|

When I run across articles

like this "CAR: Coupled Aileron Ruddered System for Radio Control" which

appeared in the 1960 Annual issue of Air Trails magazine, I

am in awe of some people for the genius, creativity, and willingness to do the

hard work involved in advancing the state of the art in a given field. Not

surprisingly,

Maynard Hill is the author and progenitor of this - at the time -

breakthrough method of combining aileron and rudder control to enable at least

some semblance of coordinated turns with radio controlled model airplanes.

Mr. Hill was a metallurgist in his day work at

Johns

Hopkins' Applied Physics Laboratory. Distance and altitude records for R/C

models were among his many accomplishments. Looking at the complication of the

electromechanical coupled aileron-rudder control system makes me appreciate

modern servos and digitally proportional R/C equipment. The mechanical linkage

between the pseudo-servo motor-gear unit and the ailerons is akin to dial cords

in radios connecting the tuning dial to the variable capacitor in the oscillator

tank circuit. Any slippage in the non-geared interconnection would leave an

offset between the aileron throws. I'm guessing Maynard had that all figured

out.

CAR: Coupled Aileron Ruddered System for Radio Control

By Maynard L Hill By Maynard L Hill

Imagine yourself at the stick of an R/C plane that's up there 200 feet flying

upside down. And further ... suppose it's almost as easy to fly inverted as right

side up! Call a right hand circle to yourself. Put the stick over a bit to the right

and a bit towards down and around she goes in a perfectly coordinated upside-down

turn. When you've finished the turn, put the stick back to neutral. Away she goes,

straight as a scared turkey and still on her back. Hmm - pretty easy.

Let's try that AMA pattern upside down now. Remember, up is down and down is

up. Here we go now. Straight out! Procedure turn. Figure of 8! Rectangle! By golly,

we did it! It's really pretty easy so long as we remember the elevator is backwards.

Say! We ought to be able to do an inverted buzz job! Pull a bit of up into the elevator

and down comes the nose. Man, she's coming down! The wings are tipped a bit to the

left-crank the stick a bit over to right to level them.

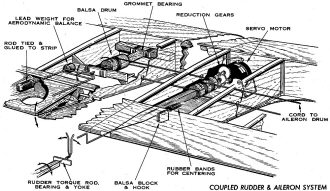

CAR: Coupled Aileron Ruddered System for Radio Control mechanical

drawing.

Oops! There's the ground in the bottom of your eye. Start pressing down on the

stick. Slowly now - don't panic. The ground isn't hard if you don't hit it! More

down, a bit more and there she is! Level, upside down and twenty feet off the deck.

Concentrate! Up is down and down is up! Stay steady on the stick and just let her

ride across the field. Enough! Enough! Push full down and around she goes in half

an outside loop. It's right side up and safe again - but it sure was fun being unsafe!

When you get that airplane back on the ground you'll hear some guy (who really

meant it as a private remark but couldn't keep his volume turned low) say, "Hey

- look. there! Those surfaces are wiggling! That must be dual proportional! Impossible

- it's got ailerons on it." Well, when the truth comes out, the airplane was not

really triple proportional-it was plain old simple TTPW with coupled rudder and

ailerons.

The coupled rudder-aileron system has been used on several full scale aircraft

as a method of simplifying the job of flying. The real Ercoupe, for example, has

a simple wheel for turn control which applies just the right amount of aileron and

rudder to provide a coordinated turn. The airplane is advertised as being spin-proof,

stall-proof, 100-proof and is just the right thing for 80 year old widows to fly

to church on Sundays.

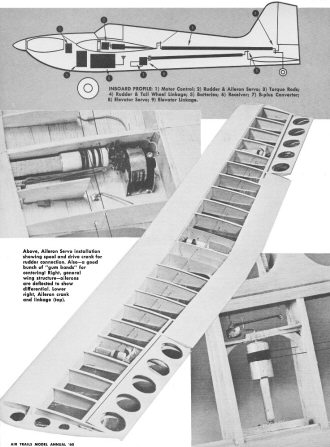

Inboard Profile: 1) Motor Control; 2) Rudder & Aileron Servo;

3) Torque Rods; 4) Rudder & Tall Wheel Llnkage; 5) Batteries; 6) Receivers;

7) B-plus Converter; 8) Elevator Servo; 9) Elevator Linkage.

Above, Aileron Servo installation showing spool and drive crank

for rudder connection. Also - a good bunch of "gum bands" for centering! Right,

general wing structure-ailerons are deflected to show differential. Lower right,

Aileron crank and linkage (top).

The coupled aileron-rudder system (let's call it CAR from here on) was not tried

in R/C planes until about two years ago. This, of course, is not surprising for

it's a rare R/C'er who wants to build a stunt proof model. However, early in 1958

the light dawned almost simultaneously on Jim Martin in Tennessee and yours truly

in Pittsburgh. The Ercoupe is not stunt-proof because of the CAR system - it has

stops on its control surfaces that just won't let you put the surfaces out far enough

to let you get into trouble. And so we tried it and found that R/C airplanes with

CAR can indeed be fully aerobatic, and at the same time, somewhat easier to fly.

The CAR system has one very decided advantage in addition to its ease in flying.

It takes only two channels to run both the rudder and ailerons instead of the four

normally used in multi-reed units. For this reason, it has been a real boon to dual

proportional fliers who just do not have two more channels to pour into ailerons.

(I define TTPW as a five channel unit - four individual audio waves and one carrier

wave.) The system is also beginning to appear on reed airplanes of fliers whose

pocketbooks can reach only to five channels. Actually, if properly applied, the

CAR system can make the five channel rigs fully competitive with their longhaired

offspring that play Brahms symphonies. It wouldn't surprise me to someday find an

industrious modeler with a 12 reed unit who decided to couple his ailerons so he

could hook up crop dusting equipment.

In this report, I'm going to wander through some of the experiences that I and

some modeler friends have had with CAR systems. Being a long time dual proportional

flier, it is natural that my experiences and observations have been limited mainly

to this type of control. But it will be fairly obvious that a great deal of the

knowledge we've gained will be applicable to five channel or multi-channel reed

units.

The first and most natural question about the coupled aileron-rudder system is

what type of airplane is best suited to it? Should it be a hi-wing, shoulder, mid,

10 or hi-wing job?

The first attempt I made at the system was on a plane called the Bulgy-Bug. This

was essentially a 7 foot copy of Walt Good's Multi-Bug with slight modifications

on dihedral and decalage. It was made large because the original intention was to

equip it with two WAG dual outfits. I expected to hog the entire 6 meter band to

fly it. However, before all the gear was put together, I decided to try coupling

the ailerons to the rudder. The experiment proved so satisfactory that I still have

only one receiver. This high winger was quite easy to fly inverted and performed

very decent axial rolls. The true axial roll with a constant roll rate is one of

the hardest maneuvers in our present AMA pattern and relatively few models will

do them perfectly. (I asked the editor to permit me to express an occasional opinion

on how AMA stunts should be judged, for I have a very strong opinion that axial

rolls should not only be axial but also at a constant roll rate!) The Bulgy-Bug

came pretty close to giving the impression it was strung on a wire during rolls.

A bit after the Bulgy-Bug, Bob Kirkpatrick of our Monroeville Model Flyers Club

handed me the stick of an Astro Hog with coupled proportional ailerons. This was

indeed a thrill for it did some of the most beautiful take-offs I've seen and was

extremely smooth in its flying characteristics. The aileron throw was somewhat less

than that normally obtained with reed servos and because of its weight and somewhat

weak proportional servos it rolled so slowly that three consecutive rolls would

have required a 50 watt transmitter and binoculars! However, it was clearly demonstrated

that CAR would produce well-coordinated turns and rolls. But it was also clear that

it would take a husky servo to push the extra weight around.

The summer of 1959 brought out a few shoulder wingers and several new varieties

of high wingers. While most of the high wingers were comparatively easy to fly inverted,

some had a tendency to barrel roll instead of true axial rolling. This is not an

inherent characteristic and it can be cured by the proper amount of coupling and

dihedral.

From an aerodynamic viewpoint, both in practice and theory, the mid-wingers or

shoulder wingers appear to be least sensitive to variations in the amount of rudder

and dihedral. Furthermore, the linkages and radio gear all fit comfortably in the

fuselage-of a shoulder-winger.

To the best of my knowledge, the CAR system has not yet been tried on a biplane,

but in view of the fact that all the other three configurations can be made to work

quite satisfactorily, it seems highly probably that the biplane will also work well.

The next major question about the system is what is the best method of coupling

the ailerons to the rudder. Another way to ask this is ... should the rudder and

ailerons be powered by separate servos or can they be mechanically linked to a single

servo? I t turns out that it takes surprisingly little servo power to steer a plane

with rudder and therefore the general answer is that if you have a servo of sufficient

torque to drive the ailerons, this servo will not notice the additional, load of

the rudder. In most cases then, the single servo will be sufficient. This would

certainly be the case with conventional reed operated servos where the full torque

of the servo is available through the entire travel of the linkages. However, in

the case of proportional pulse servos, which generally have smaller torques, the

situation is somewhat more complicated. A small discussion of proportional servos

is in order. This applies to both aileron and elevator servos.

There are two important response requirements of a proportional servo that must

be met before successful aileron operation can be obtained. The first is that the

time required to travel from full left to full right (and vice versa, of course)

must be less than one second. This response is controlled entirely by the speed

of the motor and the amount of gear reduction employed. The second response of importance

is the time required for the servo to move from full left (or right) to neutral

when the stick is snapped correspondingly. It turns out that this response is controlled

almost entirely by the strength of the spring centering employed. I use the well-established

method of rubber bands attached to a hook on the motor shaft for spring centering

and I have been accused of owning stock in a "gum band" factory because of the number

of occasions I've said, "You must have lots of gum bands to get a good proportional

servo."

This second or "neutral seeking" response is a bit more difficult to ex-plain

than the first, but I think it can be readily understood if we consider what actually

happens when we snap the stick from full left to neutral. In the full left position,

we are applying full torque of the motor because the relay is almost continually

closed to one set of batteries. Now, if we snap the stick to neutral the relay sends

equal pulses of positive and negative voltage to the motor. From these equal pulses,

there is no net force or torque driving the servo to neutral. If in fact, we omitted

the spring centering and performed the stick motions from full left over to neutral,

instead of moving to neutral, the servo would simply start to pulse about the full

left position. It would not move to neutral when we move the stick to neutral. So

actually, it is the "gum band" that brings - the servo back to neutral and the motor

has nothing to do with it. (Actually, this is not strictly true ... the pulses wiggle

the gears and thus eliminate sticking friction, but it is really the "gum band"

that is responsible for the servo returning to neutral.)

I have heard a number of fellows (who, incidentally, often have poor luck with

proportional) say that in order to get back from left to neutral quickly, they must

apply some right control momentarily. This condition leads to a tendency for the

airplane to oscillate due to overcontrol by the pilot. Such oscillations can be

very bad during landings and of course they would be completely intolerable in inverted

buzz jobs. A servo with this kind of response is also extremely difficult to fly

in gusty weather. A small bump by the wind stimulates the pilot into an overcontrol

which looks like a still bigger bump which leads to bigger overcontrol which usually

ends by a bump into the ground.

The requirement for this "neutral seeking response" is again that the servo must

come from full position to neutral in less than one second. This one is a bit harder

to measure than the "full motion response." A simple way to measure both response

times simultaneously is as follows. You simply take the stick in your hand and sweep

from full left to full right at a rate of about once each second. Don't snap the

stick from full left to right, move it at a smooth sweeping rate. The surfaces should

be in the same relative position as the stick at all times. If you stop the stick

at any position during the swing, the surface should position itself instantly and

wiggle about that position. It should not gradually crawl to a new position after

you stop the stick.

If the surfaces stay with the stick at all times during this test, both response

times are sufficiently rapid to learn to fly without getting yourself into trouble

because of poor servos (which incidentally, produce a high mortality rate among

beginning dual proportional fliers). If you use electrical centering on servos -

as has been suggested in various radio columns, be sure to give them this response

test before flying. In general, it is difficult to get satisfactory response times

unless some sort of transistor gain circuits are employed.

What do you do in the event the servo lags during your response test? the answer

is simple! You must put more "gum bands" or spring centering on the servo. Gum bands

may also be put on weak electrically centered servos. This will of course result

in what may be another undesired condition in that the servo will no longer drive

the surfaces to the full deflection you require for outside loops or fast rolls.

Actually, this is a good condition to use during your first flights on any airplane

- you will have snappy servo response and you won't have enough control action to

get into trouble. You will be in an Ercoupe, so to speak. Later on, when you've

gotten familiar with the plane and want to really rack if up, the only way to get

back the lost deflection is to increase the torque at the servo motor shaft. This

can be done either by increasing the voltage, of the servo batteries or by rewinding

the servo motor with larger diameter wire. You'll find that once you've put on enough

"gum bands" to give the proper response times, these will not be significantly altered

when you increase the motor torque.

A trick that has been used in connection with this torque response problem is

to use some sort of non-linear spring system in which the leverage of the spring

decreases as the surface moves away from neutral. Properly rigged and in the hands

of an experienced pilot, such systems can provide a little extra performance. However,

it is my personal belief that this is a poor approach to the problem for the simple

reason that if you have built a complete dual proportional rig, you have usually

gone to considerable trouble to get an electronic system whereby the receiver relay

follows the stick in true proportional fashion. It seems rather ridiculous to now

completely distort this in the servo. Actually, it is more than ridiculous - it

is dangerous! Most all systems of non-linear centering result in "humps" in the

servo response and these can cause oscillating approaches in landings, slow recovery

from violent maneuvers, even crashes!

The question of how much torque is required on the CAR servo can be answered

in reasonably straightforward fashion. If you presently have a proportional elevator

servo which will produce outside loops and still permit you to fly smoothly straight

and level, this servo is adequate to drive the CAR. Notice that I put the restriction

on it that you must be able to fly smoothly. You can get outside loops from a proportional

servo by cheating on the "gum bands", but when you cheat there you usually lose

the smoothness. When you install this servo in the aileron position, put just a

bit more spring centering on it than you did when you used it for elevator. The

ailerons require somewhat less deflections than the elevator and the gain you get

in response time will pay off in that inverted flight.

For those who may be just venturing into the pulse proportional servo game, I

can say that the 1.3 volt Minitone SRM33032 motor when geared down about 20 to 1

is an excellent servo for operation on 2 Nicads on each side of center. It will

draw about 200 ma in neutral and will outside loop most any 6-lb airplane. With

this combination, you put enough "gum bands" on a hook on the shaft so that the

output gear turns just 180 degrees. Incidentally, this is an impressive bundle of

5 or 6 No. 16 rubber bands. This servo will have response times of the order of

d1/2 second. The construction of such a servo was described in Everything Under

Control in the March 1959 American Modeler.

There are a number of types of Minitone motors available and it should be clearly

stated that you must have one rated for 1.3 volts. This particular model is not

readily available to hobbyists. Available models can be rewound with #31 wire, or,

if you're willing to go to about 250 to 275 ma drain in neutral, #30 wire can be

used to give a super power job.

Rewinding such a motor is not an extremely difficult job but it is time consuming.

For this reason, you may prefer another motor and gear train assembly. The most

quantitative description that can be given is that the torque of the output gear

should be of the order of 10 to 15 inch-oz and the speed of the output gear when

running free should be at least one revolution per second.

The above requirements apply to an airplane weighing in around 6 lbs. A heavier

airplane such as Bob Kirkpatrick's full-up Astra Hog will require about 30% more

output torque at the same speed.

The trend in dual proportional recently has been to use 2.5 volts from 2 Nicad

batteries. The Mighty Midget motor which became quite popular with 3 volts from

Silvercells is just not quite soupy enough to give both outside loops and smooth

flight at this lower voltage. We have used 3 Nicads per leg with this motor to give

a servo that will really throw a 6 1/2 lb airplane about. But a word of caution

must be given about this setup in that you must provide adequate spark suppression

to prevent relay welding. See October 1959 Everything Under Control for one workable

scheme.

Well, that was no small discussion of proportional servos and we'd better hurry

back to the subject at hand. This got started because we were trying to decide whether

we wanted 2 or 3 servos in a CAR ship. Now that we know how to get a good servo,

the question is really one of which is more convenient. If the battery supply will

tolerate the extra drain of a third motor, this is certainly a simple way to do

it. Most Nicads will tolerate reasonably heavy drains and a number of fliers have

used three motors and resulting continuous current drains of up to 600 or 700 ma.

With the normal complement of 0.8 to 1 ampere hour cells, this of course limits

the plane to about one hour of safe flying between charges and some fellows have

found it necessary to carry a portable charger to the field in order to "refuel"

their batteries. To obtain longer flight times, you must install heavier batteries.

This in turn requires more powerful servos, which in turn require more drain, which

in turn requires heavier batteries-which can go on endlessly if you don't stop at

some point.

To run three servos, you simply hook the aileron motor in parallel with the rudder

motor. This doubles the current being handled by the rudder relay, so again, a good

arc suppressor across the motors is a wise idea.

From a weight-flight time viewpoint, the mechanical coupling of the rudder and

ailerons to a single servo is a more logical approach than three motors. This of

course presents some real nightmares in linkage systems. Before we discuss the details

of possible linkage systems, we must consider the question of how much aileron action

we want and how much rudder we want. Another way of saying this is, "Do we want

the airplane to be controlled primarily in roll by the ailerons or primarily in

yaw by rudder?" The answer is that we want the ailerons to be the major control

action, the rudder a secondary effect to overcome some of the disturbing effects

the ailerons produce. This disturbing effect is called adverse yaw, the tendency

for the drag of ailerons to yaw the airplane in a direction opposite to that in

which we move the stick. So what we aim for is plenty of aileron effect to give

a rapid roll rate and just a hair more rudder than is needed to counteract adverse

yaw.

The actual areas and deflections of the surfaces of course will depend somewhat

on the airplane design, but there are some basic criteria to be followed. One can

get a rapid roll rate by using either small surfaces with large deflections or vice

versa. The vice versa is to be preferred. This will provide smoother response of

the plane because the large surfaces will operate in smooth airflow at all speeds

as opposed to possible turbulence that can occur behind highly deflected small surfaces.

A bit of turbulence behind an aileron at high speed can really foul up a nicely

balanced rudder - adverse yaw that was established at low speed - with the result

that a high speed axial roll will not be possible. With reed airplanes the small

deflection setup may not be preferred because it will require extremely "slop-free"

linkages to maintain neutral trim. However, a bit of slop in a proportional linkage

doesn't do any harm, so the small deflection setup is generally preferred.

Ailerons about 3 1/2" in chord by 15" in span have been found to work well on

the usual multi sized airplanes 6' in span by 12" chord. This is just slightly larger

than average full scale practice. These were deflected 10 degrees up and 5 degrees

down and with 5 1/2 lb. airplane produced 3 consecutive rolls in about 6 seconds.

Ailerons as small as 1 1/2" x 12" have been used with about 30 degree deflections

and while the planes were quite responsive in roll rate and easy to fly inverted,

the rolls were often not truly axial. There are of course a number of factors other

than the high deflections which could have contributed to this, not the least of

which was the fact that they were strange airplanes to the pilot.

In general, the amount of rudder deflection required falls somewhere between

1/8 and 1/2 of that required if the airplane were to be flown without ailerons.

This does not seem critical, and in fact, Buggy-Bug was flown with rudder ranging

from 1/ normal to zero without noting much difference in the performance. From this

experience I would naturally recommend a conservative rudder throw for a start because

too much roll action can produce crashes due to pilot errors.

Now that we know we want much more aileron effect than rudder, we can discuss

some of the critical points in linkages. For the mechanically coupled system, we

must decide whether the servo will be mounted in the wing and linked to the rudder,

or whether the servo will be mounted in the fuselage and linked to the ailerons.

Whichever method you decide upon, you should take precautions to in-sure that the

wing will not shift due to vibration and cause gross misalignment.

In view of the fact that the ailerons are to be the major roll control, and the

rudder is only secondary, it would seem best to put the servo in the wing with a

fixed linkage to the ailerons. In this way, a small shift in the wing may cause

the rudder to go out of alignment. This will usually foul up that particular flight

so far as getting real points in a contest. But it isn't likely to result in a crash.

On the other hand, if the servo is in the fuselage and the wing shifts the ailerons

you're headed for serious trouble! Some configurations such as high wingers do not

lend themselves readily to mounting the servo in the wing and it may have to be

put in the fuselage. In this case, be sure to put some sort of keying on the wing

to prevent it from shifting.

Shoulder wing and lo-wing jobs lend themselves readily to mounting the servo

in the wing. In fact the basic concept of the Pittsburgh Pointer was derived from

the fact that linkages and radio equipment fit conveniently into a shoulder winger.

The details of the aileron servo and linkage using balsa spools and nylon cables

are sketched. This setup involves no machined parts, is reasonably stiff and slop

free, and has worked without failure in over 300 flights. If you use nylon cables,

be sure to apply glue to the knots in the nylon and put some residual tension on

the cables so they stay tight in hot weather.

The cranks which drive the ailerons have their axis about 1/4" below the aileron

hinge line. This provides a two to one differential on the ailerons. That is, the

up aileron travels about twice as far as the down aileron. Differential is probably

a good thing to put on any airplane, CAR or other-wise, because it eliminates most

of the adverse yaw tendency. Without differential, the adverse yaw effects can vary

widely with speed with the result that the roll characteristics will vary with speed.

In the sketch you will note a crank which protrudes out of the trailing edge

of the wing. This fits into a yoke in the rudder rod to make the mechanical coupling.

The entire torque rod is covered with the turtle deck. The entire linkage system

of the Pointer, along with the position of the radio components, is shown in the

side view drawing. All linkages are indoors to prevent picking up stray blades of

grass and old propellers on takeoff. A detailed sketch of the elevator linkage is

also provided as well as a photo which is a view from the bottom side. I have used

this basic type of linkage for elevators for a number of years and found it to work

quite well. One feature which may not be immediately obvious is that the torque

rod turns 180° and thus is reduced to about 40° at the front loop on the

elevator. The reduction is done back at the elevator for the simple reason that

a given size of the torque rod then acts as though it were three to four times stiffer

than when the motion is reduced at the servo end.

The steerable tailwheel on the Pointer is supported by bearings in hardwood inserts

in the stabilizer and connects to the rudder linkage. No tail wheel brakes were

used since continual drag on the front wheels was found to be more effective for

proto ground work. It should be noted that the ailerons and elevators have counterweights

on them. These weights should be heavy enough to overbalance the painted surfaces.

They are the only reliable way to avoid flutter at high speed. Flutter will occasionally

tear off well-built ailerons and elevators, and if not this, it can cause the control

systems to be completely ineffective. This is not to be desired at the bottom of

a 200 foot power dive that started at 220 feet!

Since we expect this CAR system is going to let us do lots of inverted flying,

it is natural to debate whether a symmetrical airfoil should be used. The evidence

is clear that this is not necessary. We've seen CAR ships with Clark Y's, 2415's

and just plain french-curve airfoils that will stay on their back indefinitely and

which will do excellent axial rolls. It's also clear that the symmetrical foil is

also completely compatible with the CAR system. So I would say the choice of airfoils

depends entirely on criteria other than the fact that you want to use CAR.

The Pittsburgh Pointer uses a deBolt type symmetrical foil and the reason is

certainly not related to its being a CAR ship. This foil will "tuck under" in outside

loops with less elevator deflection than the usual 2415 type. This less deflection

allowed more than the normal gum bands on the elevator servo - which as we discussed

before gives a snappier servo response and resultant smoother handling. To go way

back to the airfoil to get one more gum band on the servo is real dedication to

the gum band pitch! But it does help.

The decalage and dihedral of a CAR ship can play an important role in its performance.

I use no down thrust in my airplanes. Using the thrust line as a reference, the

stab is then set at zero incidence and the wing at about plus 4° for symmetrical

sections and about plus 2° for lifting sections. This will usually give the

optimum upright and inverted stability. With these settings, the CG should be somewhere

between 30 to 35% of the wing chord. The principle behind a high effective incidence

angle is to force the tail and rudder to drag very low when inverted. This puts

a sort of groove in the inverted position and the airplane will almost fly by itself

in the groove. All the pilot needs to do is nudge it back when it starts to fall

off the fence.

I prefer a dihedral angle of about 3 to 4 degrees per panel (6° to 8°

total included angle). This is quite small and looks inherently dangerous along-side

a 16° Astro Hog, for example. This low angle is okay on proportional systems,

but it would probably be advisable to use a bit more if you intend to use reed equipment.

The higher dihedral will reduce the tendency to groove inverted, but it will be

a big help when flying upright, which after all, we do want to do occasionally.

I think the majority of the popular kits and designs that have been around for

the last few years would perform quite satisfactorily on CAR So just because you

may want to use this system you needn't feel it's necessary to start from scratch

and design an airplane. However, just because you have a kit and drawings is no

reason why you shouldn't take a bit of initiative and throw in some modifications

you think may improve the airplane. Be brave! A crash now and then is part of the

game.

With this radical statement, we will now get into the subject of how to fly with

CAR and we'll start out with a very conservative recommendation. Don't build a CAR

ship, or any aileron ship for that matter, until you've gotten a good bit of flying

under your belt. By the time you've built a ship with ailerons, you've invested

a good chunk of hard labor into a complicated gadget. It certainly shouldn't be

used to find out if your R.C. gear or linkage engineering is reliable.

Build a simple ship first, fly the pants off it until you know (1) how to fly,

and (2) that your equipment and installations are reliable. Occasional failures

of equipment and installations are unavoidable, but you ought to get your accident

rate down to less than one in 50 flights before going into a really complicated

rig. I think the statistics show pretty well that 80 to 90% of today's crashes are

due to installation failures, servos, linkages, wiring, etc., so put a bit of extra

care into this. With this word of caution, we'll talk about flying and specifically,

what are the peculiarities of the CAR system.

The first oddity you will note is in crosswind takeoffs. Good crosswind takeoffs

are nigh onto impossible. The reason for this appears to be as follows. When you

first pour on the coal for takeoff, the prop blast on the rudder gives you good

directional control. You can hold it crosswind so long as the airspeed is low and

your natural tendency will be to hold sufficient rudder to taxi straight out crosswind.

As soon as the plane picks up a bit of airspeed and gets light on its wheels, the

ailerons will start acting to roll the airplane, the wings will tilt and scrape

your elegant paint job on the tips. An unusually wide landing gear is some help

in this problem, but the complete solution is to take off straight upwind.

Proto taxiing can also be quite difficult. The trick here is to put lots of drag

on the main wheels. This keeps the ground speed low during taxiing, but it takes

a medium amount of power to pull the airplane on the ground. This medium power supplies

enough prop blast to the rudder to make it and the tailwheel quite effective while

the ailerons remain ineffective. In fact, it is mainly for this reason that the

rudder and tailwheel are on the Pointer. If it were not for all this "flying on

the ground" that we have to do at AMA contests, I would simply put in more differential

aileron and skip the movable rudder and tailwheel! I guess it's obvious I prefer

to fly my airplanes in the air!

You will also find crosswind landings and touch-and-goes to be difficult. In

a crosswind approach you will be feeding a bit of aileron. As soon as the wheels

hit the ground the airplane will try to shift directly into the wind. Like an ice

skater on the end of the whip, this puts new airspeed into the leeward aileron,

and the airplane will roll up onto one wheel and wing tip and drag itself to a stop.

Solution? Land into the wind.

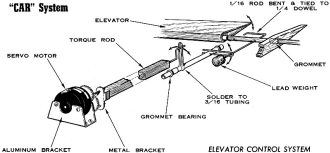

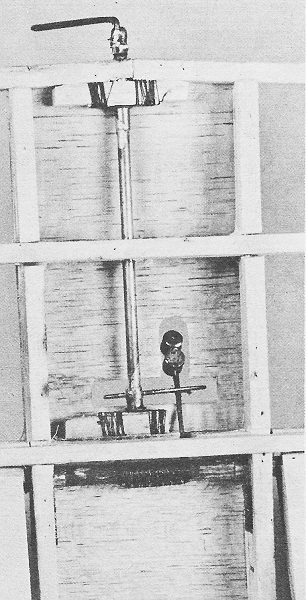

Elevator Control System

Elevator linkage, looking from the bottom. Portion of each movable

section seen at lower corners.

Many people who have the "spin-proof" Ercoupe in mind ask, "Will a CAR ship spin?"

In a full stall just before a spin, the ailerons are completely ineffective and

will not interfere with an attempt to spin. At Indiantown Gap this fall, Don Brown

and I were having a great time in a spin contest. His was a coupled-aileron hi-winger

of his own design. We tied at somewhere near 36 turns - so they will spin! The only

precaution you need to take is to be absolutely sure you've got a full stall before

yanking the stick to the corner.

Both inside and outside loops become a bit more difficult than they were without

ailerons. I speak specifically here of dual proportional air-planes where it is

possible to inadvertently apply a little rudder along with elevator. The constant

roll force from the ailerons can really make the loops go off heading. I also found

that if the relays are mounted in the airplane so that the armatures are horizontal,

G forces on the rudder aileron relay will cause the ailerons to go off center during

loops. It's best to mount the relays so that the armatures are vertical. To get

good loops, your system must be made free of all cross control. With practice, you'll

find the groove.

It begins to sound as though the CAR system adds troubles but gives little reward.

This is far from true. There are many new advantages at your command. The most obvious

of course will be your surprise to discover that inverted flying is pretty easy.

You can call inverted figure of eights and then fly them. Buzz the ground inverted

if you like, it's really not very dangerous. (Stay away from people!) It probably

won't be long before we find considerably more inverted maneuvers in our AMA contest

rules and coupled proportional ailerons are certainly a good way to get you ready

for this. With the ailerons the major control action, there is no problem flying

inverted. Right stick gives a right turn, left stick a left.

CAR ships are capable of doing top notch axial rolls. A true axial roll is supposed

to require cross control on the rudder and aileron combined with gentle elevator

control. However, this appears to be another anomaly between theory and practice.

The fact is, good coordination between ailerons and elevator is the most important

part of an axial roll. The dual proportional systems can provide the gentle amount

of elevator that is required. It takes a bit of practice to find this elevator coordination,

but it won't be long before you've got that airplane rolling as though it were fastened

to a guide wire.

All of the roll maneuvers such as the Immelmann, Cuban eight, and split S can

be done very clearly with CAR At first glance, the wing over sounds like an impossible

maneuver, but by gentle elevator play, you will find this quite easy. Victory rolls,

starting from either inverted or upright flight at 20 feet are also great sport.

This is a spectacular stunt-so long as you point the nose up about 30 degrees before

starting the roll, it's a perfectly safe one. After you've done a few of these you'll

give in to your urge to forget to lift the nose and just let her roll at 20 feet.

There is one important thing you should check before you bring the airplane close

to the ground while inverted. Will the nose lift up from a steep inverted dive?

There is a perfectly sound aerodynamic reason for the fact that if you build up

a lot of speed in an inverted dive the nose doesn't lift up easily when you push

full down. You should first try these inverted dives at an altitude that will let

you pull up on the stick in the event it doesn't respond to full down. There is

a natural tendency to pull full up whenever something goes wrong, but brother, if

you've gotten down to below 100 feet in an inverted dive, you've committed yourself!

You'd better have enough down elevator to lift that nose! Incidentally, if you contemplate

any accidental inverted landings, it's a good idea to make provision for the wing

to knock off rearward as well as forward.

Pylon racing is one of the most potent applications of the CAR system. The high

roll rate of the ailerons really lets you wrap the airplane around the pylon. The

ailerons are used only to roll the ship up vertically and you go around the pylon

with elevator. The CAR system which permits aileron control without the weight of

a third servo is a decided advantage in an event which has rapidly become a very

exciting scientific challenge.

The question has been asked whether coupled ailerons could be used on a single

channel rudder-only airplane. We tried this on the Pittsburgh Pointer one day by

the simple experiment of gluing a balsa wood slot across the control box to prohibit

elevator motion. (It's virtually impossible for a hardened duel flier to mentally

restrict himself from using the elevator.) I got the plane up there, did several

spiral dives. and a couple of pretty decent rolls before I panicked and crashed

through the balsa barrier on the box. There's no doubt I would have crashed the

plane if I hadn't resorted to the elevators, but this was mostly due to the fact

that I have the elevator habit. A hardened rudder-only flier could probably have

a real ball with ailerons.

I have also tried to fly the Pointer in slam-bang fashion to simulate multi reed

type operation. In other words, I mentally tried to compel myself to use full stick

whenever I felt the need to use any control. This worked alright for awhile and

I can report honestly that I finally made it through one short flight. But again,

I usually resorted to the proportional when I really got into trouble. However,

I was satisfied that a good reed pilot could fly the coupled system to advantage.

Though the coupled aileron system is relatively new to the R/C field, there has

now been enough experience in the system to prove its real potential. I expect that

through it, dual proportional and 5 channel reed airplanes will still be around

and be competitive for a number of years. The wiggle in proportional surfaces which

the uninitiated usually find aesthetically displeasing may go away. Not because

it disturbs the flying of an airplane, but mostly because we will be able to build

more powerful servos without it. But in reality, there is no real hurry to get away

from the wiggle for with a bit of effort you can get pulse servos which will let

you throw the airplane about with sufficient violence to bring out the daredevil

in you.

Much has been said about triple proportional systems - that they are on the way

and will be the ultimate. This is probably true. However, cheap and reliable triple

systems are still some-way off, and there will be new problems associated with this

system, not the least of which will be a real difficulty in learning to coordinate

the rudder and ailerons. The triple system would permit us to cross control the

ailerons and rudder, and some hot pilots might actually do knife edge flight instead

of the farce we called knife edge flight in 1959. But it is not particularly obvious

to me that those few occasions which require cross control are sufficient to justify

the new complication of having to fly 99.9% of the time concentrating on rudder-aileron

coordination. In this area, there is a real advantage with the coupled system in

that you don't have to clutter up your mind about coordination or which surface

to use for any particular stunt. You just take hold of the stick and fly it.

Posted December 25, 2021

|