|

When I first saw this "U-Control

Model Plane" article in a 1952 issue of Popular Mechanics magazine, I expected

it to have been written by one of the

Stanzel brothers. Long after their entry into the model airplane manufacturing

world, Joe and Victor created their line of

battery-powered, electric motor-driven control line models in 1958. It eventually

included a helicopter, a monoplane, and a flying saucer, amongst other craft. The

Stanzels, BTW, invented the Monoline control line system which was adopted by U-control

(aka control line) speed modelers because it created much less aerodynamic drag,

facilitating higher airspeeds. Maybe this article was a motivation for the Stanzels

since it predates their product line. I personally had both the

ElectroMic Tethered "Flash" airplane and the

ElectroMic

Tethered "Copter" helicopter back in the late 1960s. Anyhoo, this would make

an interesting project for your kids.

U-Control Model Plane

By Kai M. Klemm By Kai M. Klemm

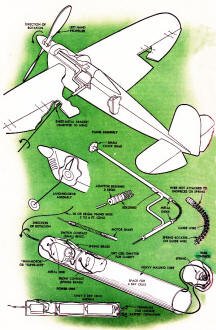

Powered by a novel electrically driven remote-control unit, this tiny plane will

fly level, zoom and loop on a circular course in a small living room. The control

unit, which also supplies power, is housed in a mailing tube about the size of an

ordinary flashlight, except that it is slightly longer to accommodate four flashlight

dry cells and a tiny electric motor. The motor drives the propeller through a "flexible

shaft" of fine piano wire, the length of the wire depending on the radius of the

flight space available. Because of the constant speed of the left-hand prop and

the connection of the flexible shaft to the fuselage at its center of gravity, the

plane maintains level flight without any tendency to nose down due to torque.

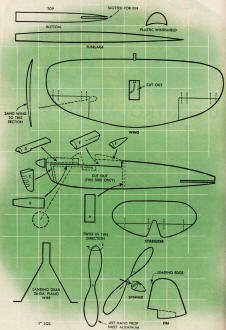

All parts of the plane are made of balsa-wood, except, of course, the angle drive

and the landing gear. Sheet balsa, 1/16 in. thick, is used for all parts except

D, E and F in the details on the following page. The sides of the fuselage are made

first, then the bulkhead, A, is glued in place. Next, both the sides are glued together

at the tail and cowl block, C, is glued in place. The landing-gear frame is bent

to fit inside the fuselage and must be cemented in place before the bottom is put

on. The inclination of the frame is shown by dotted lines on the details. After

gluing on the bottom, the fuselage is sanded to contour and sides are slotted for

the stabilizer. Now make the wing, stabilizer and fin, but do not attach the wing

until the angle drive is in place.

The details on the opposite page show the

assembly of the angle drive and how it is placed in the plane. The drive housing

consists of two pieces of 1/16-in. o.d. brass tubing held at right angles by a brace

of brass wire to which the housings, or sleeves, are soldered. The piano-wire shaft

from the motor is passed through the short sleeve so that the end projects. A thin

metal disk about 3/16 in. in dia. is soldered to the end of the wire. Then a length

of the piano wire is inserted in the long sleeve, cut to required length, and a

3/16-in. metal disk is soldered to the end. The flexible connector between the two

shafts is made as in the right-hand center detail on the opposite page. The drive

is made through a fine coil spring of the type and weight found in camera-shutter

releases. The ends of the spring are soldered to short bushings cut from 1/16-in.

o.d. brass tubing and the outer ends of the bushings are soldered to the metal disks

at the ends of the flexible shafting. Before soldering the bushings to the metal

disks, pass a length of spring-brass wire through the bushings and the coil spring

and bend to a uniform curve, cutting to length as required. When the assembly is

made and all parts have been soldered in place, the spring and bushings turn on

the curved-wire guide. In this manner power from the flexible shaft is transmitted

at right angles without buckling the spring. Care must be taken in assembling to

assure that the curved wire is free at the ends and that the metal disks do not

bind against the ends of the short and long sleeves. Adjust the unit by bending

the wire brace until it turns freely. The details on the opposite page show the

assembly of the angle drive and how it is placed in the plane. The drive housing

consists of two pieces of 1/16-in. o.d. brass tubing held at right angles by a brace

of brass wire to which the housings, or sleeves, are soldered. The piano-wire shaft

from the motor is passed through the short sleeve so that the end projects. A thin

metal disk about 3/16 in. in dia. is soldered to the end of the wire. Then a length

of the piano wire is inserted in the long sleeve, cut to required length, and a

3/16-in. metal disk is soldered to the end. The flexible connector between the two

shafts is made as in the right-hand center detail on the opposite page. The drive

is made through a fine coil spring of the type and weight found in camera-shutter

releases. The ends of the spring are soldered to short bushings cut from 1/16-in.

o.d. brass tubing and the outer ends of the bushings are soldered to the metal disks

at the ends of the flexible shafting. Before soldering the bushings to the metal

disks, pass a length of spring-brass wire through the bushings and the coil spring

and bend to a uniform curve, cutting to length as required. When the assembly is

made and all parts have been soldered in place, the spring and bushings turn on

the curved-wire guide. In this manner power from the flexible shaft is transmitted

at right angles without buckling the spring. Care must be taken in assembling to

assure that the curved wire is free at the ends and that the metal disks do not

bind against the ends of the short and long sleeves. Adjust the unit by bending

the wire brace until it turns freely.

The angle-drive unit is assembled in the fuselage as in the upper detail on the

opposite page. First glue part B in place, then cement the long sleeve, or propeller

shaft bearing, to it. Note that a part of the brace and the short sleeve project

from the opening in the side of the fuselage. Next, sand the wing to the airfoil

indicated in the detail and cut out and hinge the ailerons with lengths of fine

copper wire. Cement the wing in place on the fuselage with a 3-deg. angle of incidence.

Then add the rear cowling, E, the windshield and headrest fairing. As the final

step in this assembly, bend a bracket bearing from sheet brass and drill a hole

for the piano-wire shaft near the end of one arm. Then slip the bracket over the

wire and cement it to the underside of the wing as shown.

The power unit, shown in the lower details

on page 188 consists of a mailing tube divided into two compartments, the smaller

housing the motor, with its shaft projecting through an oversize hole in the cardboard

disk which is cemented or taped to the end of the tube. A coil spring about 1 in.

long and of the same general characteristics as that used in the angle drive is

used to form a flexible connection, or universal joint, between the motor shaft

and the piano-wire shaft. In order to make the connection it will be necessary to

solder a suitable bushing to the end of the piano-wire shaft as shown in the detail.

Then the spring is slipped over the bushing and soldered. It is not soldered to

the motor shaft, as a tight fit is sufficient to transmit the full power of the

motor. The power unit, shown in the lower details

on page 188 consists of a mailing tube divided into two compartments, the smaller

housing the motor, with its shaft projecting through an oversize hole in the cardboard

disk which is cemented or taped to the end of the tube. A coil spring about 1 in.

long and of the same general characteristics as that used in the angle drive is

used to form a flexible connection, or universal joint, between the motor shaft

and the piano-wire shaft. In order to make the connection it will be necessary to

solder a suitable bushing to the end of the piano-wire shaft as shown in the detail.

Then the spring is slipped over the bushing and soldered. It is not soldered to

the motor shaft, as a tight fit is sufficient to transmit the full power of the

motor.

The battery compartment of the tube is closed at the lower end with a friction

cap made of sheet brass. Two terminals and a compression spring are fitted in the

cap and the positive terminal is insulated from the metal. After wiring and installing

a switch and dry cells, test the assembly for smooth operation without the prop.

If there is any tendency toward vibration, the cause must be found and corrected

before the assembly will operate satisfactorily. Cut the prop to the size indicated

from thin sheet aluminum, give it a left-hand twist and mount on the prop shaft

with a small disk of sheet metal to which a short length of 1/16-in. brass tubing

has been soldered to form a hub. If available, a small gear wheel from a clock is

just the thing. Fit the prop with a balsawood spinner as in the details.

Flying the plane is quite simple. Once in the air it is controlled by arm movements.

Successful maneuvers depend on the application of power at the proper time and also

in the guidance of the hand and arm. Experimentation with elevator and aileron settings

will be necessary.

Posted August 31, 2024

|