|

In

1957, experimentation with full-size vertical-takeoff was still

relatively new. The

Convair XFY Pogo is probably the most familiar of the attempts.

It sat on its tail and had two huge counter-rotating props in the

nose. Without lightning speed computers for stabilization, it required

the pilot to do most of the flying. Things just did not go well.

If was not until the Harrier Jump Jet that practical VTOL aircraft

became a reality. Jet engines don't suffer anywhere near as much

negative effect of counter-torque. In fact, the low moment arm of

the high rotational speed of the compact turbine mass actually helped

stabilize the airframe. As with many aspects of model aviation in

the glory days, hobbyists were eager to try their hands at those

out-of-the-box (a term not even uttered yet) configurations. Here

is a simple one that worked well.

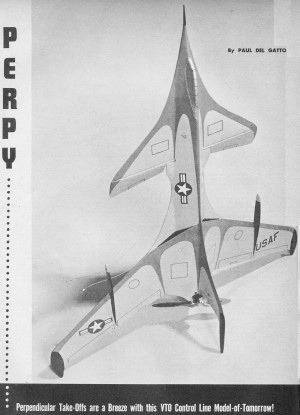

Perpy

Perpendicular Take-Offs are a Breeze with this VTO Control

Line Model-of-TomorrowBy Paul Del Gatio

This

was no "peaches and cream" project! We were not so fortunate as

to have our first endeavors meet with success; we ran into many

problems which had to be resolved before the model's performance

could be measured against that of conventional configurations of

similar size and structure. This

was no "peaches and cream" project! We were not so fortunate as

to have our first endeavors meet with success; we ran into many

problems which had to be resolved before the model's performance

could be measured against that of conventional configurations of

similar size and structure. When we first undertook this

project we expected to build it along lines similar to that of an

all-balsa sport free-flight model using a Half-A or small Class

A engine that would propel it into the air from a vertical take-off

position. It seemed to work pretty well on paper when we

compared power available to anticipated weight of the model, with

due consideration to rapid acceleration. Our initial trip

to the flying field was truly a disappointing one. First flight

was accomplished with a hand-launch. We observed several flaws.

It was evident from the start of the flight that the center

of gravity was too far back to permit proper handling and control

during flight. Then, too, it appeared that we had exceeded practical

limitations for line stagger. Lastly, Perpy did not have enough

power available to respond smoothly and effectively to the controls.

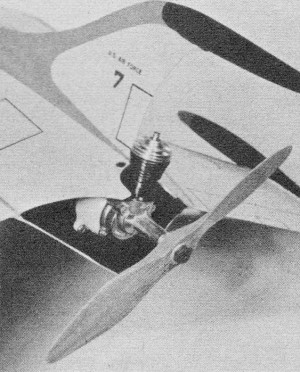

We decided to use a hand-carved, pusher-type propeller with

an .09 engine. The prop carved was 7 inches in diameter and of very

low pitch. This combination we felt would provide more rapid acceleration

from a vertical take-off position.

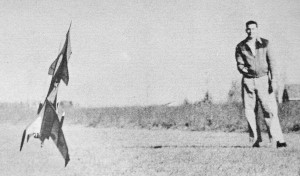

Up-'n'-away she goes! Vertical take-offs require a "hot" .075

or .09 power plant.

Half-A (.049 cu. in.) engines okay for hand· launch flying with

light models.

(There was no doubt that the hand-carved prop was superior to a

"store-boughten" prop for this particular purpose; however, it was

not a sufficient enough change to make a pronounced effect on the

model's performance and handling characteristics.) We ventured

out once again to see what we could do. From the moment the "09"

roared to life we sensed that everything was as it should be. When

Perpy zoomed skyward upon release right to the top of the line we

were more happy. The model was no longer sluggish; she responded

rapidly and smoothly to the controls. Ballast that we had added

forward enabled us to maintain normal trim in level flight. It was

a real pleasure to see how well she handled even after the engine

cut and speed gradually decreased prior to rolling in for the landing.

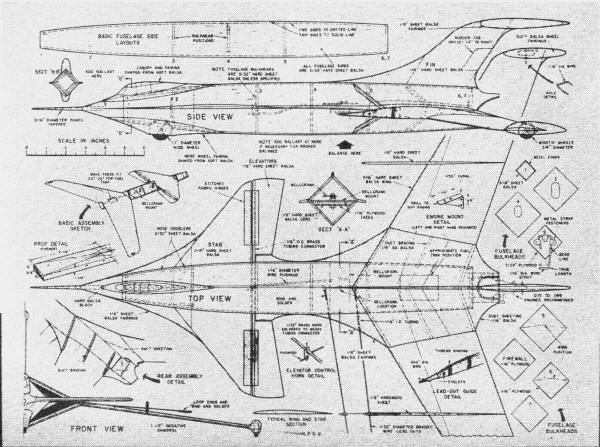

Construction: Despite its streamlined appearance,

this model is easy to build and requires only a few full evenings

to complete. For those who are new to modeling some details may

prove laborious, but a little extra effort should resolve the situation

very nicely. It's best to begin construction with wing and tail

surfaces, since much of the fuselage will be assembled around them

to insure correct alignment and speedier assembly. Both

wing and tail are shaped from 3/16" hard sheet balsa and sanded

to desired cross section. Once wing halves have been completed bevel

center edges where they join to form flush fit when negative dihedral

is added. Reinforce joint with fabric and coat liberally with cement.

Tail surfaces are similarly shaped. To assemble, cement elevators

to brass connector on which has been soldered control horn, join

this unit to stab with stitched fabric hinges. Begin fuselage

assembly by cutting out all bulkheads and sides. Bend nose gear

strut to shape, fasten to #2 plywood bulkhead. Join the

two sides which form fuselage bottom beginning with central bulk-heads

and working forward and back. When fuselage bottom has been assembled,

cement wing and tail surfaces in position. Make cutout for fuel

tank in wing center section (should you be using a separately mounted

tank). Keep opening small to provide tight fit. Install

bellcrank assembly complete with wire lead-outs. Bend wire pushrod

to shape and joggle ends to simplify installation. Cut and bend

engine mounts. Slight variations may be needed for different engines.

Bolt engine mounts to firewall; use lock washers to eliminate vibration.

Proceed

to assembly of main fuselage. Once the basic fuselage assembly has

been completed, rough-shape and cement in place nose block, canopy

and nose wheel fairing. Strength and appearance are enhanced

by addition of duct assembly. First add 1/8" square balsa bracing,

then cement duct sheeting on top and bottom. Add other remaining

details such as the fin assembly and fairings, wingtip wheel assembly

and fairings, and lead-out guide assembly. When basic structure

has been completed fill all cracks, nicks and joining surfaces;

permit thorough drying; then smooth entire assembly with fine sandpaper.

To apply suitable finish begin with two coats of wood filler.

Next apply two coats of fuel proof clear dope. The colors we chose

were yellow-orange with deep red surface trim; details in black

and silver. Since we sought light weight we used only three coats

of the basic color (yellow-orange) over the entire model; on top

we added all our trim. Then a gentle rub-down for added lustre.

Details such as hatches and control surface outlines can be done

with ruling pen and India ink. Flight and adjustment instructions

appear on the full size plans.

Perpy Plans

<click for larger

version>

Full size drawings for Perpy are on Group Plan #357 from Hobby

Helpers, 770 Hunts Point Ave., New York 59, N.Y. (50c)

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted March 18, 2012

|