|

As is often - even

usually - the case, science is able to test and quantify theories and opinions to not

just determine which of competing views is most correct, but it also applies known principles

to improve upon the concepts. I have seen it done over and over again both within and

without the modeling realm. As early 1955, articles like this one have removed some of

the guesswork from amphibious model aircraft design. Similar articles have been written

using scientific methods to determine optimal parameters for various aspects of control

line and free flight. That is not to say results are necessarily settled science that

can never be challenged, improved, or disproved, but at least there is a documented set

of data for referencing when performing future works.

Facts About Flying Boats

By A. G. Lennon

Good technical articles like this one are few and for between. Believing that all

articles that really contribute to the art should be published, MAN is happy to print

this two-part discussion.

Ken Willard's Drake - spelled backward in the reflection - rides lightly

on the water. Half-A powered design, it was one of the most popular ever.

Many of us have seen otherwise well designed flying boats that just wouldn't take

off. They were great disappointments to their designers although, when-hand launched,

they flew well.

The obvious reason for their lack of success was, of course, that the water resistance

of the hull was so great that the motor was unable to accelerate the model to take-off

speed. Let's take a brief look at the causes of this resistance.

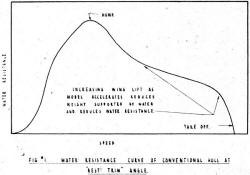

Early in the take-off run there is a period of high resistance called the "hump" (Fig.

1) which has to be overcome to get the model "on the step." This hump occurs as the ship

rises on the bottom surfaces and commences to plane on the water.

This hump resistance is dependent on two factors: the shape of the hull itself and

the beam loading. Let's consider beam loading. This is the weight of the model divided

by the beam (which is the widest point of the hull at or near the step). Beam loading

is similar to wing loading. The higher both are, the faster the model must move for successful

flight, and hence both demand more power. Correct beam loading is therefore a must.

Fig. 1 - Water resistance curve of conventional hull at "best trim"

angle.

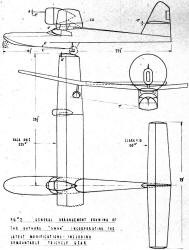

Fig. 2 - General arrangement drawing if the author's 'Swan' incorporating

the latest modifications - including demountable tricycle gear.

Let's assume the hull hump resistance and beam loadings are low enough to permit the

model to plane beyond the hump. Aerodynamic forces come into play. The model must then

continue to accelerate up to flying speed to take off. Hull bottoms all have some angle,

called the "angle of best trim," at which their planing resistance is lowest. However,

this angle may not be the same as the "free to trim" angle, or the angle at which the

hull tends to plane naturally, and hence the resistance at this latter angle is higher.

In full scale, the pilot, by using elevators after the hump has passed, can control this

angle and bring it close to the best trim angle for quickest take-off. Models, in contrast,

must have their wing and tail surfaces set at such an angle to the hull that, as speed

increases, these air surfaces will tend toward a level flight attitude and will hold

the hull at or near the best trim angle until take-off speed is obtained.

Another factor in hull design is Vee bottom, which is used in full scale practice

to reduce shock loads on the hull. Except at the bow, it has little place in model design

since it increases resistance and reduces planing efficiency. As the Vee cuts through

the water, it creates a lateral wave in each side which uses up some of the urgently

needed power. Full scale data indicates that a hull with a 20° Vee needs twice as

much planing area as a flat bottom, hence more beam. You have all skipped stones; were

you ever successful in skipping one that wasn't flat?

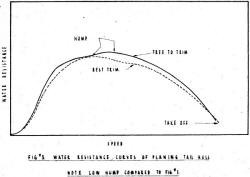

Fig. 3 - Water resistance curve of planing tail hull. Note low hump

compared to Fig 1.

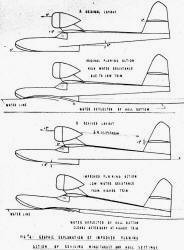

Fig. 4 - Graphic explanation of improved planing action by revising

wing-thrust and hull settings.

Porpoising is another take-off deterrent. If a model porpoises, it rocks back and

forth as it planes on the water. This rocking means that the trim angles of both hull

and wing are constantly changing and unless the amplitude occurs and the best trim angle

and is low, the may never take off. To go into the causes and cures of porpoising is

beyond the scope of this article, but the underwater shape of the hull has much to do

with it.

During late 1951 and early 1952 the author hopefully designed and constructed a model

flying boat based on the NACA developed planing tail hull formula (Fig. 2). This model

as first built weighed 17 oz. and was powered by an Arden .099 motor. It proved very

successful. Within a few feet the hull was planing smoothly on the forebody only, with

the afterbody clear of the water Under dead calm conditions it took consistently in less

than 15 ft. with no indication of porpoising.

During the summer of 1953 further tests were conducted leading toward development

of a radio controlled boat. By use of weights massed around the CG, the gross weight

was increased to 34 oz. The take-off run was longer, true, but after some adjustments,

the model got off smoothly and climbed still equipped with the reliable old Arden .099.

While this is certainly not a PAA Load carrying record, it highlights the efficiency

of the planing tail hull. For comparative purposes the wing loading of this model at

this 100 per cent overload was 15 oz. per square foot; beam loading was 8.5 oz. per inch

of beam and the power loading was 343 oz. per cubic inch of cylinder displacement. These

are quite respectable figures even for radio control.

Watching Harry Fosbury start Orwick .29 engine is Homer Snyder, who

made plane. Modified Flamingo kit (gone forever, boys!) is ROW beaut.

Lets examine the reasons for this model's success. Firstly, the planing tail hull

has a resistance, particularly at the hump Fig. 3) so that the model commenced planing

on the step promptly. Secondly as originally designed, the model had a moderate loading

of 4 oz. per inch of beam and wing loading of 7.75. oz. per square foot of wing area.

Thirdly, the planing surfaces were flat except near the bow, which, in to planing efficiently,

simplified construction considerably compared with a Vee bottom. Fourthly, the planing

tail hull is stable during the take-off run and does not porpoise. Resistance beyond

the hump is low and this hull very fortunately planes at a "free to trim" angle which

is very close to its angle of "best trim" and further offers considerable resistance

to any change from its "free to trim" angle (Fig. 3).

It was during these overload tests that the importance of the wing and tail angular

relationship to the hull was realized. As first designed, the model's forebody bottom

was 0° and the wing at 2° and while it took off successfully at 17 oz., it had

too long a take-off run at 34 oz. and tended to plane bow-low (Fig. 4A).

the angular set-up was altered so that the forebody bottom was at 4° to the horizontal

and the wing at 0°. The tailplane was adjusted accordingly to -2°. Thus, when

aerodynamic forces came into play, the hull rode with its bow higher, closer to the best

trim angle. The results were immediately apparent: take-off run was greatly reduced and

since this trim resulted in the hull being slightly bow-high in flight, landings were

smoother (Fig. 4B).

Specializing in flying boats for many years is C. D. Bowden of England,

who designed this "small" 5 ft. 6 in. job to be flown by radio control.

Summarizing: no aerodynamic forces should be permitted to oppose the natural tendency

of the planing tail hull to plane at the higher trim angles with low resistance, both

at the hump and beyond. Rather, they should accentuate this tendency.

Other important considerations were the thrustline position and angle and the effect

of the slipstream on the horizontal tailplane. It is an inherent feature of the flying

boat that the propeller must be mounted high enough to provide adequate clearance and

hence it exerts considerable nosing-down effect. The wing may be anywhere from the top

of the hull to the thrustline. However, the higher the wing, the longer the wing tip

float struts and the more vulnerable to damage they are. The lower the wing, the lower

the center of resistance and, consequently, the more nosing-down effect the propeller

thrust exerts. This resists the efforts of the hull to trim at the higher angles (around

8°) which have the lowest water resistance and acts as down thrust in flight. If the

thrust line is tilted upward - given "up-thrust" there will be a vertical component ahead

of the CG which offsets the nosing-down couple. Also, the slipstream acts at a negative

angle on the tailplane (Fig. 4) offering further "nose-up" effect, particularly at the

commencement of the take-off when the model is moving at slow speed but slipstream velocity

is high. Moderate up-thrust is therefore desirable.

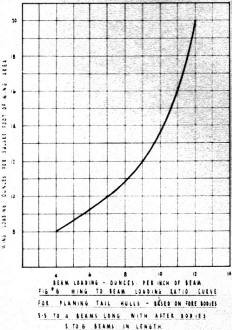

Fig. 6 - Wing to beam loading ratio curve for planing tail hulls -

based on forebodies 3.4 to 4 beams long with afterbodies 5 to 6 beams in length.

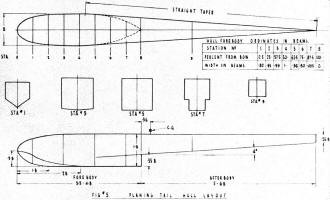

Fig. 5 - Planing tail layout.

We have the general layout of the hull as given in Fig. 5. Note the center of gravity

position. This location is necessary to obtain the low hump resistance, since it permits

the afterbody to carry its share of the weight at hump speed. You'll note that all dimensions

are given in terms of hull beam. This then becomes the basic, all important dimension.

We believe that beam loading should bear some relationship to wing loading. Take the

case of a model with a low wing loading and a proportionately high beam loading. This

model will fly at relatively low speed. However, at this low speed, the hull would not

be planing freely on the surface but would be dragging through the water. A successful

take-off under these conditions is unlikely.

Take the reverse of the above; high wing loading with a low beam loading. This condition

is more favorable to successful take-offs since the hull would be skipping along the

surface before sufficient speed is attained for flight. However, your model would be

penalized by the extra weight and drag of the wider hull. Of the two, nevertheless, a

low beam loading is more desirable.

The

graph in Fig. 6 gives wing and beam loading ratios based on the author's experience.

The range of wing loadings covers the practical limits for model design purposes. To

illustrate the application of these figures, assume we are designing a model whose estimated

weight is 36 oz., with a wing loading of 12 oz. per square foot of wing area. The corresponding

beam loading is 9 oz. per inch of beam. Hence, the beam would be: 36 oz. of weight over

9 oz. per inch of beam, 4 in. beam.

From this beam figure all other important dimensions of the hull bottom can be calculated.

The forebody and afterbody lengths can then be varied within the limits shown in Fig.

5 to provide a suitable tail moment arm after locating the wing in the correct relative

position to the CG. No tail extension should be necessary; simply locate the rudder and

stabilizer on the rear portion of the hull (Fig. 2).

You'll note that the diagram in Fig. 5 gives only the actual planing surfaces; the

shape of the upper portion of the hull is left co the reader's discretion. However, the

depth of the hull at the step should be approximately 1 beam and at the sternpost (end

of the afterbody) not less than 1/4 beam.

Suggested angular settings for the wing, tail and hull are as follows: Hull, +4°

(measured from forebody bottom); Wing, 0°; Tail, -2° to -3°; Up thrust, +2°.

These settings are given as starting points. The characteristics of your own design

will necessitate some changes in these angles, which can only be finalized by actual

test flights.

Posted September 17, 2016

|