|

A lot of careful thought and detail

went into planning and rationalizing why a biplane version of the venerable MO-1

control line Carrier model should fly better than the traditional monoplane platform.

It was January of 1973 when this article appeared in American Aircraft

Modeler magazine. Time has shown that the old adage about if something isn't broken,

don't fix it must ring true here. That is not to say efforts should not be undertaken

to improve on a design, just that in this case going to a biplane configuration

was not the answer. Maybe website visitor Duke J., who wrote to ask for this article,

can pick up where Mr. Gerber and Mr. Higley (yes, THE Harry Higley) left off. Maybe

a MO-Tripe...? Mo-BipeRequirements for Profile Carrier allow non-scale

designs.

A biplane can offer several advantages such as reduced weight and frontal area. A biplane can offer several advantages such as reduced weight and frontal area.

Don Gerber and Harry Higley

During

the 1920s Martin made the MO-1 monoplane which was used as the subject for both

a Class I and Class II Navy Carrier ship. The Class I version appeared in the August

1969 issue of American Aircraft Modeler. The subject of this article was designed

for the Profile Navy Carrier event, and its name was not chosen because Martin made

a biplane variant of the MO-1 - they didn't. It was chosen because the Bipe retains

many of the construction features and the same general appearance of the MO-1.

In an era when the Scale Navy Carrier events were dominated by Guardians; the

MO-1 was a most unlikely but highly successful choice for the event. The real airplane

was to be a battleship based observation plane in the early 1920s. Only two ever

saw Carrier service; an old letter reveals they were not regarded as fit for this

service by the Navy. The MO-Bipe may appear an unlikely choice for Profile Carrier,

but for a different reason. Most fliers do not normally think of a biplane for a

Speed event.

Due to the nature of the rules, the biplane configuration, however unlikely it

may seem, offers the very decided advantage of reduced weight and frontal area.

A monoplane with a 36-in. span would require about an 8.5 in. chord to achieve the

300 sq. in. required by the rules. A few airfoil sketches will show that the minimum

thickness that will maintain the structural integrity of a built-up wing is about

0.75 in. This gives a frontal area of about 27 sq. in. A wing this large does not

lend itself well to solid construction. The MO-Bipe used two solid, easy to

shape wings with a 28 in. span, 5.7 in. chord and 0.25 in. thickness. These give

a total frontal area of 14 + sq. in., or only slightly more than half that of the

monoplane. The Bipe will also have a shorter fuselage because of the reduced wing

chord. This 15 to 25 percent overall reduction in fuselage dimensions will provide

a substantial weight reduction. One last advantage for the biplane is the capability

of using full span strip ailerons on the lower wing which eliminates the need for

tip weight, thus saving another ounce. Strip ailerons are easier to install than

conventionally placed ailerons, as there is no need for long torque rods or clumsy

pushrods. The importance of the working ailerons and rudder cannot be over-emphasized.

This plane was designed from the ground up for Profile Carrier, but the full potential

of the design cannot be realized unless the moveable ailerons and rudder are used.

Unusual construction features shared by the MO-1 and MO-Bipe include solid wings

and easy to install semi-enclosed controls. Another common feature is variable sweep

line leadouts. The less the lines sweep back, the faster the plane will go. However,

the plane will be more likely to come in. By trying different holes in the tip guide,

the most favorable line sweep may be found.

Full credit for the design belongs to Don Gerber. Don and I correspond regularly

and this spring he sent some photos of the MO-Bipe and asked if I would be interested

in a joint article, as he did not want to devote the large block of time that assembling

an article such as this requires.

All painting was done with linkages removed.

This is also handy when crashes make major adjustments necessary.

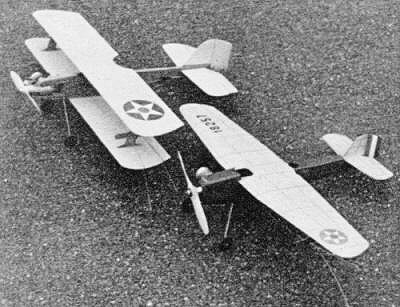

The MO-Bipe with its predecessor the MO-1, both in pre-WWII markings. Only the

MO-1 has scale heritage.

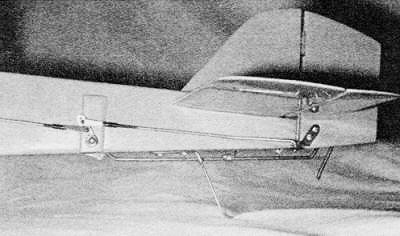

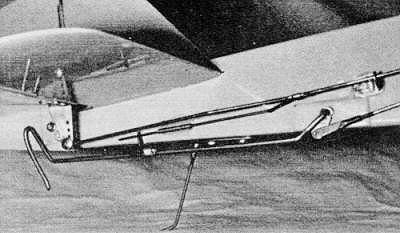

Adjustable leadouts provide for windy or calm conditions. Moved forward line

tension is less but speed is higher.

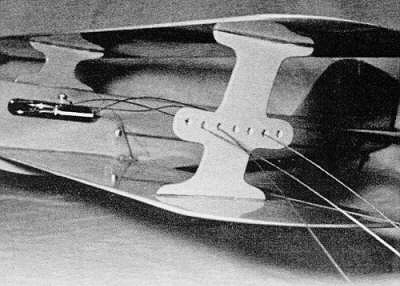

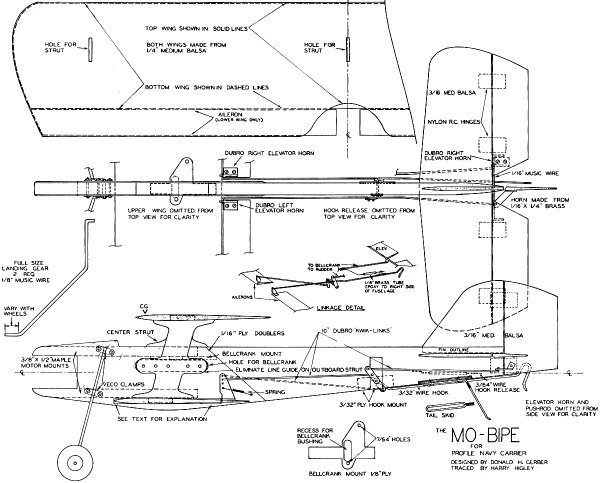

Plans show the hook-drop, elevator and aileron systems graphically. Note use

of adjustable clevises throughout.

Construction

The construction procedure was planned to avoid two problems. First, a completely

assembled biplane is difficult to finish due to the limited space between the two

wings. Second, painting after the controls are installed at best will look bad because

of partially painted rods and other components; worse yet, the paint may foul the

whole system. The strategy employed is to assemble the plane minus the upper wing

and struts. The controls are then temporarily installed, checked, adjusted and then

removed prior to finishing. The main frame, control surfaces, struts and upper wing

are finished separately, and then the whole model is permanently assembled.

To begin with, cut all plywood parts. These include the bellcrank, hook and tail

skid mounts, the struts and the plywood fuselage doublers. The doublers should be

cut a little oversize as they may not end up in exactly the position they should.

The resulting slight overhang is easily trimmed and sanded flush with the fuselage.

Drill the required holes in the bellcrank mount, inboard strut, and tail skid mount.

Now is as good a time as any to bend the landing gear, tail skid and hook. Attach

the wheels with soldered washers. Attach the tail skid to its mount with No. 6 x

3/8" sheet metal screws. This will facilitate easy removal of the skid for painting

and replacement, though the latter will probably never be necessary.

The bellcrank on the J. Roberts unit must be shortened. Notice on this control

unit that there are, in addition to the holes provided for "the leadouts, two dents

indicating alternate leadout positions. Drill at these points, then trim the excess

from the bellcrank. Attach the leadout wires. I personally prefer Perfect brand

- they are a little stiff, but are strong and solder well. Mount the control unit

to the bellcrank mount to verify that the moveable bushing that is recessed into

the mount has adequate clearance. Once this is established, remove the control system.

The next operation is fabricating the fuselage. Cut the motor mounts to the correct

length. It will hurt nothing to drill 1/4" holes in them from the landing gear mount

back; it will save some weight. Glue the bellcrank mount to the upper motor mount.

Cut the fuselage from 1/2" sheet balsa. Choose this piece of wood carefully as a

heavy sheet adds nothing but weight. Cut all slots including the bellcrank hole,

except the one for the lower wing which will be cut after the doublers are installed.

Cut the recesses for the hook mounts and the tail skid mount, and glue these in

place. Glue the motor mounts in position. Notice on the plans that there is a piece

of 1/2" wood on the top of the upper mount. Cut this from a scrap and glue it in

place. The doublers may be attached with contact cement or Titebond. If the latter

is used, clamp between blocks, remove any excess glue with a wet rag, and allow

to dry overnight.

After the fuselage assembly dries, it is convenient to drill holes for the motor,

tank, hook and landing gear. If a drill press is used, it will be necessary to hold

the fuselage on the block of wood so that the bellcrank mount clears the table.

Trim the excess from the fuselage doublers and sand these even with fuselage.

Now the slot for the lower wing may be sawed. Hold the fuselage on a couple of

blocks so the bellcrank mount clears the jigsaw table. The slot should be 1/4" and

not the shape of the airfoil. The lower wing is left with a rectangular cross section

where it intersects the fuselage. There are two reasons for this. First, it is difficult

to cut a hole that will mate well with the airfoil. Second, sliding the fuselage

onto the wing would surely nick and gouge the wing if the slot was a snug fit. Attach

the landing gear.

The wings are made from 1/4 x 6" medium sheet balsa and are no more difficult

to shape than a wing for a hand launched glider. Draw parallel lines on the top

and bottom of each wing 1.75" from the leading edge and 2.5" from the trailing edge.

Also draw lines down the middle of the leading and trailing edge of the wing blank.

Sanding the airfoil should be done on a smooth surface. Any glue glob will chew

up the under-surface of the wing. This sanding is done with a 3 x 12" block with

60 grit paper glued on one side and 220 grit on the other.

The lines that are drawn on the wing blanks are used as guides to shape the airfoil.

As one looks down on the wing, the wood above a plane determined by the line on

the leading edge and the forward line on the top of the wing is removed by sanding.

The airfoil is shaped by removing these wedge-shaped sections. The center section

of the bottom wing is left unsanded where it intersects the fuselage. Rough sand

the airfoil by using cross grain strokes with the rough side of the sanding block.

Do not sand below the guide lines and leave a 1/16" radius on the leading and trailing

edges. Use spanwise strokes with the 60 grit paper to even out any ripples. Now

remove any sanding marks with the 220 grit side of the block. Cut the ailerons from

the lower wing; then cut the hinge slots and glue the lower wing into the fuselage.

The tail assembly is straightforward. Cut, shape and slot these surfaces for

the hinges, then glue the fin and the stab to the fuselage.

Efforts have been made to keep the hardware standard, but there are three pieces

that must be homemade. These are the two horns on the hook and the horn on the rudder.

The hook horns are made from 1/16 x 1/4" brass, available from any good hobby shop.

This heavy a piece is used so there is adequate contact with the hook to insure

a strong solder joint. Solder the right horn to the hook, but leave the left one

unsoldered until after the final assembly. The rudder horn can be made from the

same material or a lighter gauge. A homemade rudder horn is necessary as a conventional

horn will interfere with the elevator travel. Attach all horns to their respective

control surfaces. Install the control surfaces but do not glue the nylon hinges

in place, as the control surfaces are removed for finishing.

Mount the bellcrank; bend and install the pushrod. Now epoxy the hook release

guide tube to the fuselage. Bend the hook release wire, then bind and solder it

to the pushrod. The aileron and rudder push rods are made from 12" Du-Bro "Kwik-Links."

Insert the hook into the fuselage. It will probably be necessary to use one or two

between the hook horns and the fuselage for spacing. Slide the horn on the left

side of the hook, bend the Kwik-Links and temporarily install them. Solder the catch

on the hook. It should disengage the release wire with about 15 to 20 degrees down.

Mount the motor and tank and bend the throttle push rod to length. The engine we

recommend is the plain bearing Fox 36 RC. This motor is as good as any other and

is by far the easiest to install. The throttle arm is in the right place and moves

in the right direction (i.e., closes the throttle when moved forward) to permit

a straight, short pushrod between the bellcrank and the throttle. It may be necessary

to make a long throttle arm to slow down the closing action. The Fox has a very

fast throttle. Other engines may require some arrangement to get the push rod around

the tank and perhaps a link to reverse the pushrod direction. This is the kind of

trouble that a new Carrier flier would be well advised to avoid.

At this point, the plane is completely assembled except for the upper wing and

the struts. Check to see that all the controls function properly. The left aileron

will not work properly because the horn on the hook is not yet soldered. It can,

however, at least be verified that the pushrods are the correct length. Remove all

the controls, the motor, tank and landing gear; the model is now ready to finish.

I suppose every flier has his favorite finishing technique. Plain dope is probably

adequate, but an epoxy finish will hold up longer when high nitro fuels are used.

The method I use is as follows: Fill any nicks with vinyl spackling compound.

Sand the entire model smooth with 320 or 400 grit paper. Brush on two coats of clear

dope and sand smooth with 320 paper after each. Apply three brushed coats of dope

and talc filler and sand with 320 after each. Next, spray a very, very thin coat

of DuPont No. 30 auto primer. This can be thinned with dope thinner. Sand this lightly.

Now spray on colored epoxy. The primer is necessary as the epoxy will not adhere

well to dope. Elaborate spraying equipment is not needed. The PreVal sprayer coats

a dollar and one unit will paint a model the size of the Bipe. The epoxy should

be applied hot. Heat it in very hot water for half an hour before application -

this will greatly speed the drying and thereby reduce the chance of dust adhering

to the finish. Reinstall the motor tank, controls and landing gear, and glue on

the struts and upper wing.

The lines and handle are critical parts of the control system, and no matter

how careful a job has been done up to this point, the lines must be cut to the correct

length or only frustration will result. The lines must be cut so that the distance

from the center of the fuselage to the center of the grip is between 60 and 60.5

ft. First, cut the elevation lines so they satisfy your feel of level. Next, hold

the handle in a horizontal position so they satisfy your fell of level. Next, hold

the handle in a horizontal position so the elevation lines run parallel all the

way to the plane. The motor is now in its high speed position. Now with the trigger

pulled back, tie the throttle line so that it sags slightly more than the elevation

lines. Slightly more means "as little as possible without sagging less." Next before

the line ends are soldered, check to see that the system has a full range of throttle

movement. Lines that are not the correct length in relation to one another are the

biggest cause of trouble to a beginning Carrier flier. Minor adjustments in length

can be made by using different size line clips.

Flying

The model is now ready to fly. If this is your first Carrier ship, it would be

wise to contact an experienced Carrier flier, let him watch you fly and then offer

you his suggestions. Carrier does not require great flying skill and endless hours

of practice. The rules for Profile Carrier are very restrictive in an attempt to

keep the event simple. It is safe to say that if the engine is well broken in and

the control system is carefully adjusted, the Bipe will keep up with the best. If

you would like to send any comments or suggestions, please send them to me at 433

Arquilla Dr., Glenwood, 111., or to Don at 1119 Parkside Dr. N., Wyomissing, Pa.,

19610.

MO Biplane Plans

<click for larger version>

Notice:

The AMA Plans Service offers a

full-size version of many of the plans show here at a very reasonable cost. They

will scale the plans any size for you. It is always best to buy printed plans because

my scanner versions often have distortions that can cause parts to fit poorly. Purchasing

plans also help to support the operation of the

Academy of Model Aeronautics - the #1

advocate for model aviation throughout the world. If the AMA no longer has this

plan on file, I will be glad to send you my higher resolution version.

Try my Scale Calculator for

Model Airplane Plans.

Posted April 24, 2023

(updated from original post

on 12/11/2012)

|