|

Airplanes

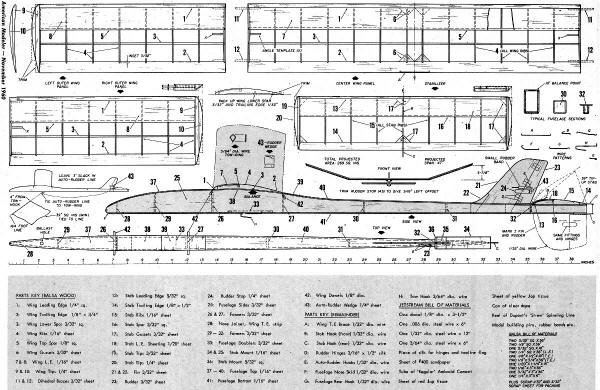

and Rockets website visitor L. Ross wrote to request that this article

featuring Warren Kurth's Jetstream A-1 towline glider be posted. I recently purchased

the November 1960 issue of American Modeler magazine, where it appeared,

so I scanned and processed the images and text. Detailed building, covering, and

flying instructions are provided by Mr. Kurth. The Jetstream's projected wingspan

is given on the plans as 47", with a wing area of 269 square inches. The fuselage

is 31" long with a balsa box construction, while the wing an tail surfaces are sticks

and sheet ribs. The wing airfoil is undercambered, which makes covering with Jap

tissue a little tricky, but the horizontal stabilizer uses a flat bottom lifting

airfoil. Instructions for making the regulation A-1 towline is even given. The model

is built so light that it requires more than 1.5 ounces of ballast to bring it up

to the A-1 class minimum of 5.08 oz (144 grams). Hopefully, Mr. Ross will

provide a photo of his completed Jetstream for posting here.

A/1 Jetstream Towline Glider

Warren Kurth's A/1 Jetstream

Winner 1959 Nationals Winner 1960 Nationals American Record

Holder Towline Glider

By Warren Kurth

Now and again there appears on the model scene a design that looks every inch

a contest winner-such as Goldberg's immortal Zipper, Hansen's '53 Nordic Winner

or King's '54 Wakefield winner. Sometimes they sport slinky Bardot curves; sometimes

no-nonsense lines like a Volkswagen. But almost without exception the world's top

contest craft seem to share an unmistakable functional beauty. Such a model is Warren

Kurth's 1960 and 1959 Nats-Winning and AMA Record-Holding A-1 towline glider-one

of the finest examples of towline design to ride the thermals for many a season.

Warren's "Jetstream" is simple and rugged. Its proportions were developed after

careful study of dozens of top glider designs-plus extensive flight testing and

contest experience. The original model was built early in '59, taking 4th in the

first contest entered (combined A-1 and A-2 event at Cedar Rapids, Iowa) and 1st

in its second contest (combined A-1 and A-2 at Chicago Midwestern Championships).

It is particularly easy for a beginner to adjust and fly.

Originally dubbed "Spike" (3-view appeared in May 1960 "A.M."), the new name

came about following the suggestion that a less vulnerable upper fin be substituted,

forward of the stab. The subsequent Mark Two version with the jet-age swept fin

is reported to give slightly better flight characteristics. It won with 11 minutes,

26 seconds at this year's Dallas Nats. The plans give both types, you take your

pick! The plans show cut-out parts arranged on 3" x 36" balsa sheets. Parts are

numbered in correct building sequence; you'll sidestep snags and finish in the shortest

possible time if you follow this procedure...

Pick out firm (but not heavy) balsa stock. Sand off any fuzz before marking patterns

on to the sheet balsa (with carbon paper or by pinpricks). Warren's original models

have no rear wing spar this is added on the magazine plans as a safety factor for

the average modeler. If you use the best wood and have already built a few lightweight

gliders, the rear spar may be omitted (but then remember not to cut the rear spar

notches in the ribs). It's important that wing tips and tail surfaces be light so

quick recoveries occur from stalls or rough air disturbance. Leading edge sheet

for flying surfaces should bend easily to follow airfoil curves.

Rub over your working drawings with a bar of soap at all rib/L.E. and rib/T.E.

joints to prevent parts from sticking to plans. Wax paper over plans isn't such

a good idea since it retards cement drying.

WING. Build the three panels separately.

Start by sanding trailing edge strips to shape and slotting them to take the ribs.

Pin down leading edges (1) and trailing edges (2) directly over plan blocking up

T.E. with scrap 1/32" sheet. Pin lower 3/32" square spars (3) over plan, packing

up with scrap 3/32" sheet balsa. Cement ribs (4) in place, using dihedral-angle

template (X) to slant four dihedral-break ribs correctly. Add top 1/8" square spars

(5); avoid distortion of ribs by not using excessive down pressure. Install center

section gussets (6). Give all joints two more coats of cement (use cement sparingly).

Allow to dry for several hours before unpinning from building board. WING. Build the three panels separately.

Start by sanding trailing edge strips to shape and slotting them to take the ribs.

Pin down leading edges (1) and trailing edges (2) directly over plan blocking up

T.E. with scrap 1/32" sheet. Pin lower 3/32" square spars (3) over plan, packing

up with scrap 3/32" sheet balsa. Cement ribs (4) in place, using dihedral-angle

template (X) to slant four dihedral-break ribs correctly. Add top 1/8" square spars

(5); avoid distortion of ribs by not using excessive down pressure. Install center

section gussets (6). Give all joints two more coats of cement (use cement sparingly).

Allow to dry for several hours before unpinning from building board.

Next, attach top wing leading edge sheeting (7 and 8) first cementing to leading

edges and front 1/8" of each rib. When dry, cement sheeting to remaining portion

of each rib and to main spars. Give sheeting joints an extra coat of cement, except

at leading edge/sheeting seams and spar/sheeting seams (which could pull sheeting

down and out of shape). Add wing tip pieces (9 and- 10); carve them to shape when

dry.

Carefully sand the three wing panels; check for weak or broken joints. Clear

dope and lightly sand with #400 paper, at leading edges, trailing edges, wing tips

and end (dihedral-break) ribs. Also dope undercambered lower rib edges (two coats).

Now line up the three wing panels, pinning center panel to building board and packing

up each tip panel 3-7/8" under the tip rib at front and rear. If facing ribs of

the three panels do not fit flush, carefully sand them to correct this.

Give each facing rib two coats of cement and let dry before finally cementing

panels together. When quite dry, cut away front and back ends of ribs, add dihedral

braces (11 and 12). Give all dihedral break joints another coat of cement, then

cement center section wire brace (A) to trailing edge.

Your wing is now ready for covering with Jap tissue (cover dry), using clear

dope as adhesive. Make sure that tissue is firmly doped to undercambered edges of

ribs. Water spray or gently dab covering with sponge of cotton to tighten it. Constantly

check for warps (twist panels in opposite direction if any should appear as tissue

dries). When dry, apply four coats of clear dope (thinned 50% with thinner); gently

sand any rough spots with #400 paper after the first coat. Dope only one panel at

a time; watch carefully for warps as the dope dries. It's good practice to pack

up each panel with scrap 1/8" sheet at leading and trailing edges and hold assembly

in place on building board with small weights while dope dries. Any trim should

be cut from colored tissue. Dyes such as "Rit" or "Tintex" can be dissolved in the

thinner if a translucent coloring is desired.

STABILIZER. Built much the same as the wing panels, except its

airfoil section is flat so no trailing edge packing is required. Start by sanding

trailing edge to shape; slot it for ribs. Pin leading edge (13) and trailing edge

(14) over plan. Add ribs (15) and 3/32" square upper spar (16), followed by gussets.

(17). Give all joints another coat of cement, allow to dry for several hours before

unpinning from building board. Add leading edge sheeting (18) and tips (19 and 20).

Finish off, cover and dope in the same way as wing; finally add the two wire hooks

(B and C) cementing them in place and covering with small patches of thin silk.

FIN AND RUDDER. For either fin hinges and auto-rudder details

are the same. Join two fin pieces (21 and 22) flat on plan. Sand this assembly and

fin (23) to sections. shown in top fuselage view-then cover each separately with

tissue. Join fin and rudder with small silk hinges (D), give four coats of dope,

add wire hooks (E) and rudder stop (24).

FUSELAGE. Cut fuselage sides; be sure they match exactly and

bottom edges are flat. The grain ends of formers and lower doubler (for tow hook)

are given two coats of cement. Bevel inside faces of fuselage sides at rear (25);

join with two formers at wing position (26 and 27). Check that sides are correctly

aligned and set flat along their entire length when placed on building board.

Now pull together and join at nose and tail (adding 28): checking fuselage top

view by placing it over plan. Add remaining formers (29 to 32), bottom doubler (33)

and stab mount (34-36 assembled flat over plan). Add top (37 to 40) and bottom sheeting

(41). Cover fuselage with tissue, apply three coats of clear dope. Cement rudder

in place, checking its alignment in both top and rear views. Add wing dowels (42),

nose skid (F), rear hook (G). Make balsa auto-rudder wedge (43). Add .096" dia.

steel wire "D/T limit."

Fasten wing and stabilizer to fuselage with rubber bands. Add lead weight to

nose compartment until model balances 2-5/8" behind leading edge of wing. If total

weight is still less than 5.08 ounces (the minimum required under A-1 rules), cut

away small piece of top fuselage sheeting under wing, fasten required weight to

inner face of this sheet and cement it back in place. Warren's original model needed

1.6-oz ballast weight under wing to bring it up to the required minimum. Carrying

ballast this way is preferable to "building up" to the 5.08 oz. A light model with

ballast has a low moment of inertia and recovers quickly from a bad launch or a

stall off the towline.

Now add towhook (H) so vertical towing portion is 1-7/8" behind wing leading

edge. This is a safe towhook location. With experience, you may like another hook

up 1/4" behind first one (see "Flying and Adjusting"). Recheck all-up weight after

several days. The dope continues to "cure" making the model slightly lighter. Add

your AMA license number to wing (minimum height 1.2"), fuselage and tail (minimum

height .4").

FLYING AND ADJUSTING. Make 164 foot towline from DuPont "Stren"

(# 12 test monofilament nylon spinning line) using the improved clinch knot shown

on instructions provided with this product. (Any braided fish line of at least 8#

test can substitute.) A quick winding reel will add a lot to your flying pleasure

and convenience. Remember to attach the 39 sq. in. flag (required in A-1 rules).

Tie the flag around the line and not the line around the flag, since the latter

method will eventually cause the line to break.

Check the model for correct balance. Steam out any flying surface warps. As a

starting point; the rudder should be offset about 3/16" to the left at its trailing

edge. Pick a calm day for the first flights. Hand glide the model over long grass.

Launching on a slightly downward flight path from shoulder level should result in

a flat, shallow glide with very slight left turn. Confine all trimming adjustments

to the tail surfaces only; do not change the balance point after this has been correctly

positioned 2-1/8" behind the leading edge. Correct diving tendencies by shimming

up the stab trailing edge 1/64" at a time. Correct stalling tendencies by shimming

up the stab leading edge in a similar manner.

Once satisfactory hand glides have been obtained, the first tow-launch may be

made. Check that the rudder is straight for towing-with the towline and wedge (43)

attached. The model is fairly sensitive to the rudder setting under tow; any offset

will cause the model to pull to one side.

Have your helper hold the model at about a 15 degree angle of attack, with the

auto-rudder line draped over the top of his hand (between thumb and index finger).

Tow directly into wind. Your helper should run a short distance until the wings

begin to lift-at which point he gently releases the model. As soon as the model

"catches the wind" and starts to "kite" upwards, slow down and ease the model to

the top of the tow. In windy weather, be prepared to run towards the model. When

the model approaches the top of the tow, slow down so that the flying speed is normal

at the moment of release (to avoid stalling). To release, run back towards the model

and throw your towing hand towards model, but do not let go of the line as this

results in a disqualified flight during a contest.

Carefully observe the flight pattern from the tow-launch. Re-adjust the stab

and rudder setting if necessary to obtain the optimum settings. For best duration,

adjust the rudder to give circles of about 100 yards diameter in calm weather conditions.

The model will turn more tightly as it enters a thermal. In windy conditions, give

a little more left rudder, to keep the model turning steadily and prevent stalling.

This is easily done by adding masking tape shims to the rudder wedge.

For flying in areas where windy weather conditions prevail, it is desirable to

move the towhook forward about 1/8" at a time, to obtain a slower (less steep) climb.

Under very calm conditions, a slightly more rearward towhook position will give

maximum possible tow altitude, by steepening the towing angle. Experienced glider

modelers may make slight balance point changes-moving it back slightly for calm-air

or forward for windy weather. The tow hook and balance locations as shown on the

plans are best for average flying conditions.

A-1 Jetstream Towline Glider Plans

(AMA Plans Service

link)

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted December 19, 2020

|