|

S.C. Smith's cover drawing

for this 1956 issue of Air Trails magazine is an enhanced version

of Wayne Schindler's ducted fan Saab Draken 210 free flight [semi] scale model

airplane. Back in the day, there were no commercially available ducted fan

units, so they needed to be designed and fabricated by the builder of the model.

The computer optimized ducted fan units we have today are matched to the

powerplant, which much more often that not is a brushless motor. I don't know if

anyone makes a ducted fan for glow fuel engines anymore. This Saab Draken 210

used a Cox .049

Thermal

Hopper glow engine, which was capable of turning 10,000 rpm. 1956 is the

year Cox introduced the Babe Bee .049 was introduced, but might not have been

available at the time. It could do 13,500 rpm on 15% nitro fuel, so could have

added significant thrust to the ducted fan unit. The six-blade, three-inch

diameter fan was not enclosed in a tightly fitting duct like modern fans are.

This new 50 mm diameter (~2") electric ducted

fan (EDF) puts out 770 g (1.6 lb.) of thrust on a 3-cell LiPo battery.

Ducted Fan Saab Draken 210 Free Flight Scale Plane

The Flying Sensation of the National Contest!

Thousands saw

this high-climbing craft perform at the Los Alamitos championships!

Its real

takeoffs - unassisted and from standing start - drew cheers from all.

By Wayne Schindler

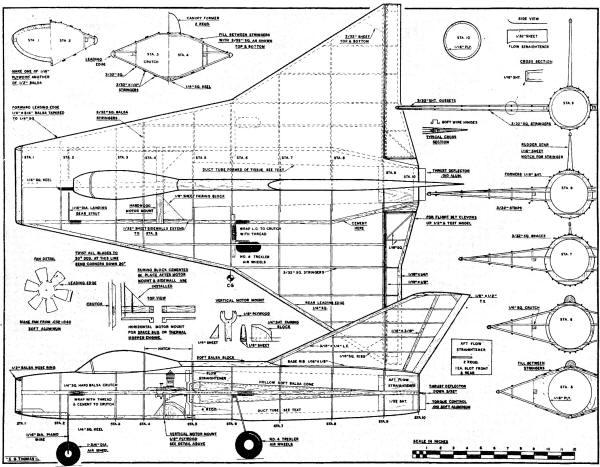

Study the drawings and read these instructions carefully before beginning construction

of this model. It is necessary that you follow the step-by-step procedures as outlined

to eliminate engine installation problems.

Cut the 1/4" sq. balsa crutch and forward keel pieces to length as indicated

on plans and glue together. Mark all station positions on them. Now build stations

2 to 4 of 3/32" sq. balsa. After cutting out the center sections of the rear stations

pin them over the layouts and build the extensions in the same manner as the forward,

stations. Before lifting them from the layouts glue the rudder spars on to guarantee

accurate alignment.

Slide stations 9 on the crutch pieces to approximate position, then 8, 7, 6,

etc. Leave stations 1 and 10 off. Prop the crutch pieces on blocks over the layout

so that the ends are square and the sides are parallel. Put weights on them to hold

them in place. Now relocate the stations in their proper positions and glue in place.

When dry install stations 1 and 10, and then the forward keel. The forward leading

edge strips are glued in place after beveling the tips of the stations to receive

them. Using the same procedure assemble the rear leading edges. Slide the top center

stringer through the rudder spars and glue in place between stations 5 and 10; also

the bottom center stringer.

The next step is to make and install the duct unit. Start by cutting a sheet

of Silkspan 11 by 18 inches and doping it to a sheet of glass with fuel proof dope.

When almost dry slide it from the glass and let finish drying. Replace it on the

glass and dope on another piece of Silkspan cut cross-grained; continue this procedure

till five sheets are bonded together. After the last coat of dope allow to remain

on the glass overnight till completely dry. Trim to size of 18" long by 10 3/4"

at front by 8 1/4" at rear. Roll into a tube about 2" in diameter and slide into

the model from station 10 to 5 with the 10 3/4" end forward. Release and allow to

expand. Align the open edge 1/4" off center line of fuselage, allowing overlap in

front and rear. Glue about one inch of this edge to stations 5 and 10 only. When

set glue another inch in place, and so on till the entire circumference is glued

in place. Next glue the seam in place at the other stations, observing that the

tube touches the formers of the stations. Now spot-glue the rest of the stations

to the tube. Trim the excess tissue from the front and rear and the duct is finished.

Just about the most jaunty job around at the 1955 National modelplane

championships. SAAB was about most popular, too!

Ducted Fan Saab Draken 210 free flight scale model plane side

view.

Ducted Fan Saab Draken 210 free flight scale model plane rear

view.

Author-designer-experimenter Schindler with first test version

of his delta wing free flight ducted fan. Craft is said to be first ducted fan to

take off under own power regularly.

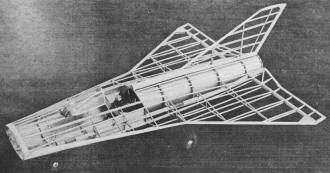

Ducted Fan Saab Draken 210 free flight scale model plane uncovered

framework.

Insert the soft blocks between the elevons and duct at the rear of the model.

Install the remaining stringers. Assemble the leading edge, tip, and trailing edge

of the rudder on the model aligning with the spars. Glue on the 1/16" sq. rib formers.

Assemble the aft flow straighteners, slide them into the duct from the front

and check for fit. They should slide back to station 10. The cone as shown on the

side view is made of soft balsa and is 1 9/16" diameter at its maximum point. After

shaping cut the block in half and hollow out as indicated. Reglue together and cut

two slots in the rear end 3" long and perpendicular to each other to receive the

aft flow straighteners. Make and install the forward flow straighteners on the cone

parallel to the aft flow straighteners, and with their leading edges curved as shown.

Slide the cone into the duct and over the aft flow straighteners to check the fit;

the leading edges of the forward flow straighteners should stop at station 5. Remove

the entire unit and assemble, sand and dope till smooth. Replace in duct in proper

position and glue. Use fuel proof dope and cement throughout.

Fit the 1/32" sheet sidewalls between station 3 and 5, gluing to upper and lower

stringers as well as to crutch. The nose gear is split in the center of the axle

to allow changing wheels. Use Trexler #4 airwheels; they are light and sturdy. Only

precaution is to deflate them when not in use., Install the thrust and torque deflectors

as shown on the plan. Be sure to have about 3/32" down thrust.

Carefully tap the three mounting holes on the Thermal Hopper engine with a 4-40

tap. Screw to horizontal and vertical motor mounts, using 4-40 machine screws with

the slot end facing forward. Cut a 1/8" by 1/2" slot in the balsa side-walls as

shown on side view to receive the horizontal mounts. Slide the mounts in place and

slip the vertical mount over the forward keel. Align the engine crankshaft with

the center of the cone. Now glue the mounts in place. When dry remove the engine

and glue in the horizontal and vertical fairing blocks. Sand entire unit thoroughly

and dope well, using fuel-proof dope.

The elevons are built on the plans using 1/16" by 1/8" balsa laid flat for the

leading edges and ribs with the trailing edges of 1/16" by 1/4". When dry glue on

1/16" by 1/8" on edge over the leading edges and ribs, top and bottom. Spot glue

the completed elevons in place on the model and trim to shape shown on plans. Use

soft wire for hinges as indicated.

On our model the underside of the nose back to station 4 was covered with 1/32"

sheet balsa for additional strength. Sand the entire model smooth and cover with

lightweight tissue. Cut out the tissue between stations 4 and 5 top and bottom as

shown on photos for additional air inlets. Also directly under the engine. The completed

model should weigh about 10 1/2 ounces. We used hard balsa throughout.

All flight adjustments are made with the thrust deflectors and elevons. The elevons

should be up about 1/2", the thrust deflector down about 3/32", and the torque deflector

right about 1/16". Install that wonderful Hudson Miniatures Super-Self Starter instead

of the conventional pulley. One of the small Jim Walker balloon tanks works best

in the model instead of the regular tank. It prevents engine stoppage due to surges

and allows no air bubbles in the fuel line. Just lay the tank in the bottom of the

fuselage. Refueling is accomplished by removing, reinstalling tank from bottom of

fuselage.

Fuel up - attach the battery leads - engage spring and back up about one turn

and let her go. This model is remarkably stable when balanced at the center of gravity.

Ducted Fan Saab Draken 210 free flight scale

model airplane Plans before cleaning up. Ducted Fan Saab Draken 210 free flight scale

model airplane Plans before cleaning up.

Ducted Fan Saab Draken 210 Free Flight Scale Plane Plans (cleaned-up)

Full-size plans for SAAB Draken are part of Group Plan #256A from Hobby Helpers,

770 Hunts Point Avenue, New York 59, N. Y. (50¢).

Posted February 10, 2024

|