|

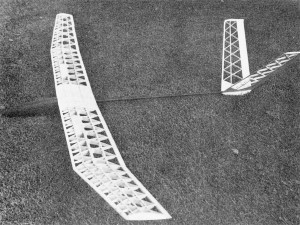

The Eclipse is a gigantic radio-controlled sailplane model with a 16-foot wingspan,

geodesic ribs construction, and "V" tail configuration. It is built up from

balsa, plywood, spruce, and a fiberglass tail boom. I remember first seeing

the model on the cover of the October 1974 issue of American Aircraft Modeler

magazine and really wanting to build one. Unfortunately, I was only 16

years old at the time and was barely able to afford control line models, let

alone a huge RC sailplane. Of course with the cost of balsa today, it is no more

affordable now as then. It probably takes four rolls of Monokote to cover! Here

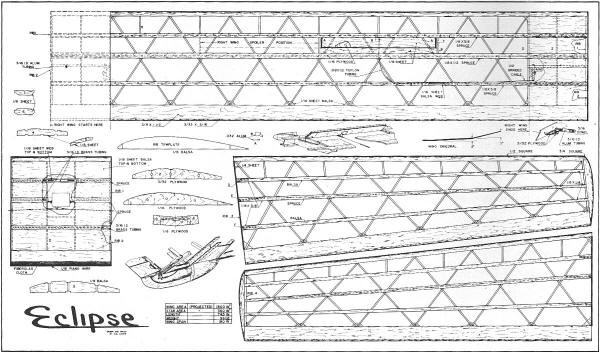

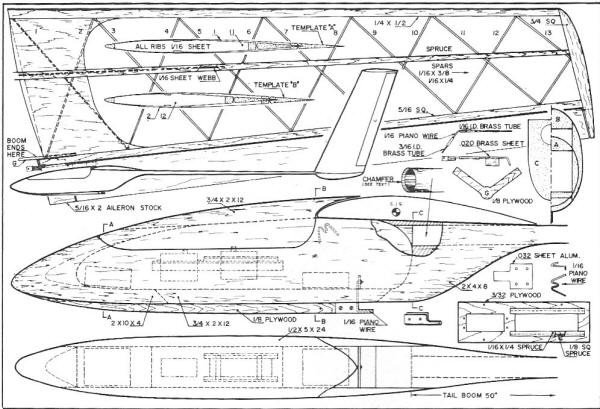

are plans for the Eclipse that I electronically scanned from my

purchased copy AAM. You might be able to scale up the image below

if you cannot find a source for ordering plans, because they do not seem to be

in the AMA Plans Service

inventory. Plans for this fine model were drawn

by Mr. Hal Cover. All copyrights (if any) are hereby acknowledged.

Eclipse R/C Sailplane

It casts a big shadow - with 16 feet of wing it should! Designed specifically

for extended duration, the Eclipse will ride thermals almost forever. It casts a big shadow - with 16 feet of wing it should! Designed specifically

for extended duration, the Eclipse will ride thermals almost forever.

By Hal Cover

Why a glider with a 180" span and the name Eclipse?

You will understand the first time it flies over your head with its gracefulness

and beauty. When it lands the size becomes very apparent, and you might even expect

a pilot to climb out looking for his glider trailer.

In comparing the performance of the Eclipse to a smaller version, interesting

performance variations appeared. First it flew in much higher winds than the smaller

one, even thought both had a an 8 oz./sq. ft. wing loading. Also, still air flight

times were as much as 50% better with the larger model. Probably the larger glider's

only weakness is that it is hard to pick up thermals at low altitude. The relatively

large tail and long tail moment contributes to its extremely stable flight characteristics.

In calm weather, flights of up to ten minutes have been made without aid of the

controls - in other words, free flight ... that includes the launch, too! If the

plane is allowed to fly straight, it will turn into lift by itself and stay in lift;

so let it find the lift for you. The spoilers are just effective enough to allow

a good controlled sink, with only up trim needed for proper attitude. This makes

spot landings a cinch.

The spoilers proved their worth on one flight where the plane rode a thermal

until it disappeared in the clouds. At this point, the spoilers were opened and

a large circle set in the controls. Without further action, the plane came down

safely ... but it took half an hour! This plane is big, and therefore can't be treated

like a small plywood and foam glider. If it gets way up in a thermal, use the spoilers

and up trim; don't dive it or spiral it in because the plane picks up speed fast

and it is not indestructible.

Locating a fiberglass tail boom for the Eclipse may pose a problem for prospective

builders. However, there are several approaches one can take. First, as the author

did, contact your local sporting goods store and have them recommend a fishing pole

manufacturer from whom you can make a selection.

The

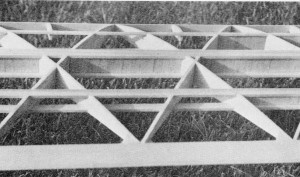

Eclipse is not, as it looks, a myriad of little pieces - it's a myriad of big pieces!

Using geodetic construction is the only way to build a 16-foot soarer with a reasonable

wing loading and good strength.

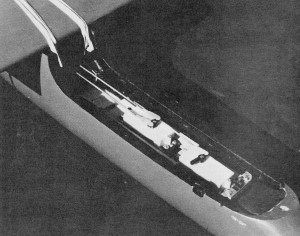

Detail shot of the wing structure shows spar webbing and warren truss ribs.

The modular wing center section houses the spoiler servo. The model disassembles

very quickly and stores easily with this arrangement.

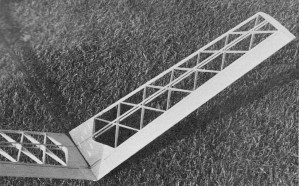

The V-tail is ultra-light, yet rugged. Minimizing drag on a 50" tail moment is

critical to maneuverability.

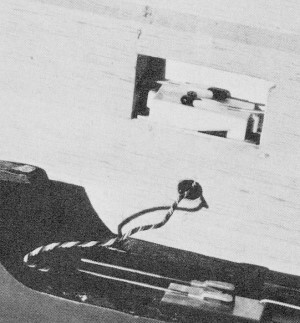

The back servo slides on a tray. The link to the forward servo is drilled right

into the servo case top. The slender pod decreases drag.

The author launches the mammoth beastie. The light wing loading makes hi-starts

practical.

If no manufacturer is readily available, perhaps the sporting goods store will

order one for you. The fiberglass rod should be about seven-nine ounces in weight,

eight to nine feet long and have a diameter of approximately 1 1/4" at the large

end. If you have difficulty with either of these approaches, contact me, c/o AAM,

and I'll supply you with a boom equivalent to the one used on the original Eclipse.

CONSTRUCTION

Building Tips: Always use spruce wherever shown - don't substitute

balsa. Web all areas indicated with hard balsa. The wing and stab structures require

a web for necessary structural properties.

The wing center section needs the 1/16" piano wire and fiberglass cloth covering

on the trailing edge; it is also recommended that the center section leading edge

and tip dihedral leading edge and trailing edge joints be fiberglassed. Use epoxy

and glass cloth as needed wherever wire hooks or tubing are installed.

Fuselage Construction: The fuselage is constructed from medium

balsa sheet and blocks. The sides are cut from 3/4 x 5 x 24" sheet, the nose block

is 9 x 2 x 4" and the rear fuse block is 5 x 2 x 8". 3/4 x 2 x 12" sheet is used

on the top and bottom. The tail boom size may vary depending upon what is available,

but the author's plane had a boom 50" long, 1" in diameter tapered to 1/2" diameter.

Cut out the blocks as shown on the plans. Glue the blocks, top and bottom sheet

to a side sheet. When dry, sand the edge of the unplanked side to obtain a good

flush joint. Glue the second side in place. Don't carve the fuselage to the correct

cross section until the tail boom is installed.

Tailboom Installation: The tail boom installation is critical

and should be done carefully. Place the fuselage upside down on a flat surface at

least six feet long. Block up the wing mount platform to the correct incidence angle,

as follows: The leading edge portion of the wing platform (at former B) should be

1" off the bench, and the trailing edge should be 1-9/16" off the bench. This will

position the wing platform on the fuselage at the correct incidence angle, with

the bench surface representing 0°.

In the next operation, the tailboom is going to be used as a drill. Carefully

sharpen the large end by chamfering the inside, as shown on the plans. Alignment

of the boom is achieved by blocking the small end of the boom to the same height

(1-9/16") above the table as the trailing edge portion of the fuselage-the boom

is now at 0° also. A straight line drawn on the bench may be used for boom alignment

left to right. With the fuselage and boom held in the proper position on the locating

blocks, push the boom into the block and drill by rotating with a fair amount of

pressure. Once the boom is into the block about one inch, the assembly may be removed

from the bench to finish the boring operation. This method may seem a bit strange,

but it gives an accurately aligned and tight fitting boom. Remove the boom from

the fuselage, take the plug out of the boom and reinstall with five-minute epoxy.

Carve the fuselage, using the templates shown for correct contour. Then cut out

the cockpit with a band saw or coping saw.

Cut the plywood skid from 1/8" plywood and bond to the fuselage. With the canopy

in place, cover the entire fuselage with one layer of one-ounce glass cloth. Put

an additional two layers on the nose and bottom of the fuselage, including the skid.

Remove the canopy and grind out the nose block as shown with a Moto-Tool or similar

device. The canopy can be held in place using several methods. The original was

held with a locating dowel in the front and snaps in the rear.

Servo Installation: The servo tray is made from 3/32" plywood.

The servo cutout size will depend on the servos used. The sliding servo is mounted

to two pieces of 3/32" plywood: 1/4" x servo width, plus 1/4". The guides for the

sliding servo are made by cementing 3/32" sq. hardwood to the strip on both sides,

1/8" away from the servo cutout. Glue a strip of 1/16 x 3/16" hardwood on top, with

the overlap to the servo side. When cementing this assembly, make sure the sliding

servo can move freely up and down the tray slide.

Towhook Installation: The towhook is made from soft .032 aluminum

and 1/16" wire. Bend the wire to shape and cut out the 1/4 x 2 x 5/8" plywood support.

Place the piano wire in the fuselage as shown. Slip the aluminum hook in place and

bolt to the skid using 4-40 bolts.

Wing Hook Installation: These are formed from 1/16" piano wire

and epoxied to the side of the fuselage, as shown. For additional strength, cover

them with two layers of glass cloth and epoxy.

Do as much finishing work as possible on the fuselage prior to stab installation,

because of the sheer size and awkwardness of the fuselage/stab assembly.

Stab Construction: Only half the stab is shown on the plans

but, since the airfoil is symmetrical, build two halves on the plan and flip one

over for the other half.

Using blocks, pin the leading edge and trailing edge in place 1/4" above the

plans at the center and 1/8" above at the tip. Cut out the ribs using the template

shown. Note that half of the ribs are solid, or uncut, and zigzag to the tips. These

should be installed first, followed by the installation of the cut ribs.

The method of obtaining the correct airfoil for all ribs is done as follows.

Mark the 1/16" sheet balsa with the required rib length and the 1/4" leading edge

and 5/16" trailing edge height. Use airfoil template "A" for the odd numbered ribs

1, 3, 5, etc., and template "B" for even numbered ribs. Lay the airfoil template

on the sheet balsa with its leading edge placed so that the top mark just shows.

Position the rear of the template in a similar manner, with the trailing edge mark

just showing, then cut the top airfoil. Repeat the operation for· the bottom surface.

Spar Installation: The tapered spruce stabilizer spars are installed

by marking the spar location and width (mark both sides) on the inner rib (1) and

the tip rib (13). Next lay an aluminum yardstick or straightedge over the front

marks, and cut a notch 1/16" deep in all ribs. Move the yardstick to the back marks

and notch again. Then cut out the material between the notches.

Turn over and repeat the operation on the bottom of the stab. Add the tip block

and glue the spruce spars in place, but make sure there are one or two inches extra

in the center for stab installation to the tail boom. Shape the LE and TE, then

sand all ribs.

Stab Installation: Fit the leading and trailing edge to the

boom carefully. Epoxy the dihedral brace (G) to the end of the boom, making sure

it aligns with the wing platform. The spars will lay over and under, as shown on

the plans, and should be butt jointed. When all items fit correctly, epoxy the stab

halves to the boom again making sure it aligns with the wing platform. The hinge

mechanism is bent to shape using 1/16" piano wire and 1/16" ID brass tubing. The

lower portion of the hinge or clevis attachment is made from 1/8" ID brass tubing

soldered to the wire and flattened. Drill a hole into the brass for the clevis.

The brass tubing portion of the hinge is epoxied to the rear spar. The fixed

portion of the 5/16 x 2" trailing edge is notched to fit over the tubing and wire.

The elevons can now be fitted and sanded, but not permanently attached (5/16 x 2"

light aileron stock works well for the elevons, if available).

Web and stab spars using hard 1/16" sheet with the grain vertical (the web should

run to half span), then sheet the top and bottom center section.

Push rods: Carve out the push rod holes as shown, and fabricate

the push-rods from 1/4" hard balsa 48" long, with threaded clevis wire on both ends.

The wire length is determined by the servo installation and hinge connection hole

location. When the linkage is installed and working, one should get ± 40° travel

out of each surface.

Tail Skid: Two 1/2 x 10 x 2" blocks can be cut to the shape

you desire. These are then hollowed out for both linkage clearance and weight. Next,

they are carefully fitted to the tailboom and glued in place. After final sanding,

the tail skid should be covered with a layer of fiberglass cloth and resin.

Wing Construction-Inner Panels: The 28 inner panel wing ribs

are cut from medium 1/8" sheet, using the diagonal rib template. The false ribs

(5) are also cut from the same medium 1/8" sheet. All inner panel spars are spruce,

with 1/8 x 1/2" used for the center spar, and 1/8 x 3/8" used for the front and

back spars. Medium hard balsa wood should be selected for the leading edge and trailing

edge. Before the wing is constructed, add 3/32 x 3/16" spruce to the back of the

trailing edge. This strip is very effective protection against dings and cuts when

building and flying.

Cut two number 3 ribs from 1/8" hard sheet balsa. Do not cut the ribs apart at

each spar location until the spar has been installed in. a later building step.

Pin the LE and TE down over the plans. Block up the plywood ribs 1/16" when installing

to allow for the bottom sheet. Glue the geodetic ribs in place, noting which are

continuous and which are cut in half when forming the geodetic structure. When the

basic structure is dry, remove from the plans and build other inner panel in a similar

manner.

Wing Tips: The tips are built using medium balsa for the LE

and TE, and medium hard balsa for the front and back spars. The center spar is cut

from 1/8 x 3/8" spruce.

Cut the wing tip ribs out of light 1/8" sheet balsa using the diagonal rib template.

Use the same procedure for these ribs as used on the stabilizer ribs. Some ribs

will be slightly thicker than necessary and must be sanded to the correct contour

after the spars have been installed. The actual construction of the tips is done

in the same manner as the inner panels.

Wing Dihedral: Pin or weight the inner panel down to the bench

and block the tips up with 7" of dihedral. Sand carefully to fit, then glue together.

Add rib 3 (still not cut apart). When dry, remove from the bench and carefully mark

the spar locations on the tip rib 4. To notch out for the inner panel spars, lay

an aluminum straightedge over the ribs, using the plywood rib notches and dihedral

rib 3 notches for position reference. Cut a 1/8" deep notch in each rib-repeat this

step until all spars are notched at both the front and back edges. Trim out all

notches to 1/8" deep. Notch the tip ribs in a similar manner, except use the marks

on rib 4, and the notches of rib 3 for spar location reference.

The spars should be glued in place 1/16" above the plywood ribs to allow for

sheeting and be flush with all balsa ribs. Add the lower spars first. Cut out the

spaces between rib 3 sections so that the 1/8" plywood dihedral braces D, E and

F, can be installed. Next add the upper spars. When the spars are added to the tips

you will find that some ribs are too high. These should be notched deep enough to

allow the spars to be flush with the top of the lower or thinner ribs. Use a straightedge

on top of the spars to make sure it is flat and not irregular due to incorrect spar

notch depth. The center spar is webbed with hard 1/16" sheet balsa out to the center

of the tips. The front and rear spars are webbed to the tip dihedral break. The

grain of the web must run vertically if it is to be effective.

Spoilers: Laminate two pieces of 1 x 12 x 1/6" plywood to two

pieces of soft 1/8 x 1 x 12" sheet balsa. Epoxy the hinges and horn to the plywood.

Add the 3/16" ID aluminum tubing to the center ribs (2) and glue the 3/32" plywood

bellcrank and mount in position. Set the spoiler in place and epoxy the hinge to

rib 6, then glue rib 7 in place. Rib 7 acts as a stop, to locate the spoiler in

the proper position when closed. Sand the upper surface of the spoiler (1/8" sheet)

to match the upper airfoil contour. Epoxy the Teflon or vinyl tubing in place as

shown. Slide the 0.012 braided cable through the tubing and attach it to the spoiler

horn and bellcrank. Then add a light tension spring to the spoiler, as shown, to

hold the spoiler closed.

The action for opening the spoiler is quite simple. The servo, mounted on its

side in the center section, pushes two rods out, which press against one end of

a 3/16" dowel located inside the aluminum tubing of the inner wing panels. The dowel

pushes against the bell crank, which pulls on the cable and opens the spoiler. This

system requires no actual center section-to-wing hookup. The worst problem that

can occur in flight is, if the wings slide out on the rods a bit, the spoilers will

only partially open when activated.

Wing Center Section: Slide four of the number 2 ribs on four

brass tubes cut to the correct length (the center tube is two pieces, to allow for

the servo mounting in the middle). Place on the plan and block up 1/16" to allow

for sheeting. Coat all rib ends with glue and place the LE and TE in position. Hold

them in place with pins or weights. When dry, remove from the plans and add all

the spruce spars. Web the spars with 1/16" hard wood or plywood. Next install the

servo and drill holes in each rib to allow the clevis rod to pass through and mate

with the inner panel aluminum tubing/spoiler assembly. The entire top and bottom

is sheeted with firm 1/16" sheet with only a cutout in the bottom sheet for servo

access.

Wing Assembly: Position the brass tubes into the inner wing

panels. Check alignment with the center section tubes. If all aligns, epoxy the

tubes in place. Block off the end of each tube with a 1/2 x1" piece of plywood,

so that the tubing cannot be pushed into the wing. The tubes should then be webbed

top and bottom with 1/16" spruce or plywood.

A beautiful study in sailplane aesthetics, the Eclipse is elegant and spirited

in flight.

Assemble the wing, using six rods of piano wire 3/16" dia. approximately 7" long.

Check out the spoiler mechanism and, if all works well, sheet the top and bottom

of the inner panels with firm 1/16" sheet. Shape the leading edge and ribs to remove

any burrs or rough spots on the wing surfaces.

Covering: The covering is accomplished with the help of the

Bank of America and four rolls of MonoKote. All surfaces are covered with normal

MonoKote procedures. Cover movable surfaces before installation. The original Eclipse

was covered with red MonoKote on the top surfaces and orange MonoKote on the bottom.

Chrome mylar trim is used on the leading edge for visibility and directional reference.

You will be surprised how effective these strips are when the plane is a dot in

the sky - and with this plane, that's high!

Flying: Balance the plane to obtain a flat, straight glide with

all trim adjustments set in neutral. Use the CG shown on the plans for a reference.

Balance may take as much as 12 ounces of lead, depending on your construction weight

and RC gear.

With this flight setup, you will find full right or left trim, along with full

up trim, will give you a nice circle for hands-off thermal soaring.

Good luck with your Eclipse and, if you have half as much pleasure from your

plane as I have, you will agree that the work building it was well worth it.

<click

for larger version>

<click

for larger version>

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted August 14, 2024

(updated from original

post on 3/18/2012)

|