|

Here is a really nicely

done Curtiss Pusher biplane model for control line. The original model had a 24" wingspan

and was powered by an .049 ignition engine, but you could easily adapt it to electric

power. In fact, doing so would eliminate the hassle of needing to hinge the tail boom

and empennage for accommodations easier engine starting. If you elect to build the Curtiss

Pusher, be prepared to do a lot of work because of the shaped wood sticks for the fuselage,

the undercambered airfoil (which could be modified to flat bottom

airfoil for simplicity in covering), and the flying wire rigging. It does make

a great looking subject, to be sure.

Curtiss Pusher

By Henry Struck

Back in the days when airplanes were "flying

machines" and jets were gas-light burners, Lincoln Beachey amazed America with his incomparable

precision flying and stunting. He was the first to power dive and zoom, whip stall and

spiral, as well as the first American to fly inverted and loop. To demonstrate the ease

and precision with which he could control his Curtiss "Tripod" pusher, Beachey flew for

miles up and down Chicago boulevards, skimming the tops of autos and trees. Back in the days when airplanes were "flying

machines" and jets were gas-light burners, Lincoln Beachey amazed America with his incomparable

precision flying and stunting. He was the first to power dive and zoom, whip stall and

spiral, as well as the first American to fly inverted and loop. To demonstrate the ease

and precision with which he could control his Curtiss "Tripod" pusher, Beachey flew for

miles up and down Chicago boulevards, skimming the tops of autos and trees.

Lincoln Beachey's machine was the product of the pioneering genius of Glenn Curtiss,

founder of the aircraft enterprises that bear his name today. Curtiss with his talent

for mechanics and zest for speed moved naturally from racing bicycles to motorcycles,

to flying, dominating each field in turn.

Overshadowed perhaps by the more spectacular performances of his flying machines was

Curtiss's development of light weight, reliable power plants - notably the liquid-cooled

Vee arrangement. The engine in Beachey's pusher was the predecessor of the almost universal

OX-5 of the '20's, and today has reached its peak of refinement in the Allison and Rolls

Royce types. This contribution of practical power, enabling others to materialize their

theories of design, hastened the development of the airplane immeasurably.

|

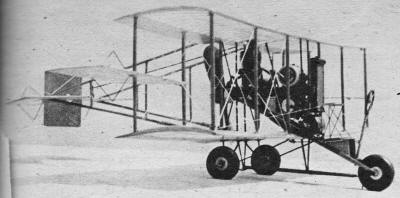

The problem of starting the pusher engine without interference from the boom members

has been solved by hinging the aft section.

|

After Curtiss had taught himself to fly, becoming the holder of international Air

Pilot Certificate No.1, he realized the necessity for training others, and established

the Curtiss Flying Schools. Most of the early pilots, including Beachey, and many World

War I flyers received their early training under this system.

With its premier position in aviation history the Curtiss "Tripod" Pusher is a most

interesting and challenging model project. The numerous flying wires, struts and open

air controls afford the opportunity for much detail.

To support the weight of the Bantam engine successfully the landing gear and center

section braces are an integral structure of piano wire, on which the wings merely rest.

A difficulty: common to all pusher models - flipping the prop for starting - required

a radical solution. The entire tail was hinged at the upper surface and clipped into

sockets at the lower wing, permitting the assembly to be swung up and out of the way

without disconnecting any controls.

In

the absence of a regular fuselage, the wings must be built first to provide a structure

from which the remaining elements of the model may be located. Cut out 52 ribs of 1/16"

sheet, and 6 of 3/8" sheet. This can be greatly speeded up by snipping a wing rib section

from thin sheet metal and cutting around the template with a razor blade. Shape the trailing

edges to a wedge section, 1/32" thick at the rear edge. Pin the leading edge, shaped

of 3/16" x 3/8" hard balsa, to the plan at an angle to match the nose of the ribs. Cement

the tip and center ribs to the leading edge and pin the trailing edge against them. Fit

shims under the junction of the ribs and trailing edges to maintain the contour of the

wing section. Insert the remaining ribs, and fit the spars of 1/16" x 3/16" hard balsa.

Remove the wing from the plan when dry and re-cement all joints. Sandpaper the framework

carefully to remove any bumps that may spoil the finish. Cover the wings with light weight

Silkspan, sticking the paper to the bottom of each rib to preserve the camber of the

section.

Shape the wing struts A, of 1/8" x 3/16" hard balsa to a streamline section at the

center and to 1/8" diam. at the ends. Drill 1/8" holes through the wings and cement the

struts in place, beginning at the tips and working toward the center.

Form the upper portion of the rear motor support B, and the front support D, of 1/16"

piano wire. Cut two plates C, of .020 brass strip. Drill a number of large holes in them

to permit the cement to anchor them securely to the wing surface. Slide the motor supports

through the plates and complete the bends. Push the wire supports through the slots provided

at the center of the wings and cement into the upper wing.

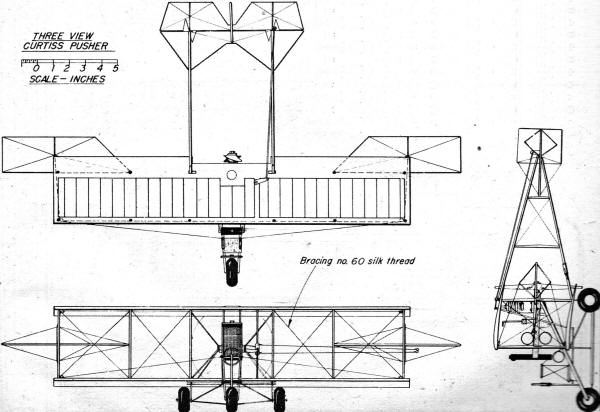

Curtiss Pusher 3-View

Attach the motor mounts E, of ,1/4" x 3/8" maple to the supports with clips F, of

.020 brass strip. Form the motor braces G, of .049 piano wire and work them carefully

into position through the bottom wing. Enlarge the holes through the wing if necessary

to simplify installation. Clamp the braces to the outside of the motor mounts with clips

F. Bend the front wheel support H, of 1/16" piano wire. Clamp the rear end to the inside

of the motor mounts with a brass clip, and bind to the front motor support with fine

wire. Form a pair of rear axle trusses I, of .049 piano wire. Clip the inner ends into

the rear plate C, and bind the outer ends to the motor braces G, with fine wire. Link

the trusses I, to the front wheel support H, with it fork J, of .049 wire, Check the

alignment of the wing assembly carefully - bind all overlapping joints with fine wire,

and solder. Solder the clips F, to the struts, and solder the nuts of the 2-56 machine

screws to the clips to simplify assembly. Solder the struts to the plates C wherever

they pass through. Be sure all parts are clean and bright. Use acid core solder, a well

tinned iron, and the job can be done quickly without danger of charring the wings. Fair

the struts Hand J with strips of 1/8' x 3/16" hard balsa recessed to fit the wire.

Make two bearing plates O, of .020 brass to support the control shaft. Drill 1/8"

holes through the 3/8" thick ribs. Assemble the horn N, of .030 brass and a 1/16" I.D.

eyelet, on the shaft in the mounting bracket M. Solder the horn assembly to the shaft

and slip the unit into the wings. Bolt the bracket to the motor bearers and cement the

bearing plates O in position. Slip the upper horn P, and the lower horn Q on. the shaft

and solder quickly in place to prevent charring the wood. With the horn N parallel to

the motor bearers, the upper horn P should be pointed toward the boom hinge point, at

an angle of about 60°. The lower horn Q points toward the center, parallel to the

wing span.

Fit the engine in place and mark the bolt positions. Remove the bearers and drill.

Attach the motor and work the unit back in place.

Assemble the tail booms directly on the plans of 1/8" dowels, joined by 3/32" x 1/8"

hard balsa streamlined struts. Use several coats of cement at the joints. Lash the hinges

L, to the booms with thread and coat with cement. Slip the booms onto the spur of brace

G protruding above the upper wing. Fit bearing K in place and solder to the wires where

they intersect, using a minimum of solder to prevent seizing up the hinge.

Cut the stabilizer of 3/32" soft sheet balsa, sandpaper carefully and cover with Silkspan.

Set the stabilizer in place and align it with the wings while locating the lower

ends of the booms. Reinforce the boom with a wedge of 1/8" balsa. Cut the lower booms

apart and cement sockets of 1/8" I.D. aluminum tube in place on the stubs. Push the booms

in place and file the notches in the dowel stock. Raise the tail and bevel off the upper

part of the dowel in front of the notch, to permit it to snap into place. Drop the .016

piano wire clip in the notch and lash to the boom with thread and coat with. cement.

Hang the elevator on the stabilizer and solder the horn R, to the left hinge. Form

a 1/8" I.D. eye in a 12" length of .049 piano wire and hook it into horn P. Set the elevator

in neutral, and with horn N parallel to the motor bearers, bend the end of the push rod

into the elevator horn. Solder a small washer to the end of the' wire to retain it in

the horn.

Cut the ailerons of 3/32" soft sheet balsa. On the original model they were hung on

the rear struts with hinges S, of .020 brass. Threads passed over 1/4" diam. eyelets,

cemented in the corners of the front struts, connected the ailerons to the shoulder yoke

at the seat. Diamond shaped horns of .020 wire were cemented to the surfaces. The upper

line was rigged from the left aileron to the right, over the upper fairleads. Each lower

line was rigged to the corresponding side of the shoulder yoke, over the lower fairleads.

For flight the yoke was locked in place. If desired the ailerons may be merely cemented

to the struts, or omitted entirely for flying.

Mount the control column of 3/32" diam. dowel between the seat supports with a short

shaft of .020 wire. Link the column to the U-control system with a push rod of .049 wire.

Cement the control-line guide of .049 wire to the left outboard struts, just below the

ailerons. Attach a pair of .016 lines to horn N, and pass them through the guides.

Install the ignition system using medium size batteries and a midget coil. Solder

all connections and lash the batteries and coil in place with a couple of turns of rubber.

Lead the negative side of the battery to the ground and provide a booster attachment

on the positive side of the coil.

A heavy, wide bladed propeller is necessary to absorb the torque in the small diameter

required. Carve a left hand prop of maple, using a spokeshave and cabinet rasp for speedy

roughing down.

Build up a dummy radiator of 3/8'" soft balsa and cover the front with fine wire screen.

When cemented between the motor bearers the batteries are considerably camouflaged by

it.

Apply several coats of shellac to all bare wood parts. Spray the wings with water

to shrink the tissue and apply two coats of dope, and one of thinned shellac when dry.

Finish all wire struts and horns with flat black paint.

When flying, clip booster leads to the ground and coil. Be sure they are not crossed.

Release the tail booms from the sockets and lay the tail over the top-wing. The prop

can then be easily flipped over in the conventional manner. A length of rubber tubing

slipped over the intake pipe, projecting between the batteries and radiator, may be pinched

shut to simplify choking and eliminate priming. No trouble was encountered in operating

the engine with the propeller specified. Closing the booms while the engine is running

proved even simpler than expected, due to the smooth functioning of the clips. For the

most stable flights the C.G. should be well forward. Add weight to the front wheel support

H, under the seat, if required.

Due to the tricycle landing gear the model may be run easily along the ground, lifted

off when desired and brought down without danger of nosing over while feeling out the

controls.

Wherever exhibited the Curtiss Pusher will always provoke discussion of the pioneer

days, of the men like Lincoln Beachey who flew with such skill and daring, and of others

like Glenn Curtiss who created the machines through vision and infinite patience.

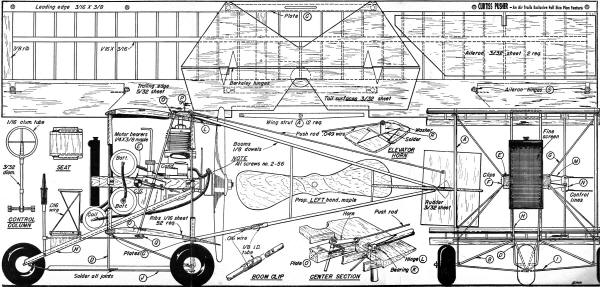

Curtiss Pusher Plans

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted November 1, 2014

|