|

The Douglas DC−3

(C−47 was the military version designation) has always been my favorite twin

engined commercial airplane. Its nickname of "Gooney Bird" amongst troops is

undeserved IMHO. The DC−3 is credited with launching the commercial airline

industry, and its C−47 version was listed by Dwight D. Eisenhower as being on

the most important tools for winning World War II. Edward F. Burton, Chief

Engineer at Douglas Aircraft Company, runs through the evolution of the DC−3 and

it predecessors and descendants in this December 1945 issue of Flying Age

magazine. December of 1935 marked the maiden flight of the DC−2, was was a

direct follow-on the the DC−2. A single DC−4 (4 engines) was built and delivered

to Japan. Then a DC−5

was built (high-wing version of the DC−3) but never went into production. The

4-engine DC−6 entered commercial

service in 1946, followed by the very popular

DC−7. A coaxial,

counter-rotating pusher prop model

DC−8 (not to be confused with the 4-engine

commercial DC−8 jet) never made it

off the drawing board. The next iteration was the C−54, which was a huge success

with four engines and tricycle landing gear. It became the first dedicated

presidential aircraft (aka

Air Force One). Finally (at the time of this "Build Me a Plane" article),

the C−74

Globemaster made its debut in September of 1945, right after World War II

ended.

Build Me a Plane

The power and the beauty of the Globemaster has a history of

patient endeavor and a series of experimental predecessors that paved its way.

It takes years of patient, skilled, heart-breaking man-hours to evolve a plane

that will do its job.

By Edward F. Burton

Chief Eng., Douglas Aircraft Co.

No airplane is ready-to-wear. They're all custom-made to some pretty exacting

requirements.

When you buy your ticket, walk up the gangway and say "hello" to the hostess,

you take your airplane for granted. It will fly to the precise destination you want

on a schedule neatly predicted. There will be a seat that can he inclined at a proper

napping angle. There will be ventilators that you will manipulate without a second

glance. There will be ash trays at your hand.

But most thoroughly taken for granted of all the airplane's many qualities is

that it will fly. And what is more important it will have the flying characteristics

most needed on the particular route you must take. In short, it fits precisely.

And the story behind that perfect fit is one of meticulous planning, of countless

highly skilled man-hours, of tests, failures and a success that is cumulative, growing

out of all the previous successes and failures in the business.

The airlines know, or think they know, exactly what the passenger and the cargo

shipper want on any particular hop. And they come to the aircraft companies with

a list of requirements. We must have so much room for cargo, they say. We must have

so many passengers, and this percentage of them must have berths. We must be able

to feed them. The crew must have quarters. Then, it will have to go at this speed,

have that cruising range, be able to fly in weather like this or that. There's what

we want; they conclude, go build us a plane to do the job cut out for it.

And the aircraft companies examine the list of requirements, go over all the

blueprints of previous planes, acknowledging this factor and deciding to reject

that one.

A case in point is the DC-8, Douglas' latest model which with its dual props

in tandem right behind the tail, promises to create a stir in engineering circles

and in air passenger circles. But it is really a product of all that went before

it. It is the final phase in a development that began with the DC-1 back in 1933.

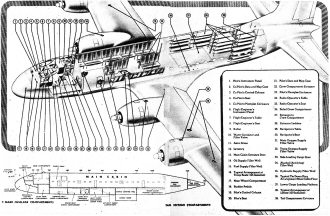

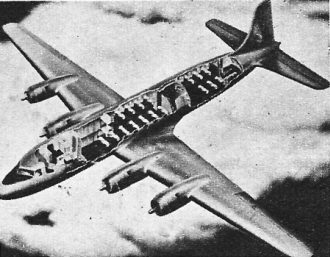

The Globemaster's interior. Planned as a troop transport, C-74,

holds 109 wounded patients on litters or 125 troops in seats. Crew facilities remain

similar in the civil version.

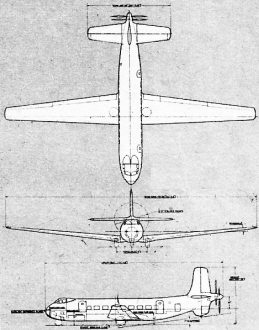

Model of original DC-8 with counter-rotating propellers.

Driven like an ocean liner with two counter-rotating props in

tandem at tail is the DC-8, forty-eight passenger transport planned by Douglas.

Shown above is three-view and model.

The DC-1, which cruised on its two Wrights at 170 miles an hour, was the first

twin-engine airplane capable. of flying and climbing with a full load on only one

engine. This airplane also had retractable landing gear, but it was not entirely

enclosed, It was this ship that the late Eddie Allen, during a test flight prior

to its public appearance landed with the gear retracted. Eddie's only comment on

debarking was, "Oh, for pity's sake!"

Before the DC-1 flew, however, much of the basic research from which all our

transports have developed, was completed. Aerodynamic calculations were particularly

concerned with performance and control at all attitudes of flight, both in normal

and single-engine operating conditions. Special designs of the controls, wing, and

fairing made possible continued, single-engine operation at high altitudes with

sufficient controllability to insure safety in meeting emergencies. Performance

studies to obtain the desired velocity, range and climb led to the choice of the

bi-motor type with controllable pitch propellers and high-lift wing flaps. The flaps

gave a gain in lift of thirty-five percent, and a drag increase of 300 percent.

Three complete wings were tested with various modifications of fuselage fillets,

tail surfaces, landing gears and tail wheels. Several sets of ailerons of normal

and special types, six arrangements of high-lift flap devices were among other special

arrangements tried.

Some of the early models tested in the wind tunnel showed instability and tests

revealed that it was necessary for satisfactory stability to have a hitherto untried

arrangement of center of gravity, wing sweepback and general configuration. The

actual airplane was built in accordance with this new plan and its stability in

flight proved to be exactly as predicted. Had not the wind tunnel tests been made,

it is possible the DC-1 would have proved unstable, since ordinary investigation

had indicated the original arrangement would be satisfactory.

As one result of these tests and changes, the total resistance of the complete

airplane was less than twice the resistance of the wing alone!

Wind tunnel tests indicated the best aerodynamic arrangement, but did not determine

the location and proportion of all structural details. To work it all out, we constructed

a mockup with wooden frames, covered with heavy paper to stimulate the metal sheet

covering. All frames were made in the exact sizes and locations of those in the

actual airplane. A complete floor was installed and various seating arrangements

tried to obtain maximum roominess and comfort. Final arrangement placed each passenger

chair opposite a window, gave' ample leg room, wide and unobstructed aisles, and

allowed a passenger over six feet tall to walk erect in the cabin. Many designs

of passenger chairs were tried before we finally chose an aluminum alloy structure,

so designed that the angle of inclination of the entire seat could be changed and

the back adjusted for sleeping. The seat was also reversible, permitting passengers

to face either forward or to the rear. This was the beginning of passenger comfort

in the air.

As for structural development, the studies of aerodynamics and general arrangement

showed the desirability of having the engine nacelles well ahead of the wing's leading

edge, a practice later found even more necessary on larger aircraft. It was also

found desirable to house the retractable landing gear within the nacelles. With

these points in mind, it was then necessary to develop maximum strength and rigidity

with minimum weight. Therefore, we designed a wing with the material so distributed

that there was little variation in the stresses of the various parts. At the same

time, the wing proved to have little or no torsional deflection, a minimum of vertical

deflection, and no excessively large unsupported flat metal surfaces.

In a metal wing, having a thin skin rigidly attached to a heavy spar, sudden

changes in cross section are apt to cause objectionable stress concentrations. Other

dangers exist as well. In seeking the answer to this problem we considered single,

two, three and multi-spar designs, as well as shell type and multi-cellular designs.

We finally decided upon the Northrop multi-cellular wing, a type we have employed

throughout all Douglas transports. This type of structure consists of a flat skin

reinforced by numerous longitudinals and ribs. Because the major loads are carried

in the outer surface of the wing as well as in the internal structure, inspection

of the exterior gives a ready indication of the structural condition.

In the fuselage, the structural problem was basically the same. This construction

consists of a smooth, stressed skin in contact with closely spaced over-strength

bulkheads and numerous longitudinal stringers. All parts are securely attached together,

and the skin has very small unsupported areas.

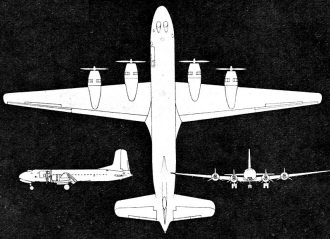

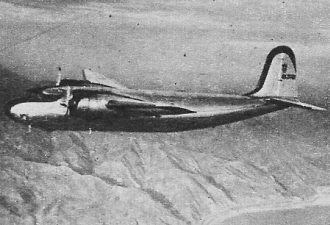

Three-view of the Globemaster.

Artist's drawing of the Globemaster. Other DCs led up to it.

Twelve passengers flew in the DC-1, and fourteen flew in the DC-2, which appeared

in 1934. The DC-2 was little more than a slight re-design of the DC-1. It really

was the production version of the experimental DC-1. The DC-2's fuselage was forty

inches longer to increase passenger capacity and assist in balance control.

Two years later the DC-3 appeared. This airplane, a real contribution to low-cost

travel, accommodated twenty-one persons in seven rows of seats, three passengers

abreast. As in the former models, wings were of full cantilever, multi-cellular

construction, as were the tail surfaces, but those were of aluminum alloy, except

for the fabric covering of elevator and rudder. It was in this model that the automatic

pilot appeared; and here, too, wing flaps of the split-trailing-edge type extending

from aileron to aileron came into service. Except for these changes of size and

construction, the DC-3 follows along the lines of its family. But the DC-3 paid

off much better, for, at 25,200 pounds this ship carried one and a half times as

much as the 18,560-pound DC-2. Wing loading had climbed, too, from twenty pounds

per square foot in the DC-2, to twenty-five pounds in the DC-3.

Next to come was the DC-4, more properly the DC-4E. We built only one of this

model in 1939 and it was subsequently sold to Japan. It was Douglas' first four-engine

plane, and had a gross weight of 65,000 pounds. It was designed for a pressure cabin.

The airlines thought this airplane, although it was ten percent faster than the

DC-3, was too large for their use. From this airplane, however, came the world famous

transport, the Army's C-54.

The new C-54, whose wing span of 117 feet, six inches, is only two-thirds that

of the DC-4E, was designed with the assistance of interested airline personnel and

finally approved by them. But the war came, and the Army took over its production.

The C-54 has tricycle landing gear, and is about two and one-half times the maximum

weight of the DC-3. The commercial version will give one-stop transcontinental service.

To date, some 1,000 of this type have been built, all going to the Army as C-54s.

It was one of these airplanes that was produced for President Roosevelt, and became

the "flying White House."

Passenger requirements and cargo requirements are somewhat different when an

airplane joins the Army. Special fuel tanks may be required for longer flights.

Some C-54s carried litters others accommodated forty-four passengers, yet others

flew more than twelve tons of freight.

In 1940 came yet another change and the DC-5 was born. This was a high wing,

twin-engine transport, of which only fifteen were built. All were sold to the Navy

and to the Dutch. It was a high-wing DC-3, and to that similarity the airlines objected.

At the same time, it presented differences which would have complicated their servicing

problems.

Not numerically but chronologically, next is the DC-7 Globemaster, or as it is

known by its first user, the Army, the C-74. The DC-7 illustrates how we must sometimes

design for two services simultaneously. As a military version, the C-74 carries

all cargo, no passengers. In designing and building the Globemaster, which was first

flown on September fifth of this year, we found the answers to a triple-headed question:

how much can we carry how far and how fast? Answers: thirty tons up to 850 miles,

7,500 miles with lighter payload, over 275 m.p.h. cruising (maximum).

The Globemaster is a big brother to the C-54 Skymaster, and is the first trans-ocean

airplane capable of flying non-stop from the United States to almost any point in

the world. As a military carrier, it can haul huge cargoes of jeeps, guns, fighter

airplanes, small tanks and trucks. On short notice, it can be converted into a troop

transport with a capacity of 125 fully equipped troops or a hospital ship with 115

litters. As the DC-7, it will carry a thirteen-man crew and 108 passengers.

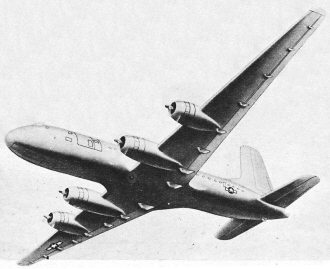

Only fifteen DC-5s were built. They were high-wing versions of

the DC-3.

Cutaway of the DC-6, scheduled to fly In 1946. Details unrevealed.

An artist's drawing of next year's DC-6. Its lines show great

promise.

Now, bearing in mind that the Globemaster's wings span thirty-two feet more than

those of the Super-fortress and that her fuselage is twenty-five feet, one and one-half

inches longer, how did we solve the problem of cargo carrying? First, we knew we

could devote the entire main cabin to this purpose. Next, we knew we must provide

proper cargo hoisting facilities. To meet these requirements, we designed a fuselage

which is circular in section, with a maximum outside diameter of thirteen feet,

two inches. The structure is of semi-monocoque construction, utilizing hat-section

stringers with zee and channel section transverse frames. Flush rivets are used

on all outside surfaces.

The floor of the main cabin contains approximately 875 square feet. The cabin

is seventy-five feet long and 11.7 feet wide, with maximum usable height of eight

and a half feet. Cargo may be loaded through a side loading door in the forward

area and through a bottom well immediately aft of the wing.

The Globemaster is the first airplane to carry its own cranes, hoists and cargo

elevator. Loading equipment consists of two traveling cranes, supported on overhead

rails in the fuselage roof, and a stationary hoist forward of the cargo loading

door on the left side of the cargo cabin. An elevator, supported at the corners

by cables, lifts cargo into the cabin rapidly. When not in use, the elevator is

secured in place by a releasable latch mechanism and becomes part of the cargo cabin

floor. The slide door hoist can lift 4,500 pounds, the cranes a total of 16,000

pounds when used together.

Remember, this is a cargo version. As such, it is important to handle cargo fast,

and in quantity. The Globemaster, therefore, with its self-loading equipment can

load, stow and haul ten R-3350 engines and cradles, or two T-9E1 tanks, two quarter-ton

trucks and two crew-and-ammunition carriers. It can carry other combinations as

well.

But let's look at the commercial version briefly. How do we plan to make this

airplane more comfortable for passengers? First, it should be remembered that larger

and later airplanes create more trouble from the noise standpoint. Power increases

faster than the art of soundproofing advances. The greatest problem is to keep the

noise down to that experienced in the DC-3. Cutting propeller tip noise by keeping

tip speeds well below the velocity of sound is one answer. Placing propellers sufficiently

far ahead of the passenger cabin so that wash-rooms or partitions will be between

props and passengers is another. Creation of "floating cabins" by separating walls

and bulkheads from main walls with rubber extrusions is yet another. Pressurizing

the cabin cuts the noise by about seven decibels.

The DC-6, which was delayed by war production and will not be flown until sometime

in 1946, is very like the DC-4. Innovations include an extra eighty inches in the

fuselage, R-2,800 Pratt and Whitneys instead of the R-2000s in the C-54 and also

a cruising speed of 300 miles an hour against 240. It will be completely pressurized,

with a cabin that can be either heated or cooled to an even temperature of seventy

degrees F. There is no change in wing span over the C-54, but a higher lift flap

will be employed. Three models will appear: the seventy-passenger day plane, the

fifty-two-passenger day plane and the twenty-six-passenger sleeper.

Passengers generally consider the DC-3 to be a comfortable airplane in which

to fly. But the successful airline operator knows he must compete with both air

and ground facilities to provide even greater comfort in order to hold and increase

his business. In the DC-6 all-sleeper deluxe, therefore, passengers will enjoy more

reliable heating and ventilation, better lighting, up-to-the-minute food service.

Due to its higher wing loading, 32.2 pounds, the DC-6 will ride more easily since

it will be less responsive to gusts.

These are generalities. They had to be worked out in minute details. E. Hamilton

Wright, chief of interior design for the company, sketched a dozen cabin interiors.

He built miniature cabins with miniature furniture. He painted them in various pleasing

combinations. As a result, should you ever fly in this airplane, you will enter

a door conveniently set just aft of the wing. From the foyer you may turn into either

the forward or aft cabin.

Once all passengers are aboard and the door is closed, the stewardess will commence

preparation of your next meal, working from two buffets, one on each side of the

door. From the rear buffet, she will take trays pre-loaded with fruits and load

them at the forward buffet with hot foods and liquids kept warm in thermos units.

You will relax in soft, luxurious cushion-rubber chairs. Later you may stroll

forward (if a gentleman) or rear (if a lady) to either lounge. In each will be found

a score of built-in accessories, as ash trays and electric connections in the men's

lounge. There will be a large sofa in the ladies' lounge. Indirect lighting will

illuminate each, while a lens shaving light will be provided for the necessary male

routine.

Long arm-rests, adjustable backs, removable and adjustable head- and foot-rests,

with full clearance for legs and luggage, characterize the seats. After darkness

falls, the stewardess will pull a few levers, and the seats will become berths.

Nor need you dawdle in the aisle aimlessly, for lowers will be made in thirty seconds,

uppers in ten!

The DC-6 and DC-7 serve the needs of long-range operations. The airlines have

other needs and to fit them we shall have the DC-8. This will be a low-wing, twin-engine

airplane which may well constitute as great an advance over the DC-3 as the Ford

tri-motor was over the Wright brothers' original biplane. The Sky bus will cruise

at 270 m.p.h. at 10,000 feet. It will perform beautifully on a single engine at

more than 12,000 feet and at the same time its landing speed is extremely low. Another

interesting innovation from an operations standpoint is that both take-off and landing

weights are the same, a gross of 39,500 pounds.

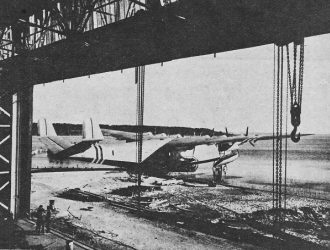

Latecoere De Marmier

The giant French flying boat, Latecoere 631, surnamed De Marmier after a French

war hero, is here shown shortly before its trial hop from Bordeaux to Buenos Aires.

Kept from Nazis by the French, she holds 100 passengers, ranges 6,000 miles.

We built for comfort in other airplanes, but in this one we tried to attain considerably

greater speed than we had in the DC-3. In fact, the DC-8, which will have motor

less wings and be driven by twin counter-rotating propellers, astern of the fuselage,

will be fifty percent faster than the DC-3, carry twice the number of passengers

and reduce direct costs per passenger-mile to half that of the plane which for twelve

years has been standard equipment on ninety-five per cent of the world's airlines

and supplied most of the Army's transport.

The DC-8, which will not appear for some months yet, represents a radical departure

from tradition. It will be driven exactly as an ocean liner is driven. It is in

the application to aircraft of this basically new principle of "center-line thrust"

that we believe the DC-8 represents outstanding improvements over conventional types

in speed, safety, climb and efficiency.

But it does not omit passenger comforts. A cabin innovation of great significance

is a movable partition that converts the plane at short notice from a combination

cargo-passenger to an all-passenger plane. By this means, the operator can be assured

of a 100 percent load on all flights where passengers and/or cargo are available.

The two engines, located in the fuselage below the forward compartment floor, are

connected with the propellers by drive shafts and a gear box similar to those of

an automobile. Allison engines were chosen because they were installed in military

experimental prototypes which have been test-flying for more than a year. This power-propeller

installation means a further reduction of noise within the cabin. Improved safety

is derived, too, since there is no offset thrust in case of engine failure, there

is an overall drag coefficient twenty percent less than in equivalent conventional

planes and better lift distribution resulting from the higher effective wing span.

Other details cannot be revealed to the public at this time.

There are some significant trends to be traced in the history of the DC family.

High strength materials have made an average of a fourth to a third increase in

strength. Later models use the new 75S aluminum alloy in all basic structures. All

models up to theDC-7 have three-spar wings. However, the DC-7 incorprates two-spar

wings, a change which increased fuel capacity by fifty percent, and thus increased

the range by the same proportion. All models through the DC-3 used brazier head

rivet construction. The DC-4, 6 and 7 have flush rivet construction, effecting lower

drag. Other improvements in later models result in lower drag and better cooling

in the nacelles. One of the biggest improvements is the complete sealing off of

the engine from the rest of the airplane structure, a change first appearing on

the original DC-4, The Skymaster.

It's a long road -fro m the DC-1 of twelve years ago to the Globemaster and the

Skybus, but it is one road. We have really been writing variations on a theme. For

though the granddaddy of them all weighed in at only 17,500 pounds (gross weight)

and the mightiest of her progeny, the Globemaster, weighs 155,000 pounds; though

the wing-load has increased three-and-a-half times, the first of the line was so

well engineered that very few fundamental changes had to be made. Each late model

grew out of the one that preceded it.

An airplane isn't really built; it is a process of evolution.

Posted July 16, 2022

|