|

It would be difficult to find a more perfect aerobatic scale biplane

for control line flying than the Waco Taper Wing (WTW). Its solid

frame, near-zero dihedral in both wings, and nearly symmetrical

airfoil is just what the serious stunt flyer needs. Construction

is standard built-up stick and sheet balsa framing members and Silkspan

and dope covering. Today, you might choose to cover the Taper Wing

Waco with Monokote, or even

Coverite 21st Century Fabric if you want an authentic fabric

look that is still iron-on. Originally designed for a .30-size glow

engine, the model could easily be converted to electric power.

Taper Wing Waco

By Floyd R. Guyton

A grand' old bipe, favorite of many a famous stunt .pilot,

returns as a slick control line flying scale powered with .29 to

.32 engines

If you were old enough to tie your own shoelaces when "Lucky

Lindy" made history in 1927, then you might recall the era of the

stunt biplane, exemplified by the Waco Taper Wing.

Even if you can't remember "the good old days" you can see what

a fine model this Waco is for stunting or for real detailed scale

flying. With no apparent dihedral, an almost-symmetrical airfoil,

and with its landing gear well forward, the WTW makes. an excellent

subject for U/C work. The Taper Wing, with its generally clean shape

and efficient tapered wings, was a great improvement over its predecessor,

the Waco 10.

Two models made by the author logged more than 150 flights, with

one model taking stunt and scale honors in the same contest. The

hot rock stunters can go easy on the super-details for a lighter,

more maneuverable ship. But loading the ship down with wheel pants,

cowl ring and such will not take the edge off its stunting ability

- it will still turn inside the other scale jobs and match some

of the flying barn doors in intricate acrobatics.

Testing should be done with the usual balloon type wheels, the

home-made scale type being saved for competition work. If wheel

pants are used, stock wheels can be employed, as they will not "show"

and a lot of work can be saved. Remember, with or without cowl and

pants, the job is still true to scale, as the prototypes were flown

both ways.

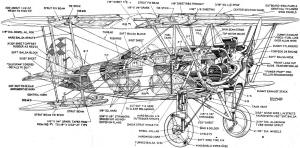

Now let's get a-building. Grab some 1/8" square balsa, but hard.

The basic framework can be tossed together as per the side view.

Allow the longerons to project slightly forward of Station 3, as

they fit into notches in F3. Once all the required cross braces

and diagonals are in place, allow the cement ample time to dry thoroughly

and remove from workbench. Building both side frames at once insures

exact duplication, so play safe and do it that way.

Use a thin razor blade to separate the two frames and start assembly

in the orthodox manner, tail-first. Work for ward carefully, checking

each frame for squareness as you go along. Note that the cross pieces

at Station 3 are not equal, due to slant. If desired, diagonals

at each station will help rigidity immensely, especially at Stations

5, 6, and 7. Hard 1/16" x 1/8" balsa is fine for this; it can be

left in permanently if not in the way of the push-rod, or cut out

when the fuselage is partly covered and has greater torsional rigidity.

The plywood bulkheads F3 and F4 can be slipped in place now and

cemented securely. Be sure to get all the holes cut out or drilled

through F3 and F4 before assembly.

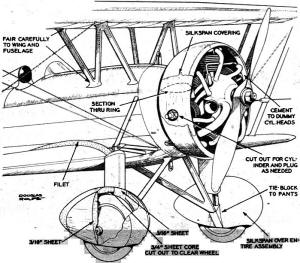

The engine bearers can be slipped in place and cemented next.

Note that the upper bearer is longer - extending beyond the rear

of F4 to provide mounting space for the bell crank. The bottom of

this bearer is cut away to provide a horizontal surface for mounting

aforesaid bellcrank which, incidentally, protrudes through F4 (see

gourd-shaped hole made for this). Note that the push-rod arm of

the bellcrank is bent down somewhat to clear the upper cross-brace

at Station 4. Try to assemble as much of the control system as possible

in the early stages of construction, as hooking up the pushrod to

the bellcrank and other similar jobs are difficult once the stringers

and covering have been practically done. This applies to the lead-out

wires also.

The unorthodox position of the engine, with one engine bearer

under the crankcase lug and the opposite bearer over the lug may

seem unnecessarily complicated, but it is a fine way of hiding the

K&B .29 and providing space for a fuel tank of moderate size,

mounted in an ideal position. The usual upright position of a .29

in this ship necessitates running the engine bearers right through

that area where the tank should be - level with the needle valve.

However, for some compact engines like the Forster F-29 it shouldn't

be much trouble to "pad" the front of F2 with a slab of 3/8" plywood

for a radial type mounting for even greater latitude in positioning

the tank. In the event that you rework the nose section for radial

mounting, remember to beef up the construction enough to compensate

for the absence of engine bearers. And leave the bellcrank where

it is, regardless of what rework you do in other departments.

After bending the landing gear to shape, install as follows:

front (axle) strut, fastens to rear of F3 with spade. or "J" bolts,

rear struts are wrapped and soldered to front strut near axle, with

rear upper ends landing on the front bottom face of F4 (note holes

to receive same). Try to make all bends possible before installation

and remember that the true lengths are given in the front view and

cannot be measured or "lifted" from the full-size plans.

It won't hurt for the L.G. assembly to be installed so that there

is a little tension between the rear struts and F4 to keep the strut

ends in their respective holes. Allow the strut ends to project

about 1/4" past the rear face of F4.

The tailskid is bent up as per the plans and "sewn" to the 1/16"

plywood mount with fine wire. Cement liberally. Then cement assembly

to top surfaces of the bottom longerons. A vertical brace can be

added for safety's sake at the rear of the mount, but be sure that

it is not in the way of the horn or pushrod. The fuel tank should

be installed now, generously cemented and braced against shifting.

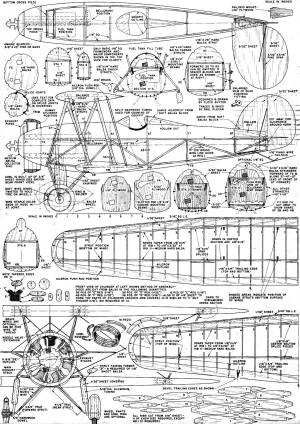

The top formers 1T, 2T, 3T, etc., are now added and the stringers

slipped into the notches. Hard. 3/32" x 3/16" stringers are used

forward of F3 and on the top formers 3T, 4T, and 5T, where 1/32"

sheet balsa covering is to be applied, with 1/16" x 1/8" hard balsa

stringers used elsewhere. The 3/32" x 3/16" stringers butt up against

the front of 6T,with the 1/16" x 1/8" stringers being used from

6T of the tail post.

Although the area over the stabilizer was sheet-covered in the

original model, many will prefer the simpler expedient of using

a carved block, hollowed out for lightness.

This block can be spot-cemented and carved after the horizontal

tail surfaces have been installed. Once hollowed, it can be cemented

on permanently, followed by the rudder surfaces. Nothing unusual

about the tail construction - just plain 3/32" sheet. But do cut

out clearance for back-travel of the elevator horn. Note the simple

but compact pushrod fitting for the elevator horn.

Once the balance of formers and stringers are in place, covering

may be started. The 1/32" sheeted areas are applied in the following

sequence: first, a narrow strip of 1/32" sheet is trimmed to fit

between the top stringer and the stringer adjacent to it. Rubber

bands around the fuselage should hold it snug against formers and

stringers after the cement is applied to hold the sheet against

the top stringer. The other edge, along the next stringer, is left

loose, so another sheet can be slipped under the .rubber bands.

A razor held against the edge of the first sheet can cut and duplicate

the trimmed edge to the underlying sheet. Of course, the rubber

bands will have to be shifted to avoid cutting them.

Thus, when a sheet is trimmed on both edges, only the high edge

is cemented in place - the low edge forms a pattern for the adjacent

sheet. And so the covering progresses downward from the top stringer

till all the side is done. If the wood you have on hand is "uncooperative,"

you can coax it along to fit any compound curves by dampening the

exterior face and by using thin cement on the interior surface to

draw it around. Put aside just long enough for the curve to "set"

slightly, then install.

It will be much simpler to do the work in short longitudinal

sections - in other words, don't attempt to cover too long a stretch.

Short pieces, from former to former will go on easiest.

Complete building details are available on the full-size plans.

Waco Taper Wing Plans

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted March 6, 2015

|