|

This wide view of the Martin (now part of the Lockheed-Martin conglomerate)

model shop brings back memories of when I worked as an electronics technician

at the Westinghouse Oceanic Division in Annapolis, Maryland. We had a bunch

of guy in lab jackets sitting around at benches with out machinist's tool

boxes open. Most people had the Gerstner, Craftsman, or Union brand (mine

was Craftsman). Serious tool accumulators had the large model with the big

drawer in the middle for hold a machinist's reference manual (my shop did

electronics assembly and prototype building, so we kept other things in

ours). As with so many other things, I eventually sold my toolbox, but,

fortunately, there is almost nothing you cannot buy on eBay, so a couple

years ago I bought one like what I had before. You can see it by clicking

on the above thumbnail if you are interested. I'm not sure how much model

making is done anymore since computer-aided design (CAD) is so dominant

in design organizations nowadays.

Modelers at Work in Aviation, Space and Electronics

|

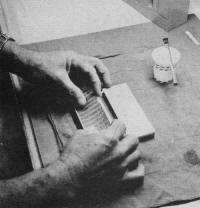

General view of the Wood and Plastics area of Martin Orlando's

Model Engineering shop with finished miniatures of several missiles.

All photos made at Florida plant.

|

|

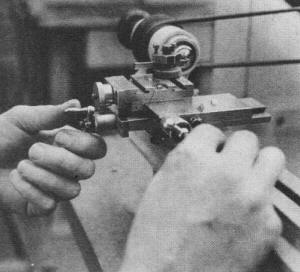

A jeweler's lathe is employed to make miniature turnings such

as knobs and controls for a scale copy of the "RACEP" console.

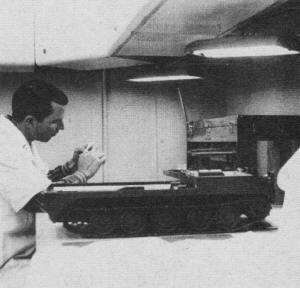

Laboratory technician works on a brass part for an 1/8-size Pershing

missile tracked vehicle.

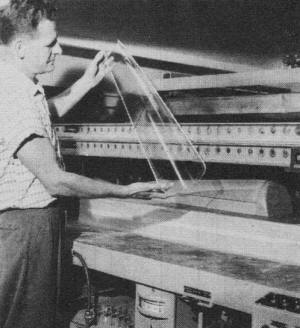

A vacuum-formed section of a scale Pershing nose. Master is of

maple; Plexiglas is clear 1/8" thick.

|

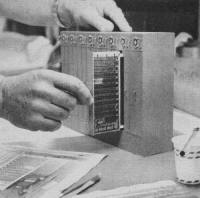

Left: These pix show how a detailed photograph of

an electronic chassis rack is used to simulate the set-up in a scale model.

Photo is cut to size, then bonded to plexiglass panel; technique saves many

hours of work - certainly is authentic!

Behind

every missile system in the nation's defense arsenal are extensive periods

of development. And, strongly involved in the development phases are highly

professional model shops which build everything from large, full-scale prototype

missiles to tiny replicas of complex electronic circuitry. Behind

every missile system in the nation's defense arsenal are extensive periods

of development. And, strongly involved in the development phases are highly

professional model shops which build everything from large, full-scale prototype

missiles to tiny replicas of complex electronic circuitry.

One such model shop is in busy operation at the Martin Company's Orlando,

Fla., Division. This Martin Division builds the Pershing and Lacrosse surface-to-surface

missiles, the Bullpup air-to-surface missile, and Missile Master and "Birdie"

electronic air defense systems and the "Racep" electronic communications

system. Also, Martin Orlando is working on the "Tow" anti-tank missile and

numerous advanced space and weapons programs.

Thus, the press of work is consistently heavy for the 96-man Model Engineering

Section headed by E. J. Guard. Current projects, for example, include constructing

a full-size ground effects machine American Modeler which actually will

be the test bed for Martin studies in this field and building a series of

prototype missiles which will be launched for testing on a highly secret

Martin project.

Much of the work, however, is along the lines familiar to modelers the

world over. Scale models, in varying degrees of complexity, are important

parts of training programs as well as being valuable in working out engineering

and operational system problems. Martin's modelers build exact, totally

operable models of the company's missiles. They are perfect copies of systems

launched from Cape Canaveral and elsewhere.

Special building techniques, tools and highly skilled personnel make

the results of Martin's shop enviable. The shop itself is divided into four

sections: (1) Wood and Plastics; (2) Precision Machine; (3) Sheet Metal;

(4) Electronics:

The accompanying photographs show products of those techniques and tools.

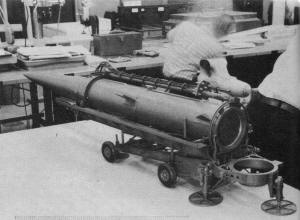

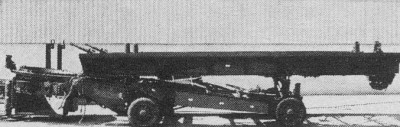

Fully operable 1/8-size Pershing Transporter Erector

Launcher and the real item are seen in photos above. Model is so finely

detailed each operation of the big one can be duplicated; model is mostly

brass with "britannia" metal castings.

Posted September 7, 2014

|