[Table

of Contents]People old and young enjoy waxing nostalgic about and learning some of the history of early

electronics. Popular Electronics was published from October 1954 through April 1985. All copyrights (if any) are

hereby acknowledged.

See

Popular Electronics articles

on aircraft modeling. See all articles from

Popular Electronics. [Table

of Contents]People old and young enjoy waxing nostalgic about and learning some of the history of early

electronics. Popular Electronics was published from October 1954 through April 1985. All copyrights (if any) are

hereby acknowledged.

See

Popular Electronics articles

on aircraft modeling. See all articles from

Popular Electronics. |

Bill Winter is one of the best-known names in the aeromodeling realm

since he has been around writing columns on modeling events, construction,

flying, and product features, serving as editors of modeling magazines,

and participating in modeling events throughout the country since

the middle of the last century. He went above and beyond the call

of duty in his attempt to introduce people to the model aircraft

and model rocketry hobbies. This particular article is one of a

handful Bill wrote for Popular Electronics magazine in

the 1950s and 1960s. An amazing transformation has occurred in the

radio-control aspect in that when this article was published, participation

required knowledge of electronics, a larger hobby budget than your

average modeler, and a willingness to be continually battling problems.

R/C Reliability Escapements and Batteries

By William Winter Editor, "Model Airplane News"

Concluding

last month's discussion of reliability, that taken-for-granted device,

the escapement, had our attention. In the author's log, covering

15 radio control airplanes and thousands of flights, the escapement

was found to be second only to the relay as a cause of erratic control.

The point was made that the escapement should be considered as a

relay, since it has pull-in and drop-out currents which, aside from

the mechanical features, require observation, occasional adjustment,

and an accessible and removable installation that enables convenient

maintenance. Do not bury the escapement in a "blind" installation. Concluding

last month's discussion of reliability, that taken-for-granted device,

the escapement, had our attention. In the author's log, covering

15 radio control airplanes and thousands of flights, the escapement

was found to be second only to the relay as a cause of erratic control.

The point was made that the escapement should be considered as a

relay, since it has pull-in and drop-out currents which, aside from

the mechanical features, require observation, occasional adjustment,

and an accessible and removable installation that enables convenient

maintenance. Do not bury the escapement in a "blind" installation.

How the escapement works has been described in earlier articles

of this series, as well as in Mr. Safford's articles in this magazine.

Our concern now is how to keep one working. Properly installed and

regularly checked, the escapement is reliable. Any new escapement

should be examined and bench-tested before installation in the plane.

Howard Bonner, whose SN and compound escapement types are familiar

to all R/C modelers, states that the overlap of the revolving arm

or claw, on the pawl, should be 0.015 to 0.020, armature pulled

in. With the armature released, the claw should barely clear the

pawl. Also, when armature is pulled in, the claw should barely clear

the neutral pawl position. These values apply approximately to the

other familiar makes of escapements.

|

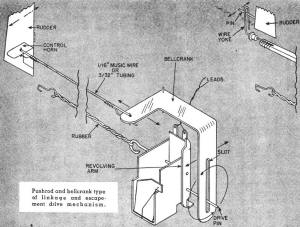

Pushrod and bellcrank type of linkage

and escapement drive mechanism.

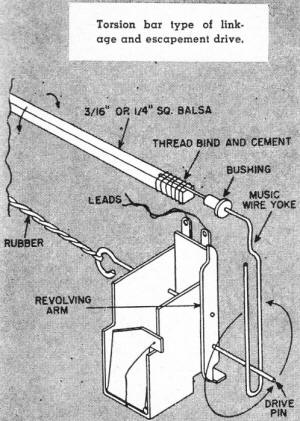

Torsion bar type of linkage and escapement

drive.

|

If the escapement functions suitably when hooked up on the bench,

leave it alone; the above figures are given as a rough guide in

the event that the item skips or sticks, requiring adjustment that

is unlikely when new. After operating the escapement perhaps 100

times on the work bench, examine it closely for burrs that might

develop where claw and pawl meet. The tiniest burr can prevent the

escapement's working in the air. Usually the escapement so afflicted

functions while the engine is running, but when the motor stops

and vibration disappears, response to a transmitted signal does

not occur. Sometimes new escapements develop burrs quickly, but

once smoothed off will function properly for long periods of time.

Set up batteries similar to those in the plane, also the same

size rubber strand wound to 20 per-cent excess of a single row of

knots (not counting the first row of turns). It is vital to check

the spring tension. Does the escapement always release when the

rubber is fully wound? Does the escapement always pull in and work

easily under simulated service conditions? One excellent way of

checking is to hook up a set of batteries with a potentiometer in

order to vary the voltage available to the escapement magnet, Increase

voltage gradually until the escapement armature pulls in. Just as

important, note the voltage at which the escapement releases. This

was the most important lesson learned by the writer in the 1954

flying season.

The escapement should never require more than 2 1/2 volts to

pull in and should not require a cutting off of current in order

to release. First, the pull in. Under load, two new 1 1/2 volt pen

cells in series drop off to 2 3/4, volts. As the no-load voltage

decreases with use, the voltage then available under load may be

less than the voltage required to pull in the escapement. Once during

a demonstration, the writer installed a new, unchecked escapement

and immediately lost control of the plane during the glide. A check

revealed that the escapement required 2 7/8 volts to pull! It is

best, therefore, to allow an adequate margin for falling voltage,

especially under load, by adjusting the escapement (its spring tension

is increased or decreased) to pull in at 2 to 2 1/4 volts.

Why is drop out so important? If spring tension is too low, the

flow of current '\has to be cut off to allow release of the escapement

armature. This is a timely tip that in the air the escapement may

not release. Many a crash has been attributed to interference, sticking

relays, etc., when the escapement was out of adjustment. The difficulty

is that if the condition is marginal, the escapement may appear

to function properly after the accident, so that cause of the accident

may be undetermined. Eventually, the spin-in will be repeated. Sometimes,

the plane has a mysterious tendency to come out of a turn very slowly

after the rudder is released or to continue overbanking momentarily

after the rudder goes back to neutral. This can be caused by a sticking

relay, but also suspect that escapement.

It has been found that if the escapement will release with current

caused by 1/4 volt flowing through the coil, it should release reliably

by spring tension in the air. The current is a measure of spring

tension.

Mounting affects an escapement. Do not screw an escapement base

tightly to a slightly warped piece of plywood. The frame bends,

throwing adjustments out. Then the modeler may file the end of the

revolving arm to make it shorter. Loosen the escapement and the

frame springs back into alignment. Now the gaps are too big and

the escapement is needlessly junked. So the mount must be firm (if

the escapement does not incorporate its own mount), never less than

1/8 inch thick plywood with the long edges reinforced with balsa

strips, and it should also be warp free.

It is important to use the proper rubber strand for the escapement

drive power and the correct voltages. The type of linkage affects

the required size of rubber. There are two types of familiar linkages.

First, the push rod connected between the rudder horn and the bell

crank, converts the rotary motion of the escapement drive pin into

linear motion. The second is the torsion bar, which is rocked back

and forth by the rotation of the escapement drive pin. The push

rod arrangement increases the load on the escapement, especially

during maneuvers (centrifugal force multiplies the weight of the

rod) when the entire weight of the linkage may have to be lifted

by the actuator. The torsion bar is easier to move, does not overload

the escapement and, therefore, favorably affects the size of rubber

which is required, in addition to escapement adjustment and operating

currents.

|

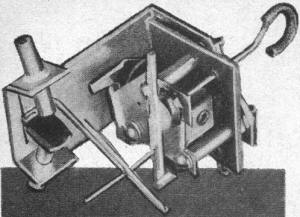

In this self-neutralizing escapement the mechanism is

also used to cover and uncover air bleeds in the fuel line

to control the motor.

|

With self-neutralizing escapements, 1/8 inch rubber has been used

with both push rod and torsion bar, although, in the author's opinion,

it is decidedly marginal in the case of the push rod, particularly

on a cold day when rubber loses much of its natural vitality. Therefore,

it is better to use 3/16 inch rubber with push rod deals. When using

3/16 inch rubber, allow 20 per-cent extra length over and above

the distance between hooks. This prevents too much tension being

placed on the escapement thrust bearing which could cause a jamming

action. The compound escapement should never be used with 1/8 inch

rubber with a push-rod linkage. The reason is that the compound

incorporates a rattle wheel to slow down the action of the escapement

and allow the man on the ground enough time to get off the required

number of pulses necessary for its operation. So the compound requires

more drive power than the self-neutralizing escapements.

Some builders claim that the flier must have a sense of timing

to pulse the compound (one, two, or three signals, depending on

the desired control). Therefore, they claim it is better to use

the weaker, 1/8 inch rubber to slow down the escapement so that

the flier can keep up with it. That is poor advice. The compound

can hang up when powered by 1/8 inch rubber, if only due to the

drag of the electrical contacts in the third control position. Actually,

it is better and easier to operate the compound with 3/16 rubber,

when the unit works faster instead of more slowly. With the 1/8

inch rubber, timing is important, because it is possible to pulse

too fast and pick up the wrong control. With the 3/16 inch rubber

it becomes impossible to pulse too fast with a Microswitch held

in the hand. At the same time it is not hard to pulse fast enough,

especially after a few practice dry runs on the bench. Even a mechanical

ground control unit will not time properly the 1/8 rubber driven

compound. As to reliability, the compound is often criticized, but

one of the author's compounds has given trouble-free operation equivalent

to three self neutralizing units.

It is frequently argued that the compound does not have the ability

to hold the rudder over when air speed picks up or to hold the plane

in a prolonged spiral, especially in the direction of the control

(usually left rudder) that requires two pulses. Supposedly, the

compound is not effective on big, heavy, fast machines. The truth

is that the compound is suited for all installations, provided an

aerodynamic surface (see drawing) is used along with the3/16 inch

rubber drive.

Blaming escapement ills on batteries is both commonplace and groundless.

People are forever putting 4 1/2 and even 6 volts on a 3-volt escapement.

Not only is this unnecessary under any circumstances, but it leads

to further complications. To begin with, battery drain is increased

greatly with higher voltages when the resistance of the coil remains

the same. This is a basic law of electricity. Therefore, the batteries

run down faster, not more slowly, when voltage is stepped up. A

5 ohm escapement which might function for several flying sessions

on 3 volts, may make only one long flight on 6 volts! Battery life

is increased by hooking batteries in parallel, not series. Most

planes can carry four pen cells, instead of the standard two, for

escapements. Two pen cells may give a dozen good flights, depending

on how many times the control is applied and how long it is held

on. Planes with slow response are rough on batteries all down the

line, even in the transmitter. Excessive voltage on many escapements

builds up a residual magnetism which can cause the armature to stick

in the control position. Higher actuator voltages accelerate damage

and dirt on the relay contacts.

With some builders, batteries may be the second or even first

source of trouble. In the writer's log they happen to be third,

mostly due to odd and unexpected failures, such as one abrupt failure

resulting from the battery having been dropped by a clerk. A connection

between cells gave way. This suggests care in the handling of "B"

type batteries.

Choose battery sizes that provide adequate life and reserve,

unless, of course, the plane is a midget. For example, two pen cells

on filament will give an afternoon's flying on a single (gas) tube

receiver. Such receivers have even been flown on one pen cell, but

if the plane will carry one or two medium flashlight cells, it is

an unwise risk. A two (gas) tuber will operate on two pen cells

for a busy half-day flying session, but two mediums would last for

weeks. Similarly, why fly on 22 1/2 or 30 volt hearing aid "B" batteries

(in series for 45, 67, 60 volts, etc.)? A single Burgess XX-30 or

K-45 or the equivalent in other brands will last for weeks, if not

months. The typical transmitter will operate for at least a season

on Burgess M-30's or larger (or the equivalents). Hearing aid "B"

batteries certainly are not desirable for long term results with

hard tube receivers that idle at 3 or 4 mils. Two mediums on an

escapement may last a summer.

Possibly the gravest error made by the beginner is to measure

voltages without placing a load on the batteries. The transmitter

should be checked with filament turned on, Microswitch closed for

"B's." It will be noted that "B" batteries may drop several volts

under load, but this is normal. On the other hand, a drop of 10

volts or more from the initial reading (not new voltage necessarily)

under observation means that the batteries are weak. Hold the meter

probes in place for 5 to 10 seconds and watch for a slight, steady

falling off in voltage. The battery is no good. Do not operate anywhere

near the minimums specified by the radio manufacturer. The writer

discards flight "A" batteries that read 1.4 volts or less under

load, when 1.5 volts is the normal filament voltage. The voltage

can drop further in the air and 1.3 volts is the safe minimum.

For 3 volt escapements, a bitter-end 2 1/2 volt minimum under

load is desirable, unless the escapement happens to be one that

works on 1.5 volts, as does the Macnabb Citizenship. After a 67

volt "B" battery drops 5 volts to about 62 volts, there is no percentage

in continuing it in service. Battery costs are low compared with

the total cost of plane, radio, engine.

In cold weather, allowance must be made for a falling off of

voltage due to temperature. Some modelers keep batteries in a warm

place, as in the pocket or on a car heater. Obviously, this is inconvenient,

but batteries should be allowed to recuperate between long flights.

It is a good rule to allow the batteries to rest for a period twice

as long as the last flight. Between flying sessions, batteries recuperate

so that they almost regain the normal new voltage. After that, they

should be checked after every few flights.

Make it a rule to check batteries before going out to the flying

field. If they are down to a serious degree, install new ones and

enjoy an outing free of concern.

Posted March 14, 2015

|