|

After moving back into our first house in

Erie, Pennsylvania, I needed to build a couple workbenches in the basement. The

ones I used when there before were made from Gorilla Rack metal frame parts and

had been left at the previous house. Besides, I really prefer a good, sturdy wooden

framed workbench with doors and drawers. Also, after using many types of materials

as a work surface, I have found that a good interior grade plywood (7-ply or greater)

works best. It is very stiff and durable, and does not puff up and distort when

water is spilled on it. After moving back into our first house in

Erie, Pennsylvania, I needed to build a couple workbenches in the basement. The

ones I used when there before were made from Gorilla Rack metal frame parts and

had been left at the previous house. Besides, I really prefer a good, sturdy wooden

framed workbench with doors and drawers. Also, after using many types of materials

as a work surface, I have found that a good interior grade plywood (7-ply or greater)

works best. It is very stiff and durable, and does not puff up and distort when

water is spilled on it.

Vertical frame members all cut on a jig to assure matching components.

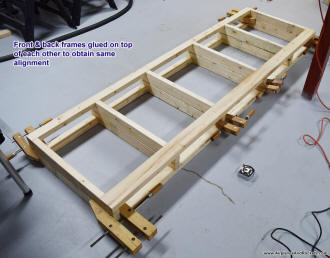

Frame fronts and backs assembled and glued on top of each other

to assure mutual alignment.

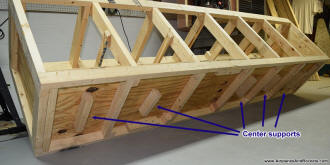

Supports added to bottom surface of plywood so heavy loads don't

make it sag.

One criterion was that the standard 24" depth (half a

4' x 8'sheet of plywood) would be insufficient for the workbench that

would hold benchtop power tools, since at least 4" - 5" of the back of it is normally

taken up by parts bins and soup cans with things sitting on and in them. So, even

though it meant having to buy more plywood, I decided to make that workbench 28"

deep. The other, which would be the primary project workbench, is 24" deep and 120"

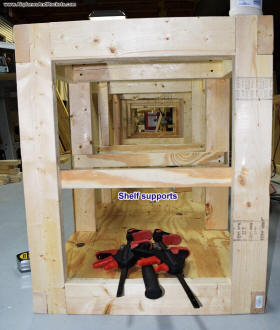

long (for holding the radial arm saw). A separate shelf unit was built for the back

of the 24" deep workbench so that it would retain a full 24" work area. It has been

a very nice convenience.

Framed doors and drawers were built to add a little class to the project, rather

than just cutting flat plywood panels for everything. The glued-on pine frames add

a lot of rigidity to all. Standard self-closing cabinet hinges used on doors. Heavy

duty ball bearing slides used on drawers.

I did not draw plans for these workbenches, so the best I can offer is these

few photos of the building process. If you look closely, you will see that none

of the screws were installed from the outside where they would be visible. Also,

all joints were glued with Elmer's Carpenter's Glue. These are by far the nicest

set of workbenches I've ever had.

End view of plywood internal shelf supports.

Posted October 3, 2015

Other Woodworking Tips & Projects:

|