|

This "Midget Radio-Controlled Auto" article from a 1952 issue of Radio &

Television News magazine was a major feat of engineering by Mr. William

Minor. He designed and built the car for his 6-year-old son. The amount of

electronics and mechanics he crammed into such a small volume in that R/C car

would have qualified him for an engineering position at a Japanese SLR (single

lens reflex) camera company. Although not explicitly mentioned, operating

the car by radio control back in those days required an amateur radio operator

license. Interestingly, he mentions that when choosing a frequency, he opted for

one above the television broadcast channels so as to avoid interference with

nearby TV sets. I've mentioned before how turning on my 27.195 MHz R/C system I

had as a kid in the early 1970's would cause the neighborhood women to scream at

me for messing up their daytime soap operas (during summer vacation days, since

I'd have been in school during the afternoon otherwise). Even though nobody

would deign to undertake such an extensive project nowadays, I thought the

extreme effort by Mr. Minor was worth honoring with a posting of his article.

Midget Radio-Controlled Auto

By William H. Minor By William H. Minor

The midget car and its control transmitter. The "on-off" switch can be seen at

the base of the right door. A license is required to operate this equipment.

Complete construction details on a control unit which will operate various types

of small models or children's toys.

If, like the author, you have a boy age 6, building a radio-controlled model

automobile for him is an interesting project.

Most radio-controlled models are, at best, difficult to build and often complicated

to operate or keep in working order. The model illustrated above affords excellent

control, yet it is simple enough for a child to operate after a few moments' instruction.

It is not difficult to build and can be made using readily available parts and ordinary

hand tools.

Three commands can be given the car: "move forward," "stop," and "move backward."

By a judicious choice of the original model car, the problem of turning was met

by the fact that the car will travel forward in a straight line but backward in

a circle. Thus, the car can be maneuvered like a larger car using only these simple

commands.

An attractive feature of the car is its physical size. The model is ten inches

long and stands three inches at its highest point. There can be no doubt, on examining

the photographs, that all available space is fully utilized for the control components.

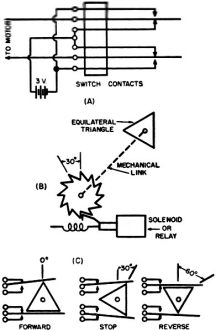

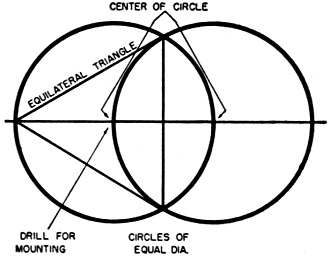

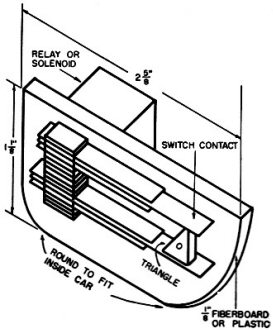

Fig. 1 - Construction details on the "decoder." A double-pole.

double-throw switch is activated by a triangular piece of plastic rotated between

the switch arms.

The transmitter described operates with A2 emission. This is defined in the regulations

as tone-modulated telegraphy A2 emission is permitted on the following frequency

bands.

Coil specifications are given for 144-148 and 220-225 mc., but the higher band

is recommended for two very good reasons. Of course, holders of currently valid

Amateur Operators Licenses will immediately recognize which bands they can and cannot

use.

Since 220 mc. is above the highest v.h.f. television channel, this is recommended

to eliminate possible interference with other services.

The second reason deals with the aspect of licensing. Operation of transmitting

equipment is limited to those who are licensed by the government. New regulations

recognize the value of experimentation by those who are interested in radio for

just such purposes as described. For this reason the Technician Class License is

available to anyone who demonstrates an interest and a small knowledge of technical

radio. The examination is quite simple and well worth the effort. This license permits

the use of all frequencies above 220 mc. which are set aside for amateur uses.

Invariably two other points in question arise. The first is that of "limited

radiation." Under the law, no license would be required if the transmitter output

were sufficiently low. Actually, the radiation could not exceed 50 microvolts per

meter at a distance of λ/2π from the transmitter. While it might be possible

to construct a transmitter which would not exceed the legal radiation limit yet

would operate the car over a very short range, it probably would require far better

test equipment to insure legal operation than is ordinarily available to the experimenter.

Operation, then, without a license is most certainly ill advised.

The second point concerns the often discussed Citizens Band at 460 mc. The advantage

would be in the ease with which an operator's permit can be obtained. The catch

is that the FCC has some rather rigid specifications on the transmitting equipment

that can be used. It would be extremely difficult for the average constructor to

design, build, and secure approval for the necessary transmitter. This rules out

the use of the Citizens Band, for this project at least.

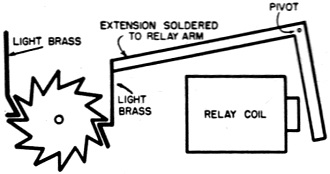

Fig. 2 - Details of reversing switch relay.

Fig. 3 - How an equilateral triangle is obtained using a compass

and a straightedge.

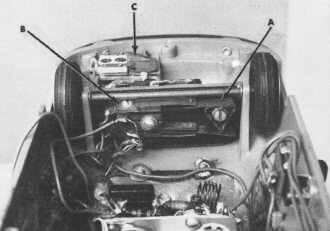

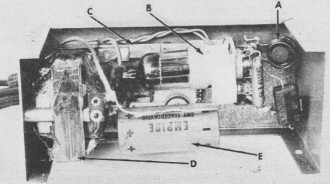

View of model car looking toward rear axle and showing the locations

of (A) the equilateral triangle. (B) the decoder switch. and (C) the decoder relay

unit.

The model car and its transmitter shown beside pack of cigarettes

to indicate size.

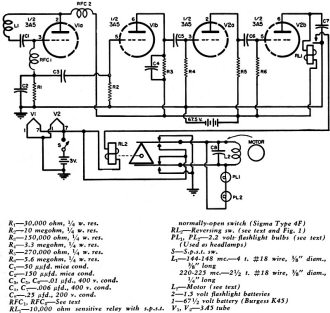

Fig. 4. Complete schematic of the receiver which is installed

in the model car.

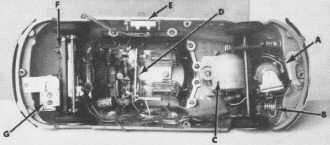

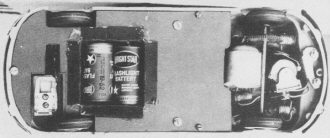

Bottom view of car with base plate removed. Components visible

include: (A) sensitive relay, (B) head lamp, (C) drive motor, (D) receiver, (E)

"on-off" switch, (F) decoder mechanism, and (G) the decoder relay. See text for

complete details.

Bottom view of the model automobile with the base plate in its

correct position.

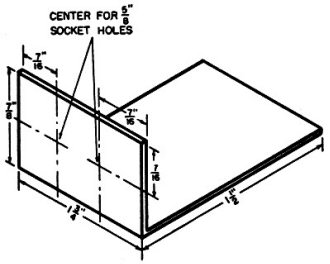

Fig. 5 - Decoder switch mounting procedure.

Fig. 6 - Receiver chassis dimensional data. The chassis measures

1 1/2 inches by 1 3/4 inches and has a 7/8-inch flange. It may be constructed of

any lightweight metal.

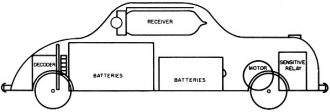

Fig. 7 - Outline drawing of the car showing how the various components

are placed.

A little investigation will prove that the Technicians Class License can be obtained

after only a short period of study. For this reason it is rapidly becoming a very

popular license.

The Car

The builder might wish to start from scratch and assemble the entire model to

his own specifications, but modification of an existing toy is no less interesting

and time is saved in the over-all process.

There are, on the toy market, several small automobiles that are of the "wired-control"

type, that is, they contain a small 3-volt electric motor and a pair of wires that

lead to a battery case designed to be held in the operator's hand. Some of these

cars have pneumatic steering control, some have no control at all. This particular

model was chosen for two distinct reasons. Although it was small, it was not so

tiny that it was necessary to revert to subminiaturization. The unique method of

steering fits into the plans for keeping the controls simple.

This car has the drive motor installed on the front wheel mount and is free to

turn left and right with the wheels. The rear wheels are not in line with the axis

of the car. As the car is driven forward the torque of the motor is canceled by

the offset back wheels. As the car is driven backward the offset causes the car

to turn.1

The Decoder

The heart of the car was, in its "wired-model" form, a reversing switch which

was located in a battery case held in the hand. For radio control, this switch had

to be located in the car and some arrangement made for it to assume the position

desired by the operator. The mechanism which performs this task is called the "decoder."

There are several methods of accomplishing decoding. The one to be described is

about the simplest possible.

Examine Fig. 1. This shows the construction of a double-pole, double-throw switch

activated by a triangle which rotates between the moving arms of the switch.

Using relay contacts, a set is constructed exactly as shown in the drawing of

Fig. 1. No dimensions are given, as the builder may have to construct it from whatever

parts are available. For simplicity, the constructor may desire to buy a kit of

relay contacts as those manufactured by Guardian. These kits are reasonably priced

and simple to assemble in any manner desired. A kit contains sufficient parts for

two switches. In the event Series E-200 contacts are used, be careful in the over-all

construction of the decoder, for the space in the car is limited and these contacts

are a snug fit in the "trunk compartment" over the rear axle. See the photograph

below showing location of components.

After the switch has been constructed, measure the distance between two moving

arms. Measure the distance one of the moving arms must travel to make contact with

the outer stationary arm. Now add the distance the arm must travel to one-half the

distance between the moving arms. Draw a circle on a piece of stiff non-conducting

material using this figure as the radius of the circle. Inscribe within the circle

an equilateral triangle and after marking the center, cut out the triangle. The

material from which this triangle is made may be a piece of plastic about 1/8 inch

thick. Fig. 3 shows how an equilateral triangle may be inscribed in a circle using

a compass and a straightedge.

This equilateral triangle may t used only if the proper ratchet gear is in combination

with it. The ratchet must have twelve teeth so the triangle will turn through 30

degrees each time the solenoid is activated.

This twelve-tooth ratchet gear was taken from a broken alarm clock Spring-variety

clocks contain two of these gears, one on the main spring and another on the alarm

spring. It is wise to inspect the gears before tearing up the wife's favorite kitchen

clock, for some may not have the proper number of teeth. (The gear, that is; it

is assumed the wife has the correct number.) Larger clocks have gears with a shaft

about 3/16 inch in diameter. This shaft can be cut off to just the correct length

to pass through a small mounting panel then drilled and tapped for a No. 4 or 5

screw. The triangle can be bolted to the shaft on the side of the panel opposite

the ratchet.

The diagram Fig. 2 shows the gear being activated by a reconstructed relay which

is available on the junk counters of many of the surplus stores. It originally had

a 300-ohm winding for use in 28-volt d.c. systems. The winding was removed and replaced

with enough #28 wire (approximately 92.46 feet) to have a resistance of 6 ohms.

An easy method of winding this is to clamp the core form in the chuck of a hand

drill and turn the drill as the wire is fed evenly in by hand. Six ohms of #28 wire

just fills the spool of this particular relay core.

After winding the new coil, replace the core and set the relay for a stroke that

pulls easily yet firmly. Add an extension to the relay arm so that the tip will

move through a distance equal to or very slightly greater than the distance between

teeth on the twelve-tooth ratchet. Fig. 2 is a drawing of the physical additions

that were made to the relay to operate the reversing switch shown in the photographs.

Although only one switch was needed, two of them were constructed and are offered

as alternate designs. The second switch, the same size physically as the one just

described, was activated by a solenoid. The mechanical connection is shown in Fig.

1B.

Using a small piece of aluminum tubing through which a soft iron nail will slide

easily, wind 6 to 8 ohms of #28 wire (approximately 93 to 123.2 feet) in a coil

about one inch long. Insulate the winding by wrapping on a thin layer of tape. Cut

a strip of metal from a tin can - the width equal to the length of the coil. Wrap

the coil in the metal and solder it. Build the ends of the same metal, allowing

the aluminum tubing to protrude a little. Make a plunger of the soft iron nail with

a catch on it as pictured in Fig. 1. An iron screw should be run into the opposite

end of the solenoid to provide a stop for the plunger and to afford a greater attraction

for it during the time a current is in the coil. This solenoid is mounted on the

switch panel in such a way that one stroke of the plunger will cause the switch

ratchet to move through 30 degrees or one tooth.

Fig. 1C shows three consecutive positions of the triangle and switch arms as

the relay or solenoid is activated. Follow the electrical. wiring as shown in Fig.

1A. This is not the only arrangement which would result in a reversal of current

through the motor, but is the method which will insure that the battery will not

be shorted during the movement of the ratchet and triangle or in the "off" positions.

The only time current is drawn by the decoder is during the actual pulsing of

the relay. This time can and should be made very short by transmitting only short

pulses. This eases the strain on the batteries within the car.

The Receiver

In order that the car will operate with a minimum of adjustments at the receiver,

a circuit which is sensitive yet stable is highly desirable. A one-tube receiver

could be constructed that would occupy less space than the one shown, but this type

of receiver re-quires adjustments quite frequently. The circuit of Fig. 4 is not

at all "fussy" as to adjustments or deterioration of "B" batteries. In fact, after

this particular receiver was constructed no adjustments were required before actual

installation in the car. It worked properly the first time it was turned on.

A superregenerative detector is followed by two stages of audio amplification.

The last stage has a grid resistor returned to "B+" allowing the tube to draw sufficient

current to operate the sensitive relay in its plate circuit.

When an audio signal is supplied to the grid of this tube, the rectifying action

at the grid supplies a bias across the grid resistor that will serve to cut the

tube off. The consequent decrease in plate current opens the sensitive relay. This

receiver requires that the transmitter with which it is used be modulated.

The sensitive relay was adjusted to close at 1.8 milliamperes and open at 1.1

milliamperes. Several types are available but the Sigma 4F has been suggested since

it may be adjusted over a range of operating conditions. To make tests with these

relays, connect a milliammeter, the relay, 45-volt battery, and a 500,000 ohm variable

resistor in series. By slowly lowering the resistor value a point can be found where

the relay just closes. Note this as the "closing current." With the relay closed

increase the resistance to the point where the relay opens. Note this current as

the "opening current." The necessary adjustments should then be made in order to

set these points where desired. The relay should, however, not require more than

2 milliamperes to close, for the 3A5 tube with a 10,000 ohm relay load and 67 1/2

volt supply will not draw more than 2.1 milliamperes. The hiss from the detector,

which serves to bias the last stage, will further cut this current.

In purchasing component parts for this receiver, buy the smallest available.

Condensers designed for use in three-way portable receivers are 1/8 inch in diameter

and 1/2 inch long. These fit very nicely in the allotted space. Although 1/4 watt

resistors were used in construction of this unit, the little 1/8 watt units would

make construction a little easier. Be sure to use mica or equivalent condensers.

in the r.f. circuit.

Base plate showing "B" battery and the box which holds two size

"C" dry cells.

Reverse of the base plate showing how dry cells are located for

easy replacement.

Space can be saved by making your own r.f. choke, about 35 or 40 turns of # 36

wire on the body of a 15 megohm, 14 watt resistor. A neat method of doing this is

to clamp the resistor by one of its pigtail leads in the chuck of a hand drill,

holding the drill in a vise. The wire can then be wound in the same way as was suggested

for the relay coil.

As soon as the receiver is complete, connect the batteries. Use a pair of headphones

in series with a 0.006 μfd. condenser and place this across the sensitive relay.

A hiss should be heard in the headphones. If no hiss is heard either the amplifiers

are not working or the detector is not superregenerating. Remove the headphones.

The sensitive relay should be closed with power turned on. Touch the finger of one

hand to the grid of the first amplifier stage and put the other hand on or near

the 117 volt wire of the soldering iron. The relay should open and a 60-cycle buzzing

noise should be heard.

If this buzzing is not heard, the amplifiers are not working. Recheck the circuit.

Assuming that the amplifiers are OK and the hiss has been heard in the headphones

another trouble might be that the relay will not close. This could happen because

the audio fed into the amplifier by the detector does not allow sufficient current

to flow in the final stage. Two things can be done to correct this. There should

be sufficient shunt capacitance in the circuit to bypass the squelch frequency,

but if there is not, the condenser C4 across the plate load resistor

of the first stage of audio can be increased. Care should be taken not to increase

it so much that the audio from the received signal will not open the relay. Another

thing that may be done is to lower the voltage to the detector by placing a resistor

in series with the "B+." Be certain, if this is done, that the tube is still in

superregeneration as indicated by the hiss heard in the headphones.

When the set is operating properly the relay should close after the power is

turned on and remain closed until a signal is received from the transmitter. A received

signal should hold the relay open as long as it is being received.

This receiver, using the component values given in the parts list, should draw

a total of 4 milliamperes with no signal being received. This will decrease when

a signal is received.

Location of Components

Fig. 7 shows an idea of the correct location of the component parts of the control

system. There is no spare room. Care must be taken that the parts do not occupy

more space than has been allocated for them.

The receiver is mounted flush against the top of the car by a single 4-40 machine

screw. The decoder is mounted beneath the rear axle with the relay or solenoid extending

out into the trunk compartment. The sensitive relay is mounted in front of the axle

under the hood. Batteries are fastened to the base plate which screws to the under

side of the plastic car. Removal of this base plate exposes all operating parts

of the car.

Another feature is not at first apparent. The headlamps are the pre-focused 2.2

volt bulbs ordinarily found in the pen-cell flashlights. These are just the proper

size to poke through the metal grommets the original car used as headlamps. Two

of these bulbs are connected in series (using soldered connections) and are glued

into the holes. For more realism, "tilt" lamps may be made. Place the bulbs in a

flashlight and note whether the rays come directly along the axis of the flashlight.

If they do not, while the bulb is lighted lightly strike the flashlight against

some solid object. The filament should shift in the bulb causing the beam to tilt

downward. Mark the side of the bulb toward which the beam bends and when it is glued

in the car place this mark down. Then when the car runs the lamps will cast two

round beams of light like the headlights of a real car.

Receiver Power Supply

The space within the car is quite limited and special care must be taken to provide

the necessary power for operation without exceeding the allocated volume.

The batteries required are one Burgess K45 and two size "C," 1 1/2 volt flashlight

cells. The K45 is a 67 1/2 volt battery chosen because of its compact physical size.

This battery is slightly smaller than its Eveready equivalent which was a trifle

too large to mount in the available space.

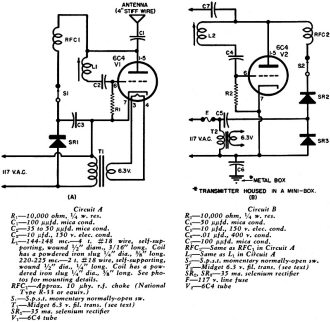

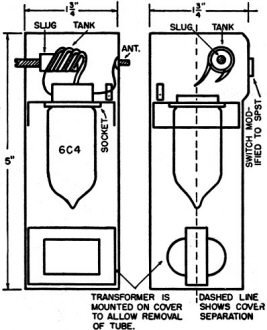

Fig. 8 - (A) Original version of the transmitter using an ultraudion

oscillator. (B) Improved version which performs better but requires an additional

rectifier. The photos of the transmitter appearing in this article are of the "improved"

circuit (B).

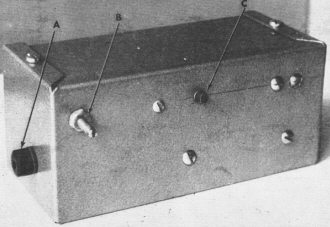

The transmitter as housed in a Bud "Mini-box." (A) Phone tip

jack for the antenna. (B) the transmitter tuning screw, and (C) the transmitter

control button.

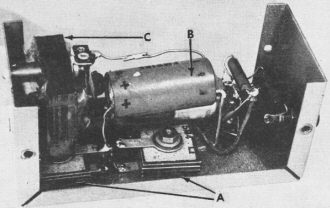

Side view of transmitter with dust cover removed to show: (A)

the selenium rectifiers, (B) the clamper condenser, and (C) the midget filament

transformer.

Top view of transmitter with dust cover removed. (A) Coil and

slug, (B) oscillator tube, (C) the switch, (D) the midget transformer, and (E) the

clamper condenser.

Fig. 9. Top and bottom chassis views showing how the transmitter

parts (Fig. 8A) are mounted in the original battery case.

Originally the car was operated by 3 volts obtained from a series-parallel arrangement

of ten pen cells. It was found, however, that the middle size flashlight cell worked

equally well, was more economical, and was far easier to change.

The base plate of the car was replaced by a piece of thin composition, cut as

shown in the photographs. The original metal dust cover was used as a template.

Note that an additional opening was provided for the relay and its arm which protrudes

slightly below the level of the axle.

A small box, the correct size to hold the two 1 1/2 volt batteries, was made

from light cardboard and bound with Scotch electrical tape for greater rigidity.

This was inserted through a square hole in the base plate and then glued in place.

A metal plate was fastened along the inside of one side of the box to contact the

battery poles and connect them in series. On the opposite side of the box roundhead

screws provide contacts for positive and negative poles of the two batteries. The

batteries slip in and out, but are secure enough to stay in place even with the

rather rough treatment a small boy gives his play things.

The "B" battery is held firmly in place by a thin aluminum band anchored at the

ends by 6-32 screws and nuts.

The Transmitter

The choice of transmitter circuits depends upon the preference of the builder,

the frequency at which he desires to operate, and whether it is to be a.c. or d.c.

powered. No great amount of power output is demanded of the transmitter, but it

is important that the output be modulated.

Two transmitters are described because both were built and found satisfactory.

The first of these is pictured in Fig. 8A. A 6C4 tube is used in an ultraudion oscillator

circuit having its plate voltage supplied by a half-wave rectifier not fully filtered.

The 60-cycle ripple appears in the transmitter output as modulation. The advantage

of this circuit is that it can be constructed in the plastic case which was originally

the battery case of the model car. Fig. 9 shows the location of the components in

the case.

The transmitter of Fig. 8B differs from the other only in the design of the power

supply for the plate. It does, however, represent an improvement that makes this

superior to the former unit. It has the disadvantage of being slightly larger and

requiring an additional rectifier.

The power supply will probably be recognized as one form of a voltage doubler

circuit minus the filter. The action of the condenser and rectifier arrangement

is to clamp the average voltage at the line voltage and allow the peak to vary from

zero to 220 volts at a 60-cycle rate. Since the plate voltage swings as it does,

the transmitter is 100% modulated at 60 cycles. The audio component of the transmitted

signal is clean and the maximum the carrier can supply without splatter and signal

distortion. This is important because it is the audio which operates the sensitive

relay in the receiver.

The filament voltage in either unit is supplied by a midget transformer with

a secondary winding that will give the necessary 6.3 volts. This should, if possible,

be one of the several midgets which have been designed for this purpose. One such

transformer is found in television boosters.

A universal output transformer will also serve the purpose without modification

after the voltages have been measured and the correct taps chosen.

The original choice of supplying the transmitter plate with voltage from the

a.c. lines was made for the simple reason that it eliminated the necessity for a

modulator being built into the set. A battery supply would necessitate an additional

tube and transformer as an audio signal generator and a modulator. The use of a.c.

is no serious disadvantage since the car is normally operated indoors where the

supply is readily available.

Running the Model

By this time the builder is probably quite anxious to get the first run-in on

the model. A little experience will show the best way to get the car started. The

description of a simple procedure will help.

When the switch in the auto is first turned on and before the tube filaments

have had time to light, the de-coding relay will operate. This is due to the fact

that the sensitive relay is not opened until the receiver current reaches the closing

current. Operation of the stepping relay will cause the drive motor to start running.

To avoid this, hold the thumb on the armature of the sensitive relay for about a

second while the tubes warm up to operating temperature.

Now place the car upside down on the floor and standing several feet away with

the transmitter plugged into the a.c., slowly turn the transmitter tuning slug until

the relay in the car operates each time the transmitter switch is depressed. Avoid

holding the "transmit" button down while the transmitter is tuned to the receiver

frequency, for this allows the stepping relay to be held closed. This is an unnecessary

drain on the batteries.

(Editor's Note: To make certain that you are operating within the frequency limits

of one of the amateur bands, check the transmitter frequency with a calibrated receiver,

wavemeter, or Lecher wire setup. Adjustment of receiver coil L, (Fig. 4) may be

necessary to establish the proper operating frequency.)

After the transmitter has been tuned, set the car on its wheels and you are ready

for the first run. Quickly push the transmitter button and release it immediately.

The relay in the car will operate and the car will move. Pulse the button again

and the car will stop. A third pulse will start the car moving in the opposite direction.

Play with it awhile and see how easily the car will obey your command.

Now that the car is made, will the kid you started to make it for get it? He

will! How soon?

1) Manufactured by the Vibro-Roll Products, Inc., Pittsburgh 22, Pa. This

particular model is their "Sedan" and is available in some of the larger toy departments.

Posted March 11, 2023

|