mph winds, temperature above 80 degrees) Fizz-Wizz

with a little additional trimming should turn in some really respectable durations.

Before starting construction bear in mind the weight and temperature factors.

Cold weather operations call for the use of the lightest possible balsa. For those

who year-around enjoy warm temperatures some additional weight can be tolerated

... although it is not recommended.

If you use light balsa your model should balance as indicated. The cartridge

holder location and its angle keep the plane's C.G. from shifting as the cartridge

empties. There is slightly over an ounce difference between a full and an empty

cylinder.

Build the tail surfaces last as a means of balancing the model. Should the model

turn out nose heavy, use a heavier grade of balsa for the rudder or stabilizer or

eliminate the cutouts in either or both surfaces. For tail heaviness reverse the

procedure ... use very light balsa, make the cutouts larger and apply a minimum

amount of dope.

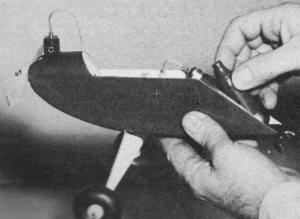

Loading a carbon dioxide fuel cartridge into Fizz-Wizz "power-pod"

is easy. Little chance of kinking or fracturing brass tube which carries gas to

C0-2 engine.

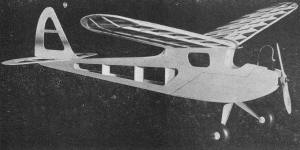

Attaching "power-pod" to fuselage. Full size working drawings

for Fizz-Wizz and Wizzo-Won are on Hobby Helpers' Group Plan # 362.

Fizz-Wizz frameworks.

Begin fuselage construction by cutting the two side pieces to shape; 4" wide

sheet balsa was used. With some careful planning both sides can be obtained from

a single sheet. Cut off the "power-pod" section and put the pieces aside where they

won't be used by mistake for formers. Cut out all formers and check that F1 through

F6 are all the same width ... F10 and F11 should also be of this same width. F1,

F2, F10 and F11 should also be set aside with "power-pod" sheets.

Assemble fuselage by cementing both sides to F5 and F6. Draw tail together, check

that fuselage is true along center line seen from the top. Cement tail together,

add remaining formers. Sheet cover top and bottom with grain running lengthwise

- moistening underside of top sheet with water between F6 and F7 will make this

bend possible. Water moisten outside of side pieces between F3 and F5 and apply

a coat of cement to the inside. As cement dries and with a little assistance on

your part the side sheets should assume their proper curve. Cement F3 in place,

trim side sheets so they butt together. Cement in appropriate lengths of 1/16" x

3/16" so half their width extends into the "power-pod" section. These strips act

as guides or keys to hold pod from shifting.

Before constructing the "power-pod" ... a word of explanation. The standard way

of loading a CO2 cartridge has been by pulling the holder down through

a hole in the fuselage bottom. Because the brass tubing through which the CO2 flows, although flexible, is quite stiff we felt

that the less bending required during the loading operation, the less chance there

would be for a kinked or fractured tube. Our "power-pod" eliminates these possibilities.

Since the lower end of the cartridge holder and thumbscrew extend outside the fuselage,

the cartridge may be replaced and plane assembled for flight without your having

to launch the model immediately.

Then, too, the cartridge can be pierced properly but the thumbscrew not backed

off enough so that gas flows to the engine. With cartridge completely enclosed,

it is necessary in such designs to disassemble the model to make the necessary adjustment.

This powerplant can operate clockwise or counter clockwise. Should the engine

fire up backwards you don't have to grab the prop with your hand, just stop it by

tightening the thumbscrew.

But enough of this ... back to construction. Make F10 by cementing the two pieces

together - with grain crossed at 90 degrees: Bend landing gear to shape as shown

on front view and bind it to F10 using strong thread and plenty of cement. Mounting

holes for engine should be drilled in F1 and mounting nuts secured to rear of former.

"Devcon" 2-ton epoxy glue does a good job of holding metal to wood, eliminating

the need of soldering the nuts to a metal plate. This glue takes overnight to harden.

An alternate method would be to mount the engine with small wood screws. With no

glow fuel to slosh around the engine compartment, and barring hard knocks, this

latter type mounting should prove adequate.

Make cartridge holder bed F11 and assemble "power-pod." Check that it mates properly

with the main fuselage. Water condensation forms on the outside of the spent cartridge

so waterproof the inside of the pod by applying at least 3 coats of clear dope.

The cartridge holder is bound to the 1/8" x 14" strip and F11 with strong thread

and cement. Lower end of holder was cemented to the bed using the 2-Ton glue.

Our wing, quite simple, is built in halves. It is assembled with a dihedral brace

and short lengths of spar stock to form the flat center section. The 1/16" sheet

tip outline should be level with the top spar. Light construction dictates that

all parts fit properly before cementing. Don't rely on cement to fill spaces between

poorly fitting parts. As cement dries and shrinks over a period of days, it could

pull misshapen parts out of alignment. And this type of built-in warp is the most

difficult to eliminate.

With construction completed go over entire framework with fine sandpaper, then

make sure all joints are strong. Apply a coat of clear dope to all framework and

allow to dry. Another light sanding may be necessary to take down the fuzz raised

by the dope.

To keep weight low entire model is covered with colored Jap tissue. Remove any

warps that occur during the covering-doping process. The stabilizer requires constant

vigil; should it show a tendency to bow or curl, pin it to a flat surface until

thoroughly dry - preferably overnight.

The tail surfaces may be cemented permanently in place or held to the fuselage

with light rubber bands. Latter makes flight trimming easier.

First flights should be on a calm day. Make test glides with the cartridge in

place. Stalls can be dampened out by adding some positive incidence to the stabilizer.

However, if more than 1/16" positive is required add weight to the nose instead.

For warm weather testing (above 75 degrees) don't launch the model until the

initial burst of power has subsided. Then if all goes well, subsequent full power

flights are okay.

Cold weather requires that the model be launched as quickly as possible, even

on first flights. Hold the model in launching position and have a helper flip the

prop so that no time is lost in the plane getting airborne. The CO2 engine

develops most power as soon as the prop is flipped and diminishes thereafter so

considerable altitude can be gained by this quick-launch method.

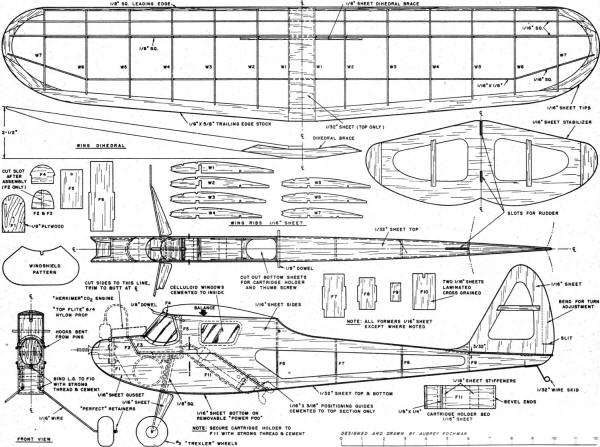

Fizz-Wizz CO2-Powered Model Airplane Plans

"Fizz-Wizz" Materials (Balsa unless otherwise noted)

Two pieces 1/16" x 4" x 36"; (1) 1/32" x 3" x 36"; (1) 1/16" x 3" x 36"; (2)

1/8" x 1/8" x 36"; (2) 1/16" x 1/16" x 36"; (1) 1/16" x 1/8" x 36"; (1) 1/8" x 5/8"

x 36" tapered trailing edge stock.

Also: 1/8" plywood; 1/8" dia. birch dowels; 1/16" dia. music wire; 1/32" dia.

music wire; 1 pr. #3 Trexler wheels; cement; clear dope; colored Jap tissue; celluloid.

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted January 15, 2024

(updated from original

post on 9/2/2013)

|