|

Here is another round of nifty model

airplane building ideas, aka "Sketchbook," submitted by readers of the Academy of Model

Aviation's (AMA's) American Modeler magazine. I'm not too keen on the "rubber

mold" idea of using a thin layer of silicon rubber, trimmed to the design outline with

a razor knife - especially over an open wing bay or between fuselage longerons. Controlling

the depth of the cut is tricky, especially in a layer of silicon that is not of uniform

thickness. Mr. Itter must have a steady hand. Using a length of brass tubing with

the end filed or sanded to a sharp edge is a handy trick for cutting holes I have used

many times over the years - probably after having first seen it in American Aircraft

Modeler, R/C Modeler, Flying Models, or Model Airplane News.

Sketchbook

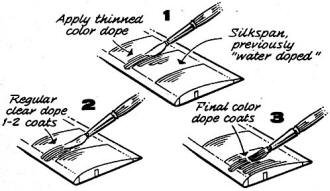

(left) Claiming a more uniform finish, Bill Itter,

Stamford, Conn., applies thinned color dope to Silkspan prior to regular doping. Final

color coats follow. Especially helpful with light colors. (left) Claiming a more uniform finish, Bill Itter,

Stamford, Conn., applies thinned color dope to Silkspan prior to regular doping. Final

color coats follow. Especially helpful with light colors.

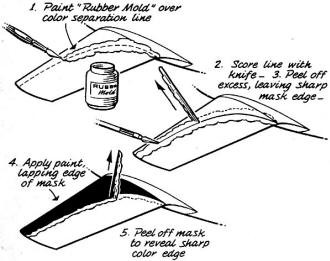

(right) Jess Brewer, Winter Haven, Florida, discovered

"Rubber Mold" in art supply store; used it successfully for easy masking on model surfaces

for two-color finishes. Use two coats, he advises. (right) Jess Brewer, Winter Haven, Florida, discovered

"Rubber Mold" in art supply store; used it successfully for easy masking on model surfaces

for two-color finishes. Use two coats, he advises.

(left) Effective modelers' punch-drill is gadget

of G. A. Wilson, Walpole, Mass. Brass tube has serrated edge, is spun between fingers.

Cuts cleanly through balsa and thin plywood. (left) Effective modelers' punch-drill is gadget

of G. A. Wilson, Walpole, Mass. Brass tube has serrated edge, is spun between fingers.

Cuts cleanly through balsa and thin plywood.

(right) Improvement on radial mount previously

printed is this idea by Roman Szalek, LaSalle, Ill. Plywood reinforcements provide landing

gear grooves; mount flanges secure wire in place. (right) Improvement on radial mount previously

printed is this idea by Roman Szalek, LaSalle, Ill. Plywood reinforcements provide landing

gear grooves; mount flanges secure wire in place.

Got a new idea for construction, adjustment or operation of model planes, boats or

R/c? "AM" pays $10 for each "hint & kink" used. Send rough sketch and description

to Sketchbook, c/o American Modeler, 575 Madison Ave., New York 22. N. Y. Please note

that because of the very large number of submissions, none can be returned to the sender.

Posted September 22, 2018

|