|

"Red birds are much like

our own." That was written of a Ruskie publication reporting on a model rocketry

contest in the USSR. Of course, this story is from a 1963 edition of American Modeler.

Back then Communists (Russians, Chinese, North Koreans, etc.) were colloquially

referred to as "Reds". The main topic of the article, though , is the growing popularity

of rocket boost gliders. A few attempts have been made over the years to try rocket

boost R/C models, but without much success. Also covered is the obstacle being faced

by groups trying to recruit new rocketeers because of the "killer" reputation homemade

model rocket engines had acquired from careless and/or ignorant handling of the

explosive components. Vernon Estes single-handedly changed the fate of the model

rocket hobby by introducing preloaded, solid propellant motors.

Rocket Trails

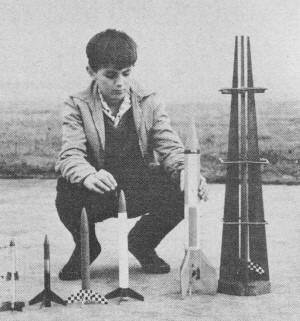

Young contestant at Krakow with typical Polish

rockets and launching cradle.

by Harry (Old Rocketeer) Stine

B/G's Challenge Modelers; "Basement Bomber" Scare

The entire field of boost-gliders (B/G) is rapidly growing into a distant and

separate part of model rocketry. More and more modelers are devoting all their time

to these little winged beasties. I talk a good deal about B/G in these columns for

several reasons: (1) B/G is a wide-open subject that interests both model aviators

and model rocketeers; (2) it is an area in which a great deal of aeromodeling research

remains to be done; and (3) it involves more than just up-and-down. It is also a

form of model rocketry in which both the advanced expert and the raw be-ginner can

and have made contributions. The number of different B/G designs currently flying

are marvelously varied, and the state of the art is progressing at a high rate.

National NAR record for B/G Duration is 2 minutes 28 seconds - held by Mrs. Gleda

M. Estes, a housewife with 3 children. Just the other day, I witnessed an unofficial

flight where the clock was stopped at 1 minute 45 seconds because the B/G glided

out of sight ... and it had been powered with a Type 1/2A.8-2 engine with no attempt

to open it up by using a Type 8.8-4.

Close-up shows winning model at right which attained altitude of 1,817 feet.

Body is rolled laminated paper tube, 1.3 mm thick with tail end reinforced

with 1.5 mm plywood to which four plywood fins are attached. Rocket motor body

was also of rolled and glued paper with a metal diffuser. Overall length, 13 inches;

body diameter 1.12 inches; total fin area 48 sq. in. Meets are run by

Polish aeroclub; half the entrants are under 12.

One of my most successful B/G designs, although far from being a record-breaker,

is the Eaglerock, a reliable bird first airborne in 1961 and one whose design has

been refined from countless flights. Don't give me any exhaust gas about it looking

like an eagle and flying like a rock, because that phrase is reverently reserved

for the old Alexander Eaglerock bi-planes that were made in the 1930's in Colorado

Springs.

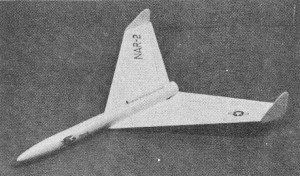

My objective with the Eagletock B/G was to design a rocket-powered high-performance

flying-wing glider with every good aerodynamic characteristic that could be stuffed

into it. In its present form, it is probably the cleanest B/G flying. It has a minimum

number of external parts to keep parasite drag down, it utilizes generous fillets

to reduce interference drag, it has a wing with high and effective aspect ratio.

Constant-percentage elevons are used.

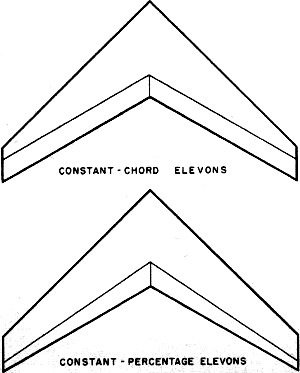

By way of quick explanation, constant-percentage control surfaces have a chord

that is a constant percentage of the wing chord. If the wing tapers, so do constant-percentage

control, surfaces. On the other hand, constant-chord control surfaces have the same

front-to-back dimension throughout their span, regardless of wing chord. There is

some advantage to constant-chord elevons on a swept-tapered wing, because they make

the wing tips fly at a negative apparent angle of attack, thereby discouraging the

tip-stall that is a characteristic of swept wings. On the other hand, constant-percentage

elevons produce less rolling moment and lower induced drag.

Since the stall characteristics of a flying wing such as a B/G are pretty miserable

(the only way you can eliminate it is to use a canard configuration), I chose the

constant-percentage elevons because I wanted lower drag, a cleaner glide with a

low sink rate, and proper trim without worrying about stall anyway.

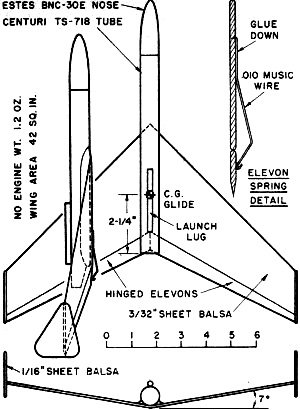

Body of Eaglerock is Centuri TS-718 paper tube, i.d. 0.710 inches, length 8 inches.

Nose cone is Estes BNC-30E slightly trimmed to fit the smaller tube. Model is rigged

to use the "casing-jerk" system. For flight, empty engine casing with old nozzle

busted out is taped to front of new flight engine, thereby putting more weight up

forward during boost. On ejection, both engine casings are expelled from the model.

To use casing-jerk system in Eaglerock, glue engine bulkhead into tube 5.5 inches

forward of rear end.

Elevon settings are determined by the amount of clearance cut away from rear

end of body tube at its lower point. To start with, cut only a small clearance for

elevons, if you require more up-elevon later, you can take off more tube. Elevons

are stopped by tube cutaway.

Meanwhile in the USSR model rocketry gains recognition as is

evidenced by these pages from a Russian publication. Red birds look much like our

own: non-metal; standard fuel.

"Eaglerock" B/G fuselage tube cut at

bottom rear acts as upward stop for elevons.

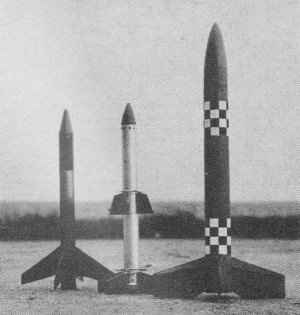

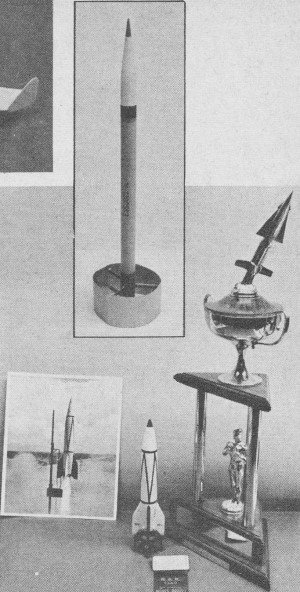

From upper left: Ring-tailed "Essobee-Hi" by GHS. Revell plastic V-2 modified

for flight won trophy shown for Ole Rocketeer.

Collection of B/G's shows variety of designs, kits available.

Wings are 3/32" medium-hard sheet balsa cut with grain parallel to leading edge.

Round leading edges with sandpaper; butt-glue wings together at root with 7°

dihedral in each wing. Cut elevons from 3/32" sheet with grain running spanwise.

Round leading edges of elevons and taper trailing edges. Attach elevons to wings

with tissue or Silkspan hinges as is done for U-control elevators.

Attach wings and elevons to body tube with double-glued joints. When dry, add

wing root fillets. I find that good fillet material is AMT Body Putty for plastic

cars; it's easy to apply and sands to a smooth finish. Wing root fillets reduce

wing-body interference drag by at least 50%.

Cut tip rudders from 1/16" sheet with grain running parallel to leading edge.

Sand to symmetrical airfoil. Glue to wing tips as shown - be sure that elevons move

freely. Tip rudders greatly reduce the induced drag caused by vortices generated

at wing tips and serve to increase the apparent aspect ratio of wing.

Glue scrap balsa eleven depressors to elevons roots so that an installed engine

casing holds the elevons at zero (and I do mean zero) incidence. If elevons are

not at zero incidence, model will loop under power after leaving launch rod.

To provide up-eleven action, most B/G designs use an elastic cord under tension.

This creates drag because of circular cross-section of elastic. Eaglerock uses gen-u-wine

Old Rocketeer Low Drag Elevon Springs made from music wire and glued under root

of each elevon as shown.

Add small fillet of glue at wing-rudder joints to reduce interference drag there.

Glue launching lug to top of tube. I tried to cut down drag by eliminating lug,

but could not figure how. Location of lug reduces slip-flow around rear of body,

probably adds to glide characteristics. (Wind tunnel checks may confirm this wild

hypothesis.)

Model should balance 2.25 inches forward of rear end of body tube without engine

installed (in glide condition, in other words). Don't worry if it is farther forward

- you will just require a little more up elevon in this event. But if it is farther

aft than this, you may be in trouble during powered flight, so add a little weight

to the nose.

Completed model weighs 1.2 ounces, has 42 square inches of wing area. This is

better wing loading than any present B/G kit model, but is not as good as some of

original design high-soaring contest-winning B/G's. Further refinements may cut

gliding weight, but 1/16" sheet balsa wings have not been successful to date. Thin

wings of this span have a tendency to leave the party during powered flight.

Eaglerock is designed to fly from a 36" rod launcher. Ascent is clean and straight.

Glide is fast but flat when properly trimmed. Some trim flights using half-A size

engines will. be necessary.

Great controversy, still unresolved, rages over type of finish that is best for

B/G. I maintain that smooth, slick finish is better because it forestalls boundary

layer turbulence and consequent increase in friction drag. Devotees of rough, unpainted

balsa B/G's claim paint's extra weight is N.G.

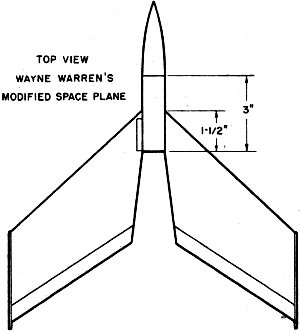

Wayne Warren of Pontiac, Mich. sent in a crazy modification of the Estes Space

Plane shown. Body tube is cut to 3" length. Nose cone is hollowed out and glued

to body tube. Elevons are glued flat to wings, and wings are cut away aft as shown

to clear jet of engine, Space Plane spin tabs on rudders are not used. Wings are

glued to body tube in mid-wing configuration like Aero-Bat. My feeling is that this

short wing joint may have to be strengthened with Silkspan or such to keep wings

on the bird during powered flight. Short launch lug is glued to side of body. Engine.

ejection simply pulls weight out of nose. Bird can be trimmed only by adding or

removing weight from nose. Wayne reports 1 minute 41 seconds - respectable time

indeed. He sez modified Space Plane is faster-climbing than any other observed.

Trials and Tribulations Dept. Following communication comes

from Fred Hypes of Lexington, Ky. Much of it may be an old story to many of you.

It's certain to interest new comers:

"Trying to get the new concept of model rocketry started in a city just starting

to grow itself is difficult at first. Then problems narrowed down to major catastrophes.

I figured when I started in 1961 that I would have a very hard time proving the

safety of model rocketry.

"It never helps when model rocketry has been labelled 'Killer.' I was shocked

when I asked a friend if he was interested. His reply was: 'Next to raising poisonous

Australian bushwacker snakes, you have the most dangerous hobby in the world.' Naturally,

I thought he was getting amateur and model rockets mixed up. But he told me that

he had read articles about model rockets killing people. I immediately told him

he was mistaken.

"A few weeks later, I found out what he was talking about. It wasn't model rockets,

but amateur rockets which had been called model rockets. It gets kind of tough when

your teachers, after you mention something about your model rocket club, start giving

lectures on the danger of rockets in front of the class.

"This probably started when two boys from our school were injured with home-made

rockets. A best friend of my classmate blew the top of three fingers off while stuffing

matchheads into a CO2 cartridge. Then the classmate fools with a homemade propellant

in a metal tube and gets enough shrapnel in his leg to build a bridge.

"So everyone is in an upheaval over rocketry. Still, our club is trying hard

to ward off attacks on model rocketry by giving demonstrations. Last year our small

group flew over 200 rockets in less than 30 flight days. We've talked before scout

troops, science classes, and clubs and groups of every sort. We have also entered

several science fairs and exhibits. I don't think that much more can be done."

The "model rocket" incident to which Fred refers is an example of what model

rocketry isn't. On February 20, 1963, Billy Wayne Barton (22) and Phillip Barton

(14) of Phoenix, Arizona took a piece of 1" steel pipe, put some sheet metal fins

on it, and threaded a steel nose cone to the front. Into the tube they poured over

a pound of black powder that their father had for loading shotgun shells. They stood

the "bomb" on its fins on a piece of sheet metal in their backyard and tried to

light it with a match. When it wouldn't light, they poured a can of lighter fluid

into the powder. Their second try at lighting it with a match sure succeeded - unfortunately.

The explosion rocked the neighborhood. Billy Wayne was dead on arrival at Memorial

Hospital in Phoenix. Phillip underwent surgery

for numerous shrapnel wounds in his legs and arms. Their father, Frank W. Barton,

was painting a door 40 feet away when the explosion blew him off a ladder and peppered

his left shoulder and right knee with shrapnel, The Phoenix papers called it a "model

rocket." It was not. This was called to the attention of one editor during a personal

visit by spokesmen from the NAR's Valley of the Sun Section in Phoenix but to no

avail. The story went out on the nationwide wire services as a "model rocket accident."

You model rocketeers are engaged in a safe hobby which has produced over 1,500,000

flights without any accidents.

Unfortunately any accident where someone gets hurt with a basement bomb also

damages our hobby in a way entirely undeserved. Model rocketry has protected the

lives and limbs of thousands of people (mostly youngsters) who would otherwise have

tried to make their own rocket engines. If people wonder why I am so vehement about

Basement Bombers, the Phoenix incident is an example.

This brings up a query I received from a Potomac, Maryland, follower of this

column who apparently doesn't believe what he reads. His comments:

"I and another boy are building a rocket, and need some information. You stated

that a rocket amateur could purchase most anything he needed. Also, you stated that

most amateurs did not have the know how to make many parts of a rocket. Both of

us being Seniors in High School, I feel we have a good deal of know how, but we

are lacking in a very common category - monetary. We feel that some of the essential

parts, we could buy cheaper than we could make them.

"We would like to know where we can purchase the following:

"(1) A liquid fuel, mono-propellant nozzle using 87% H202,

and exerting a thrust of 1.5 x 103 lbs.

"(2) Parachutes to lower, as gently as possible, a 100 lb. 1st stage, a 75 lb.

2nd stage, and a 25 lb. payload (all liberal estimates.)

"(3) A sponsor. Do you know anyone who would be interested in sponsoring a project

such as this?"

We can only hope somebody collars these two and gives them the Word before we have

another Phoenix incident on our hands. I ask you, how much "know how" can they have

about rockets?

Contrast their letter with this one from James R. Newton of Osseo, Minn.:

"I have been a fan of yours long before I joined the NAR. The first time I heard

of the NAR was in an article you wrote in 1961 for American Modeler magazine on

new concepts of model rocket design. More AM articles drove me farther away from

amateur rocketry and closer to model rocketry. In fact, my first kit was the Astron

Mark, one of your own designs. NAR-approved model rocket engines have superior performance.

Your articles in AM are very informative. Keep up the good work."

I give the matchstick/gunpower crowd this thought for the month: If you load

your own, the smoke in the basement may be Y-O-U!

Ring Tails? From Barry Orton, Bayonne, N.J., the following:

"Please tell me more about ring-tails. Your article in the November 1958 issue

of AM did not give me enough info."

A ring-tailed model has a single cylindrical fin around the tail section instead

of ordinary flat fins. It is often held in position by small balsa struts, or even

by stub fins. The equivalent flat-plate fin area of a ring-tail is 1.4 times the

area of a side-view projection of the ring. Ring tails have no stability in roll.

For optimum performance, the ring chord should be about 1.5 calibers (rocket diameters).

The greater the diameter of the ring, the greater the stability but the less the

thrust augmentation effect. Ring tails are very stable models, but are slow because

of the drag of the ring supporting struts. They do not fly well in a wind, as the

ring tail tends to stall out completely because the air flow through the ring gets

choked off.

I once thought that this flow-choking stall of a ring-tail was a unique discovery

of model rocketry. But Adm. Levering Smith, formerly of the Polaris program, pointed

out to me that the Navy had run into the same problem many years ago with ring-tail

"hedge-hog" rockets for anti-sub work. Ring-tails are interesting, but they don't

like high winds. I have built and flown some ring-tails, and have watched many others

fly. They are interesting, but flat fins seem to do the job just as well and are

easier to build.

Federal Control. On March 14, 1963, the FAA put into effect

Part 48 of the Civil Air Regulations, "Operation of Unmanned Rockets." The new regulation

closely controls the flight of amateur rockets. Clearances must be requested well

in advance for amateur rockets. However, Paragraph 48.21 of this new regulation

specifically exempts model rockets from FAA control provided they weigh less than

16 ounces, have less than 4 ounces of propellant in them at takeoff, are made of

non-metallic parts, and are operated so that they do not create a hazard to aircraft.

It took Bob Hurley of the FAA nearly 4 years to get this regulation into effect.

I understand that the amateur rocketeers gave him a good deal of trouble on it.

On the other hand, the NAR and model rocketeers can be honestly credited with helping

the FAA in many ways to establish a reasonable, workable regulation.

Gentlemen, the new FAA reg doesn't mean that you can set up a launcher on the

end of runway 27 without permission. But it does mean that you can fly the kind

of model rockets we talk about without checking FAA.

HQ Change. The National Association of Rocketry has a new address:

National Association of Rocketry, Stamford Museum & Nature Center, Stamford,

Conn.

Mass. Nats. The NAR has announced that the Fifth National Model

Rocket Championships (NARAM-5) will be held August 22-25, 1963 at L.G. Hanscom Field,

Bedford, Mass., not far from Boston. Contest Director is Marshall P. Wilder. Fifteen

events are scheduled, including classes for the new model rocket engines we talked

about last issue. However, entry will be limited to 50 contestants chosen by the

NAR Contest Board from the best model rocketeers in the nation. Sponsor of the meet

will be the USAF Systems Command. Of course, your AM reporter will be there, alert

and omnipresent, cameras slung about the neck, sunburned tonsils pointed skyward.

Not So Easy. "Plastic Scale" is a unique competition event in

the NAR Sporting Code. The rules require that you modify a non-flying plastic scale

model of a rocket or missile so that it will fly. You must also have data to show

that it is indeed scale. It's an event with a lot of challenge to it, for many reasons.

Not only does it take skill on the part of the modeler to make the necessary modifications

to the beast, it also requires the skill and patience of a bloodhound to find a

plastic kit of a rocket that can be modified.

In hobby stores, you can get plastic models of every automobile ever heard of

and millions of different aircraft. But very few rockets or guided missiles. In

1957, 1958, and 1959, rockets and guided missiles were very IN with plastic manufacturers.

You could find 'em by the hundreds. I have built every plastic rocket and missile

ever produced, and we used to be able to get some dandies. Today, they are as scarce

as homes for kittens. Hawk's Jupiter-C is no longer available, but would make a

beautiful flying job. Same holds true for the big Kay-Sun plastic missiles that

were too big at the time for the power of any of our engines but which would be

just right today for flight mod.

Revell is the only one today that makes anything capable of flight mod. Their

Corporal, German V-2, Lockheed X-17, and North American X-15 are all capable of

flight mod, and I have seen these little plastic birds turn in very nice flights.

The Revell Terrier and Nike-Hercules kits don't modify because of size or stability

problems. And these kits are often very hard to obtain. Every time I find one hidden

on the shelf of a hobby story, I buy it and cache it away for future use.

Accomplishing a good flight mod often means that you have to throw out over 50%

of the parts in the kit. It requires a good deal of head scratching to figure out

a way to mount engines, get the recovery system in, and achieve the proper balance

for stability in flight.

You must do a darned good job putting the model together because it isn't going

to merely sit on a desk - it's going to fly at speeds of 150-mph or more. Problems

arise involving the compatibility of glues, since many internal parts of a flying

plastic job are made from balsa. Finishing the model is often a challenge due to

the different types of enamels involved. The end result is more than worth it, because

you can sit it on the mantle with all of the non-flying plastic erectors that go

with it and proudly announce to people that it is a little bit different from all

the other plastic models around. It flies, too.

One of these days, Utopia will arrive. A plastic manufacturer will come up with

such Space Age plastic models as Ranger, Mercury, Gemini, Apollo, Saturn C-5, X-20

Dyne-Soar, and others of this ilk. You will be able to buy the kit in two forms:

non-flying and flying. They will be designed in such a way that they are large enough

to be powered by existing model rocket engines.

In the meantime, hobby stores with their racks of plastic models give you the

impression that we are still in the age of Barney Oldfield and Eddie Rickenbacker.

Doesn't the hobby business believe that we are in the Space Age?

Posted April 6, 2022

(updated from original post on 7/28/2012)

|